CZ Sigma Purlin Roll Forming Machine

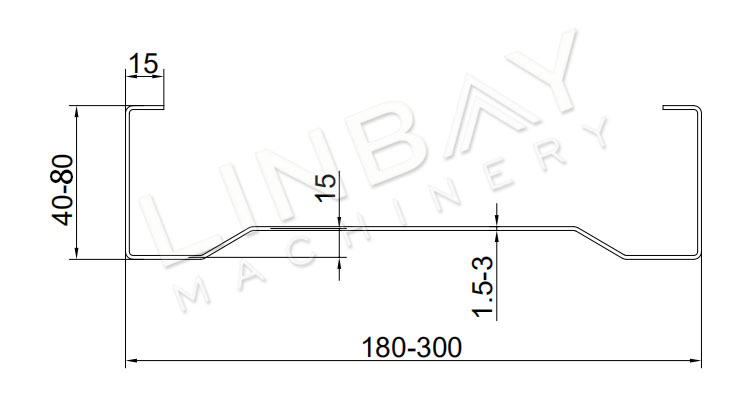

Linbay offers you the roll forming machine for C, Z and Sigma. Type C/U belts are known for their high strength and load capacity. They are used to support heavy loads such as roofs, crawl spaces, and bridge structures, they are usually used when they have less than 20% slope. The Z belt is lighter, has a greater capacity to bend giving as an advantage greater lateral resistance, they are usually used in the construction of walls, metal cladding and for roof slopes of 20% or greater. The Sigma profile (Σ-Purlin) is used as a cladding option as well as a support for roofs due to its greater resistance at lower heights.

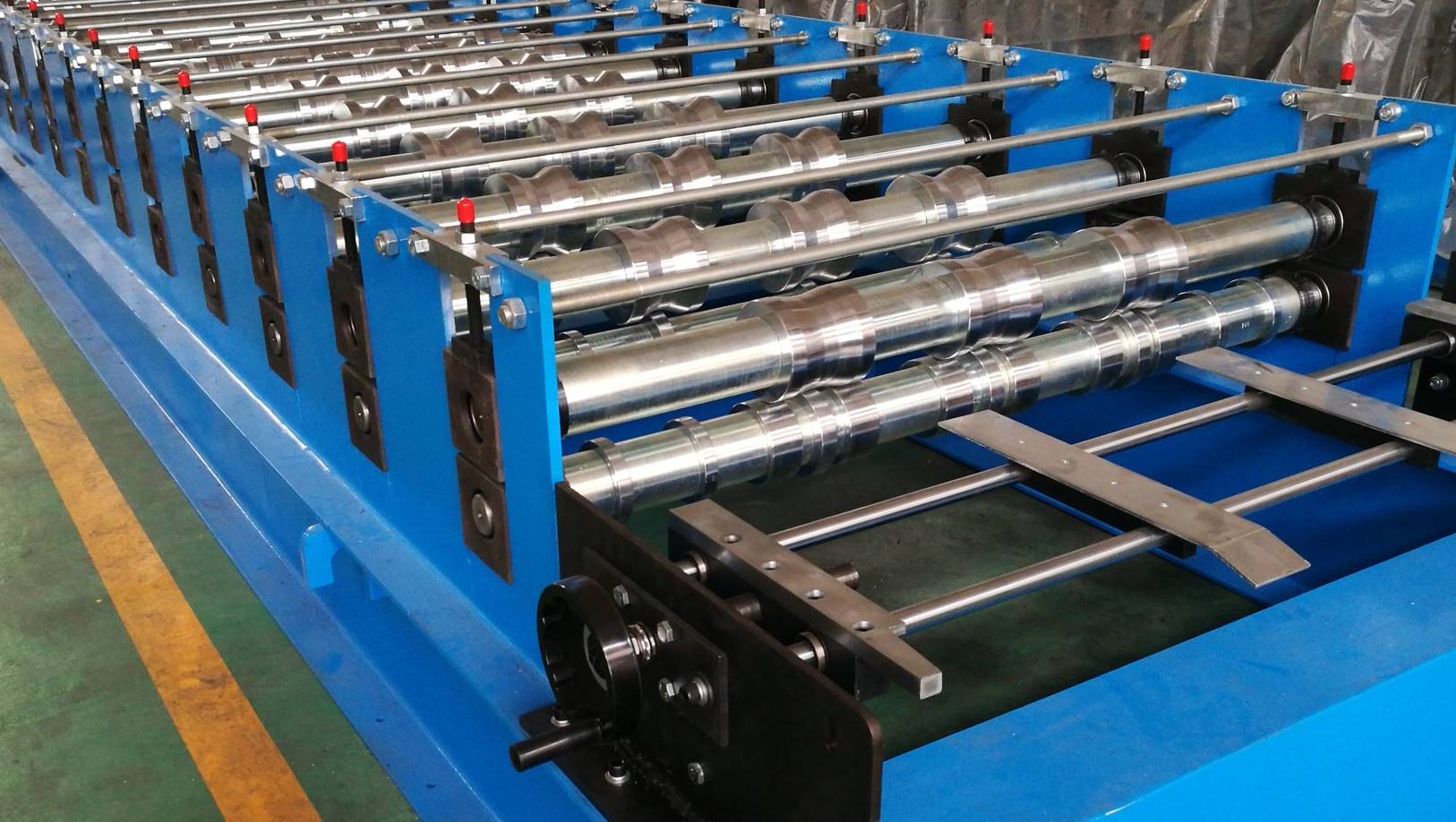

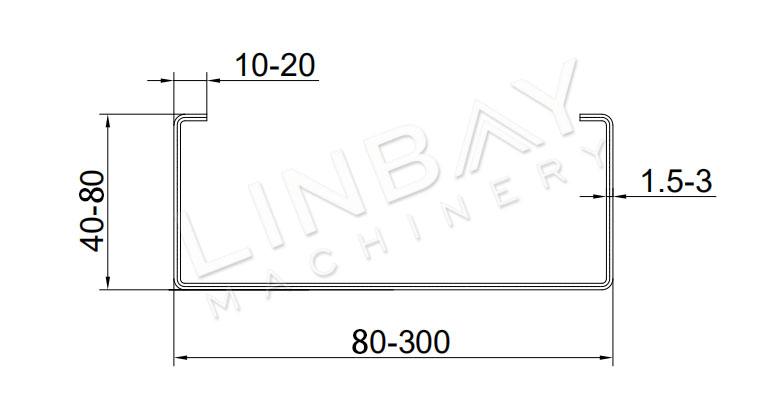

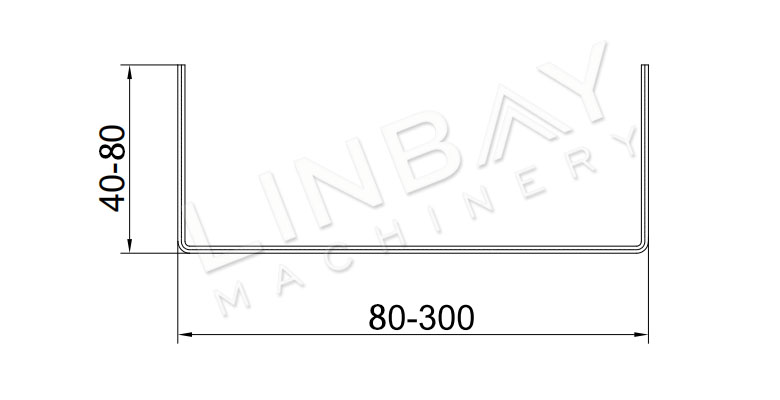

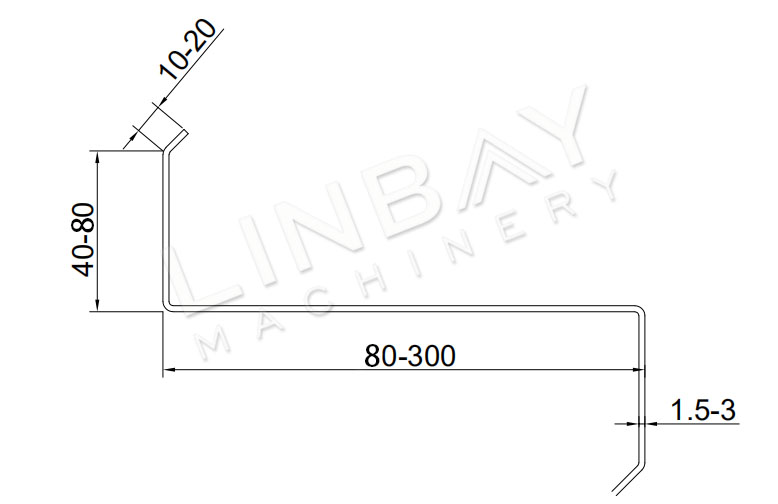

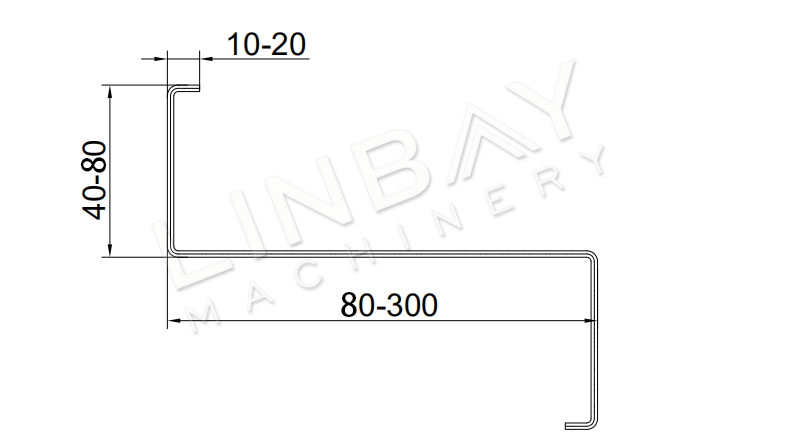

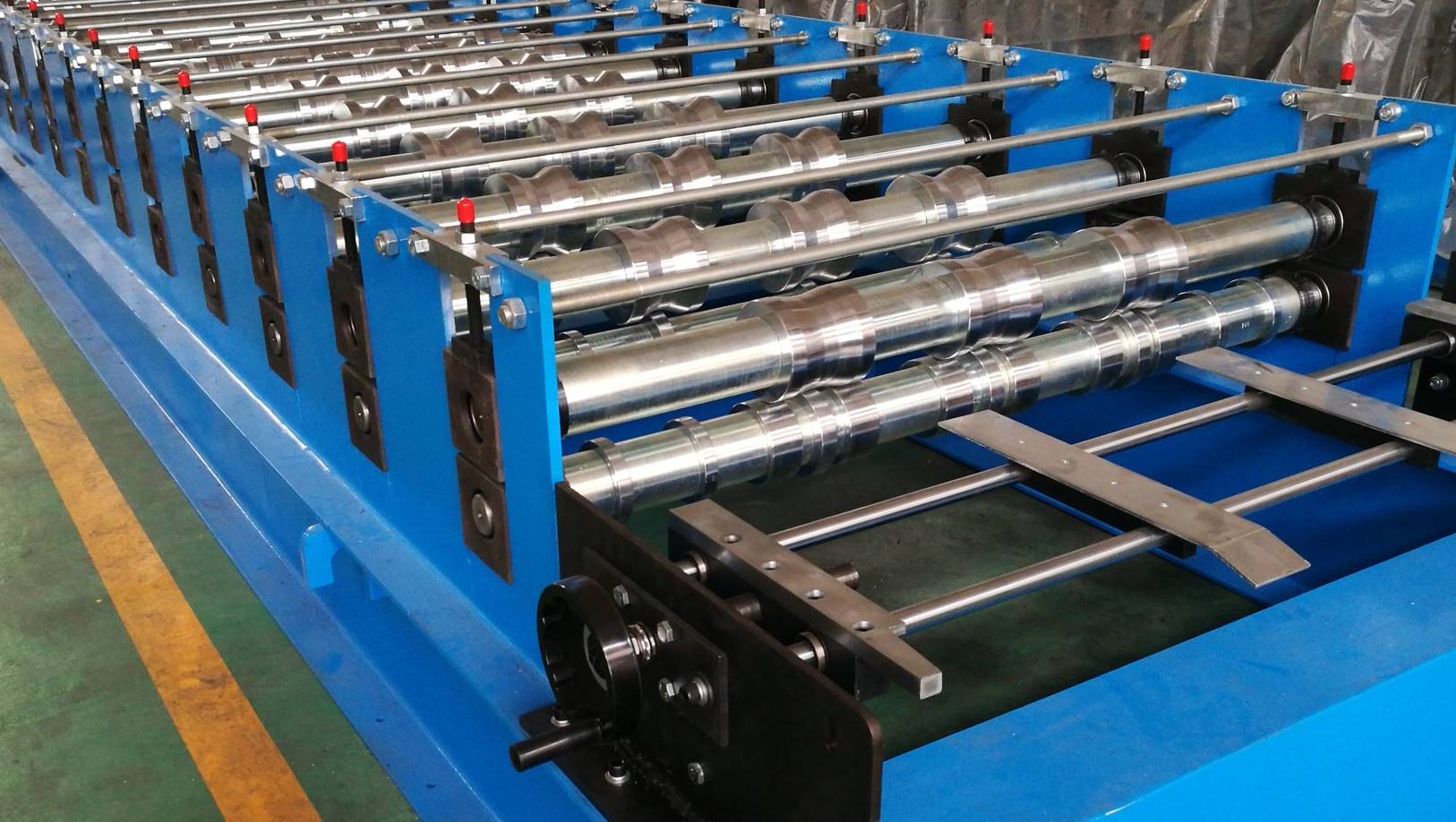

The machine has a speed from 10m/min to 20 m/min, the dimensions for this profile are from 100mm to 600mm wide, a height from 40mm to 100mm, for the lips in the Z profile you can choose to have an angle of 45 degrees or 90 degrees of doubles, With a measurement from 10 mm to 20mm, for the Sigma profile a height of 40 mm to 80mm is stipulated with a width of 180mm to 300mm, considering these measurements as a reference, if you look for some other measurement you can modify the design.

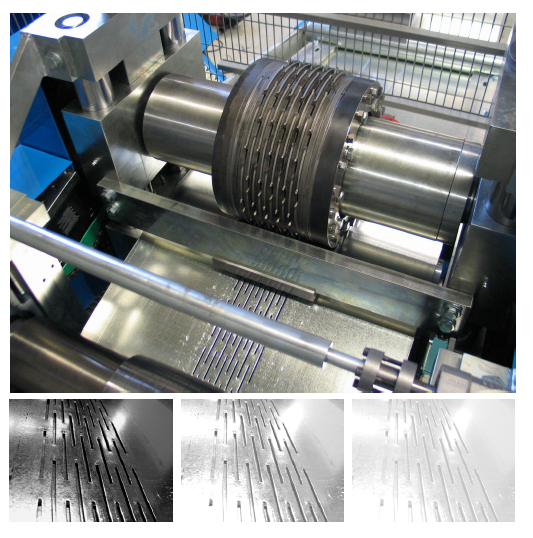

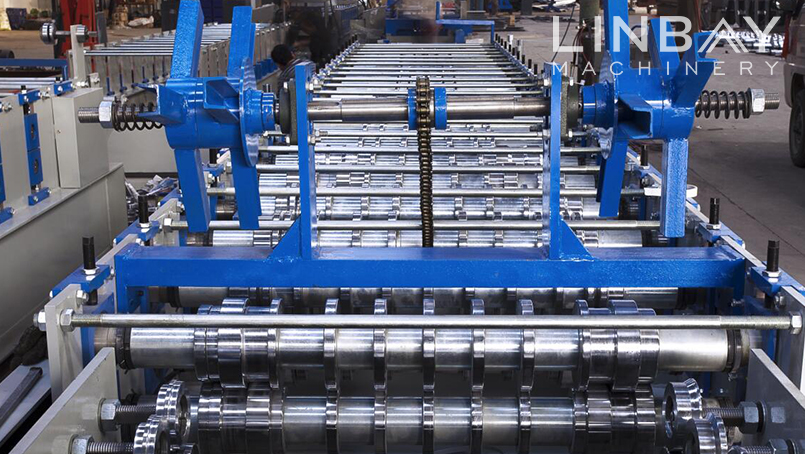

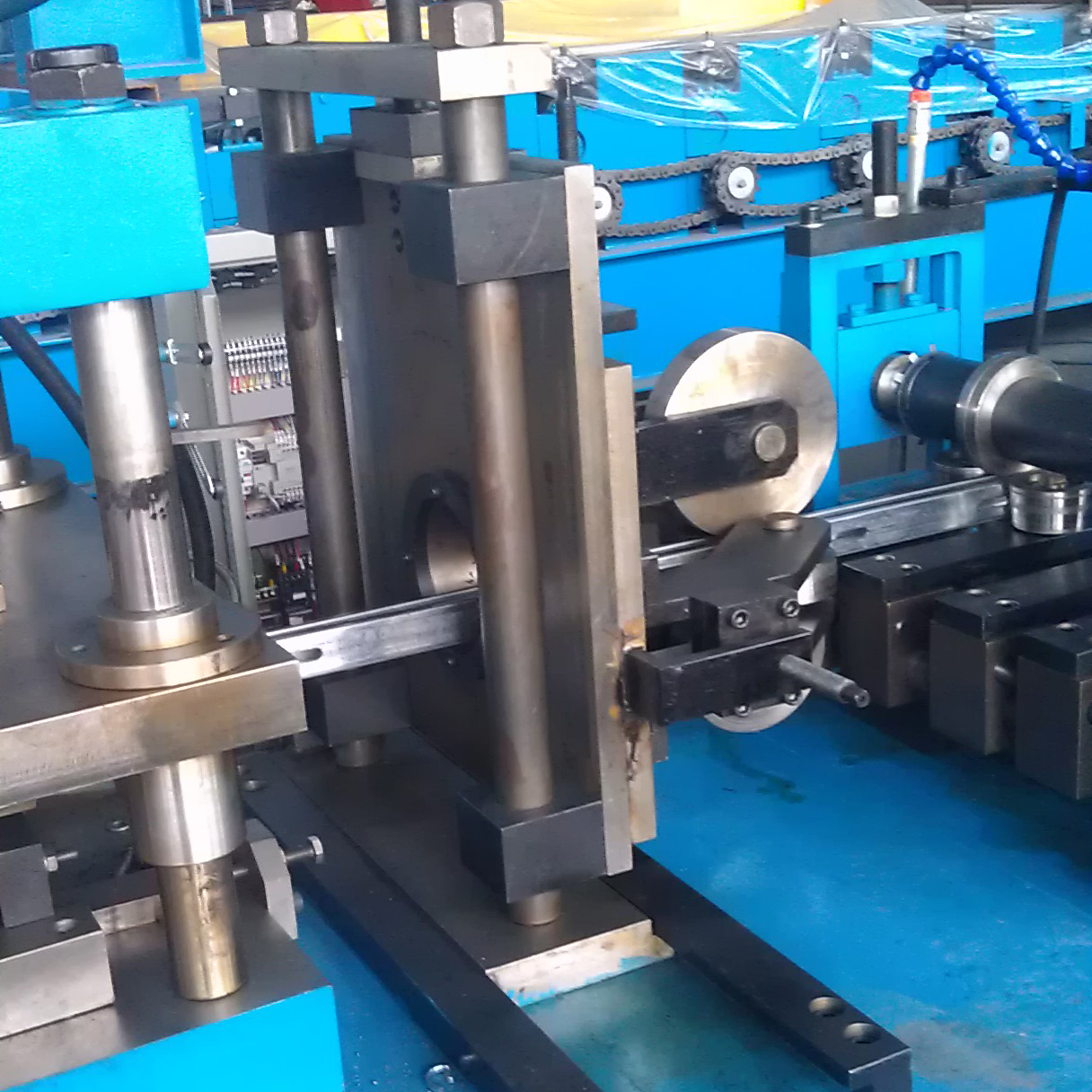

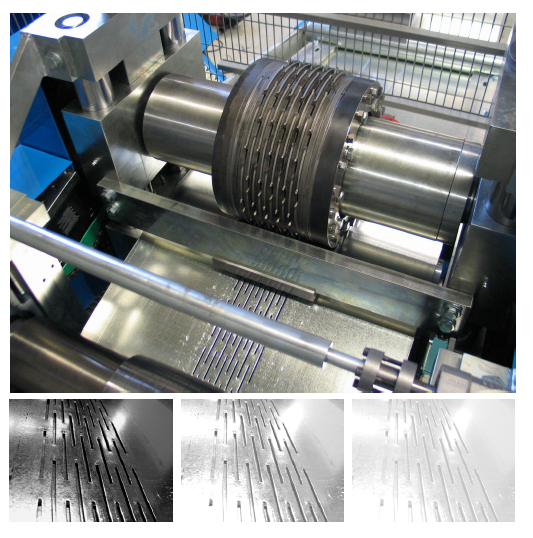

To make these changes we can offer two different configurations, if you are looking for something precise, practical and fast you can choose the self-regulating change rate, which allows us to make a measurement change from the screen of our cabinet in which with the help of the servomotor we can change the dimensions of our machine. If you do not choose the self-regulating gearbox, we have the option of changing the dimensions using spacers, increasing the time of change of size since it consists of changing the spacers between the rollers. If your design needs to be drilled we can give the option of a hydraulic press inside the machine or the alternative of using a punching machine before reaching the roll forming machine increasing the speed of it. Since they are two different profiles, to be the change from C to Z it consists of turning a crank which will change the angle that is sought to give the Z shape.

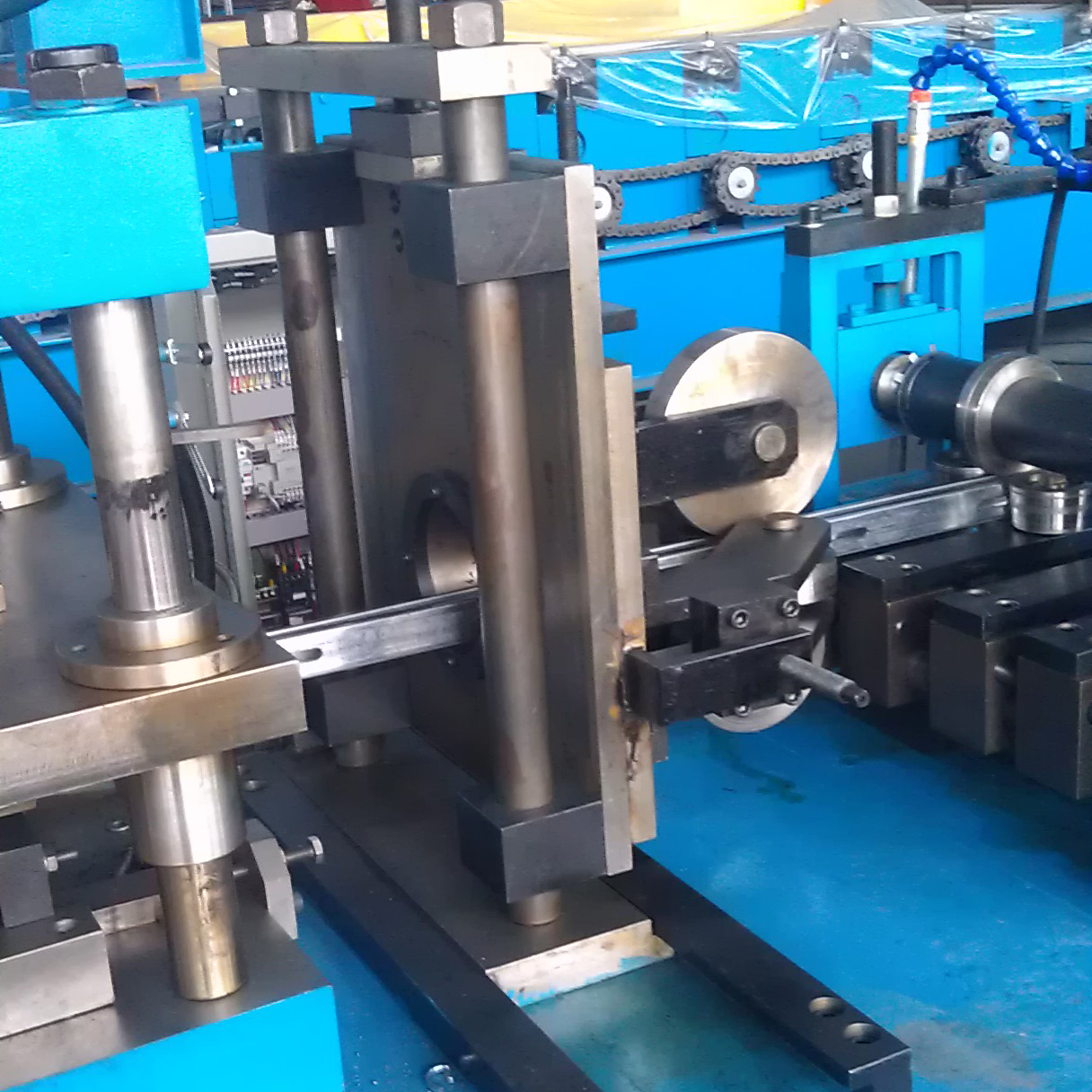

For the cutting of this design different options can be considered, a pre-cut, which consists of stopping the machine for a few seconds while making the cut at the beginning of the machine, the second option would be a cut at the end of the machine this can be with a fixed or movable base which helps to have a constant speed.

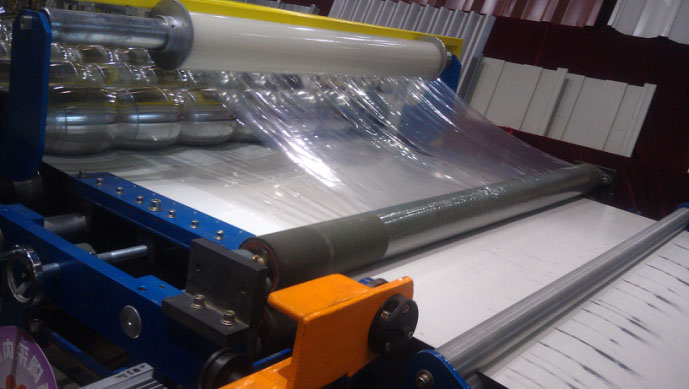

We can use galvanized steel, PPGI, carbon steel with a thickness of 1.5mm-3mm as required. If you are looking to create a design that is different from the current market, our team can help you make it possible by knowing your standards and requirements, thus offering you the different options that are most suitable for your company.

All our operating systems are translated into Spanish and English, as are the operating manuals, so that your work team can operate the machine efficiently and safely.

This C/Z/U/M purlin roll forming machine is our new innovation in 2018. This machine has been exported to Mumbai, India. This excellent machine could make C section, U section, M section and Z section purlins with thickness 1.5-4mm. The purlin line is equipped with servo feeder, leveler and automatic width-change and height-change system, also from C to Z only need to change 4 stations manually with change wheel. It could be operated whole line with one operator easily in 2 minutes. Linbay Machinery is your best choice for purlin roll forming solution.

This CZ purlin quick changeable roll forming machine is a mature production line. We have 10 years of experience in this machine. It’s more affordable, economic and it’s our best-seller. It adopts pre-cut system to avoid changing too many blades, which saves time for you. Sizes can be changed by motor automatically. Changing time from C to Z need 10 minutes. Linbay Machinery is your best choice for purlin roll forming solution.

Manual decoiler--feeding--forming machine--hydraulic cutting--out table

| Purlin Roll Forming Machine | ||

| Machinable Material : | A) Galvanized Coil | Thickness(MM): 1.5-3 |

| B) PPGI | ||

| C) Carbon steel Coil | ||

| Yield strength : | 250 - 550 Mpa | |

| Tensil stress : | G350 Mpa-G550 Mpa | |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Punching system : | Hydraulic punching station | * Punching press (Optional) |

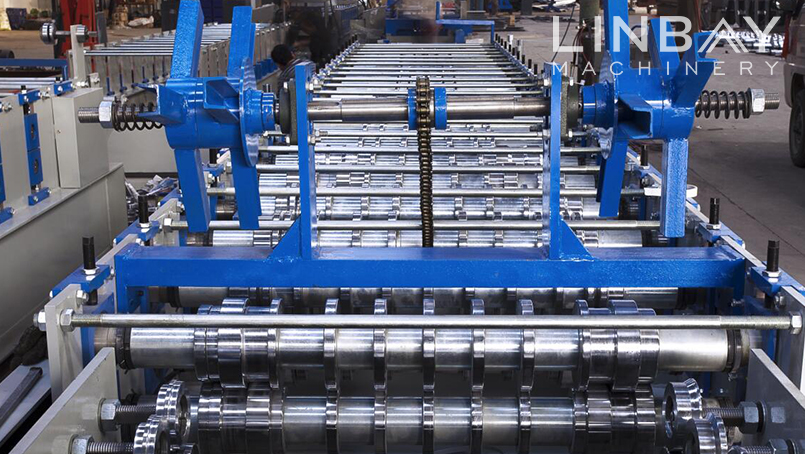

| Forming station : | 18-20 stations | |

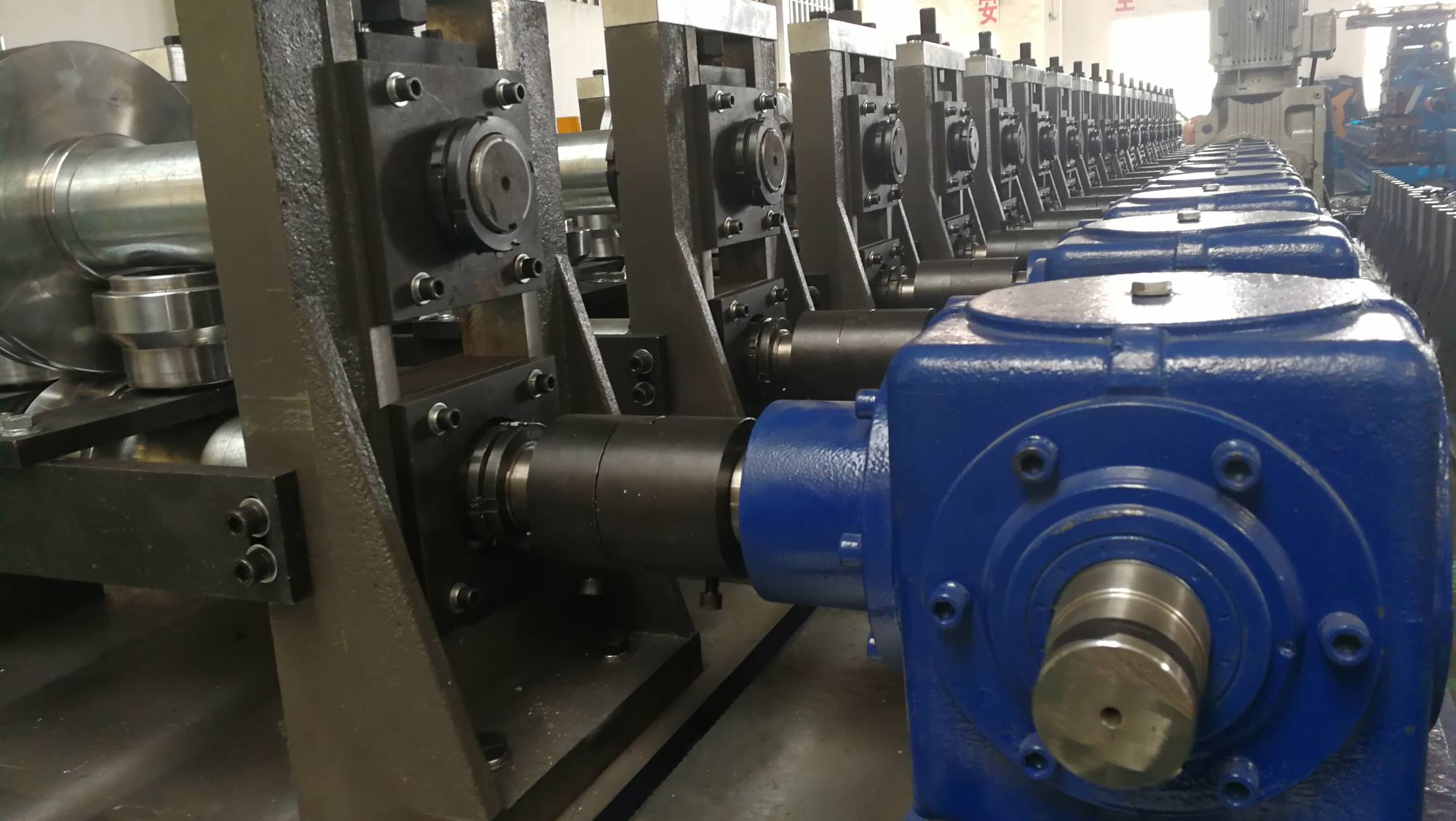

| Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens (Optional) |

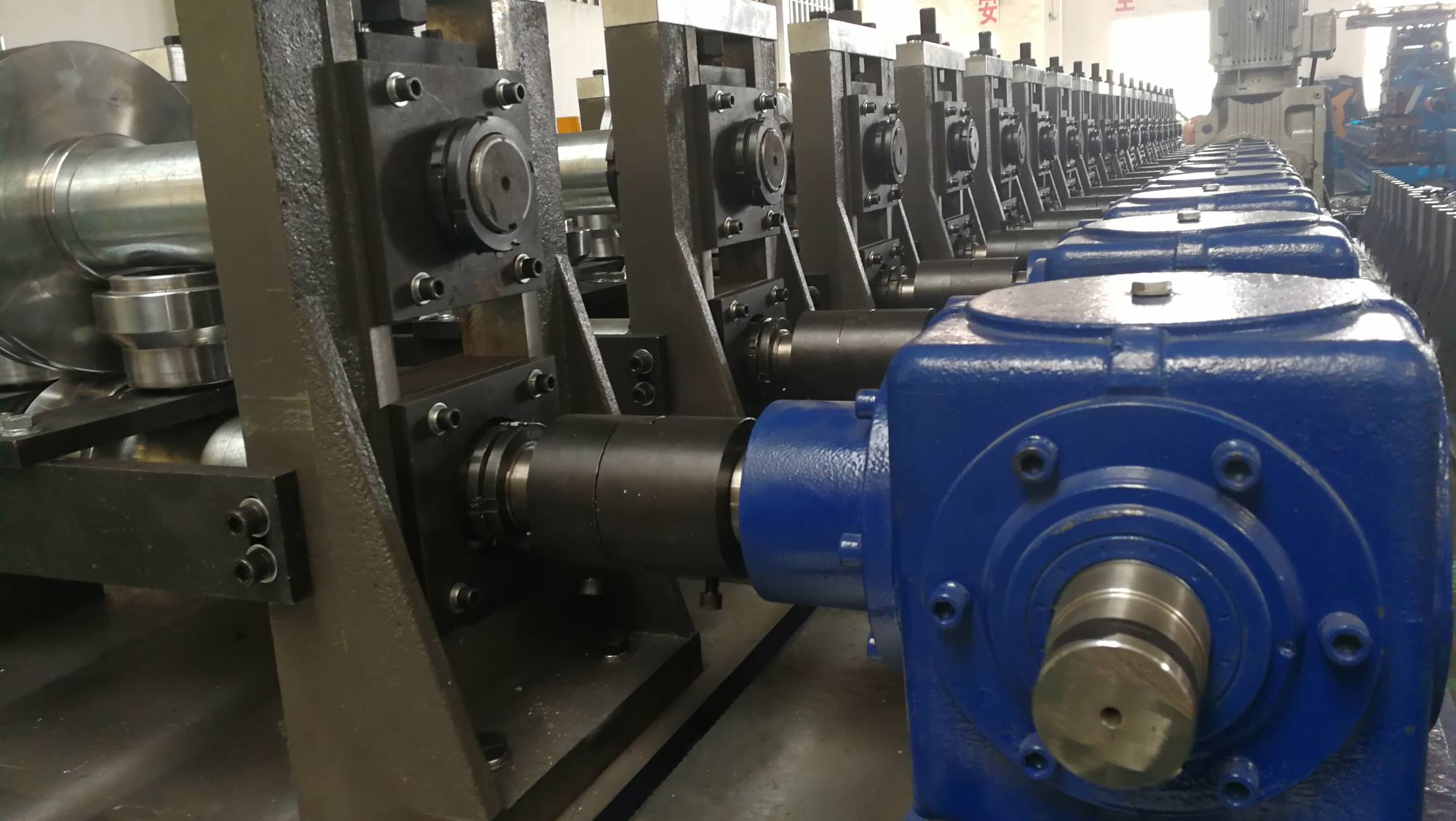

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Wall panel station | * Forged Iron station (Optional) |

| Forming speed : | 10-20 (M/MIN) | * Or according to your profile drawings |

| Rollers’ material : | Steel #45 | * GCr 15(Optional) |

| Cutting system : | Pre-cutting | * Post- universal cutting (Optional) |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

1. Q: Why buy a Linbay machine?

A: At Linbay we seek to establish long-lasting relationships by offering the best quality and price, as well as unparalleled experience and attention in the market. We have customer service in Mexico and China to solve any questions or inconveniences, backed by our 12 years of experience in the market.

2. Q: What is the delivery time?

A: The lead time is 60 to 80 days, during which we produce, assemble and test to ensure that the machine meets your expectations and required safety standards.

3. Q: How do I get started with my machine?

A: Upon receipt of your machine, an assembly tutorial and operation manual will be provided. We recommend a visit from our technician if this is your first time using a forming machine or if you have doubts about its operation. The technician will explain every detail and train your work team.

4. Q: What process do I need to follow to buy a machine?

A: You can start by contacting our sales team via message or email. Afterwards, we will discuss which type of machine best fits your needs and standards. If you want to know more about our company, you can visit our office in Mexico or our factory in China for a tour and observe our manufacturing process. Once you decide to join the Linbay family, we will start manufacturing your machine after signing the contracts and making a 30% down payment.

5. Q: What determines the speed of the forming machine?

A: The speed depends on the requirements of your profile, as well as the structure of the machine you can choose between panel or forged steel type Torri which gives us greater stability. If the gearbox-type transmission system is chosen, we will obtain improved performance and less wear. The use of a hydraulic unwinder is recommended, which allows for a considerate speed as well as greater safety at the time of operation.

-

Others

-

scrap collector

-

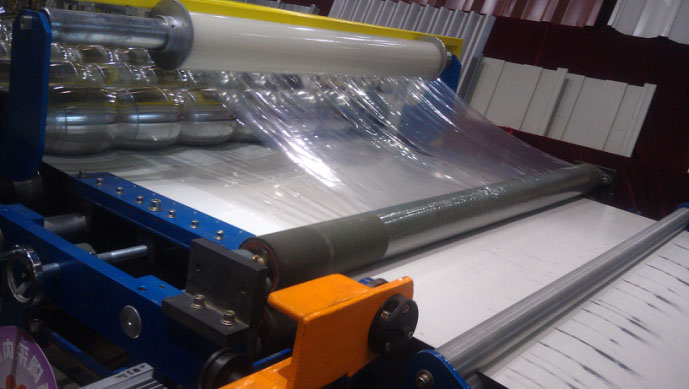

pasting

-

mould change

-

guiding head

-

sooling system

-

-

Out table

-

non-powered

-

auto stacker

-

-

Cutting

-

fixed saw cutting

-

flying shear

-

universe cutting

-

-

Driving

-

chain drive

-

gearbox drive

-

gearbox drive with coupling

-

-

Stands

-

wall panel stands

-

torri stands

-

forged iron stands

-

wall panel for C purlin

-

-

Punching

-

hydraulic punching station

-

Punching press

-

roller punching

-

-

Feeding

-

leveling

-

servo feeding

-

-

Decoiler

-

manual decoiler

-

hydraulic decoiler

-

double head decoiler

-