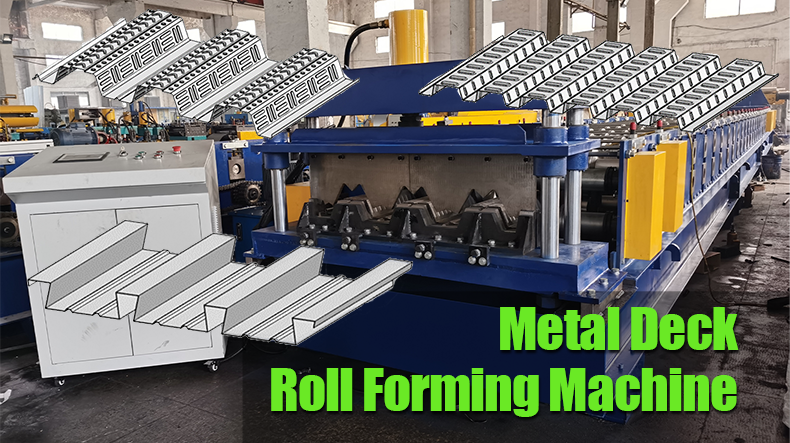

Metal Deck Roll Forming Machine

Currently the most used profiles in the market are,

The 15 steel whose thickness is from 0.6mm to 1.2mm (Gauge 24 to 18), this profile has an effective width of 915mm and a cant of 38mm, this profile acts as positive reinforcement steel and formwork, this profile is manufactured under the standards of the American National Standards Institute (ANSI) and Steel Deck Institute (SDI) version 2007.

The 25 steel with a thickness of 0.6mm to 1.2mm (Gauge 24 to 18), this profile has an effective width of 914.4mm and a cant of 63mm, this profile is manufactured under the standards of the American National Standards Institute (ANSI) and Steel Deck Institute (SDI) version 2011.

The 30 steel whose thickness is from 0.6mm to 1.2mm (Gauge 24 to 18), this profile has an effective width of 915mm and a cant of 76.2mm which has a greater load capacity increasing the maximum unshored span and its resistance as a composite slab, this profile is manufactured under the standards of the American National Standards Institute (ANSI) and Steel Deck Institute (SDI) version 2011.

For the production of any of these three types, we can use galvanized, galvalume and painted polyester steel (Zintro, zintroalum and pintro), with a speed of up to 15m/min, the proposal is made with panel and chain structure as a transmission system, if you are looking to increase speed and have greater stability in the axles, it is recommended to use wrought iron and gearboxes.

If you are looking to create a design that is different from the current market, our team can help you make it possible by knowing your standards and requirements, thus offering you the different options that are most suitable for your company.

All our operating systems are translated into Spanish and English, as are the operating manuals, so that your work team can operate the machine efficiently and safely.

Description:

This steel deck roll forming machine we exported it to India on 2016. Its height of profile drawing is 78mm, so we adopted 32 forming stations and 2 embossing stations. We also have exported longer steel deck roll forming machine to Angola, which has 38 forming stations.

Decoiler--Hydraulic cut--Rollers--Roller former 1--Roll former 2--Out Table

|

Metal Deck Roll Forming Machine |

||

|

Machinable Material : |

A) Galvanized Coil |

Thickness(MM):0.6-1.2 or 1-1.5 |

|

B) PPGI |

||

|

C) Carbon steel Coil |

||

|

Yield strength : |

250 - 550 Mpa |

|

|

Tensil stress : |

350 Mpa-550 Mpa |

|

|

Nominal forming speed(M/MIN): |

0-20 |

* Or according to your requirement (Optional) |

|

Forming station : |

26 stands |

* According to your profile drawings (Optional) |

|

Decoiler : |

Manual decoiler |

* Hydraulic decoiler (Optional) |

|

Punching system |

No |

* Hydraulic punching or Punching press (Optional) |

|

Main machine motor brand : |

Sino-Germany Brand |

* Siemens (Optional) |

|

Driving system : |

Chain drive |

* Gearbox drive (Optional) |

|

Machine structure: |

Wall panel station |

* Forged Iron station or torri stand structure (Optional) |

|

Rollers’ material : |

Steel #45 |

* GCr 15 (Optional) |

|

Cutting system : |

Post-cutting |

* Pre-cutting (optional) |

|

Frequency changer brand : |

Yaskawa |

* Siemens (optional) |

|

PLC brand : |

Panasonic |

* Siemens (optional) |

|

Power supply : |

380V 50Hz |

* Or according to your requirment |

|

Machine color : |

Industrial blue |

* Or according to your requirment |

1. Q: Why buy a Linbay machine?

A: At Linbay we seek to establish long-lasting relationships by offering the best quality and price, as well as unparalleled experience and attention in the market. We have customer service in Mexico and China to solve any questions or inconveniences, backed by our 12 years of experience in the market.

2. Q: What is the delivery time?

A: The lead time is 60 to 80 days, during which we produce, assemble and test to ensure that the machine meets your expectations and required safety standards.

3. Q: How do I get started with my machine?

A: Upon receipt of your machine, an assembly tutorial and operation manual will be provided. We recommend a visit from our technician if this is your first time using a forming machine or if you have doubts about its operation. The technician will explain every detail and train your work team.

4. Q: What process do I need to follow to buy a machine?

A: You can start by contacting our sales team via message or email. Afterwards, we will discuss which type of machine best fits your needs and standards. If you want to know more about our company, you can visit our office in Mexico or our factory in China for a tour and observe our manufacturing process. Once you decide to join the Linbay family, we will start manufacturing your machine after signing the contracts and making a 30% down payment.

-

Out table

-

Non-powered

-

Auto-stacker

-

-

Cutting

-

Saw cutting

-

fast flyting cutting

-

-

Driving

-

chain driving system

-

gearbox driving system

-

Gearbox with couplings

-

-

Stands

-

Torri Stands

-

Forged Iron Stands

-

Wall Panel

-

ruler

-

-

Punching

-

Hydraulic punching station

-

Fast Roller Punching system

-

Punching press

-

-

Feeding

-

Servo feeder

-

Leveler

-

-

Decoiler

-

Motorized&Hydraulic decoiler

-

Double head motorized decoiler

-

Manual Decoiler

-

.jpeg?x-oss-process=image/resize,w_100/quality,q_100)