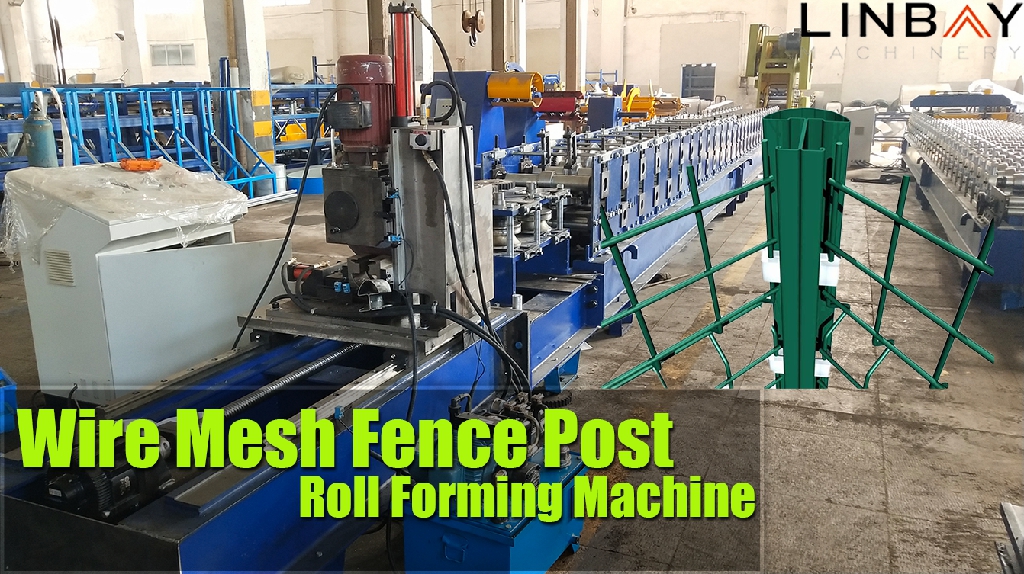

Wire Mesh Fence Post Roll Forming Machine

Description

Linbay offers the wire mesh fence post also known as Peach Post, whose outside of the post is oval, and the inside bends outward to create a U-shaped hook. It has several notches along the sides for easy installation of fence panels. The size of the notches must match the size of the panel mesh. In addition, the hook structure is compact, which helps prevent theft.

For this profile, a thickness of 1-1.2mm will be used, using galvanized steel, cold rolled or hot rolled steel as raw material. We can offer you two different versions of this machine which can fit your budget and needs.

1.With a speed of 4m/min, this roll forming machine is more suitable for those companies that do not have much space in their plant, and that are looking for a production of up to 2400 pieces per day, for this design a manual unwinder will be used, a hydraulic punching station at the beginning and another at the end, with fixed hydraulic cutting.

2.With a speed of up to 8m/min, for companies looking for a production of up to 4800 pieces per day, this design is made up of a hydraulic unwinder with flattener for the material, an 80Ton die cutter which will have a servo feeder which will give us great precision when drilling, after going through a former, It will be cut with a saw-type disc which will be in motion.

If you are looking to create a design that is different from the current market, our team can help you make it possible by knowing your standards and requirements, thus offering you the different options that are most suitable for your company.

All our operating systems are translated into Spanish and English, as are the operating manuals, so that your work team can operate the machine efficiently and safely.

Roll forming machine has a big range application, Linbay Machinery has made roll forming machines for metal fence post. Linbay roll forming machine can make wire mesh fence post, metal fence post for wood fence. Wire mesh fence post normally uses peach type profile, thickness is 1-1.2mm, cold rolled or hot rolled steel, galvanized steel, Peach post curved fence is widely used in express highway, railway, airport, the city roads, grand square and flower and grass fences etc. It not only protects the safety of vehicles and pedestrian, but also beautifies the space environment. The metal posts for wood fence system can last for decades that allow the beauty of the wood to remain prominent, while providing the superior strength of metal. Popular thickness is 3mm.

LINBAY roll forming machine can make lots of post profiles, guardrail post, solar photovoltaic stents, vineyard post etc.

Wire Mesh Fence Post

Z Post/Metal Fence Post for wood fencing system

Metal Fence Post for wood fencing system

Introduction:

This wire mesh fence post roll forming machine has a basic configuration: manual decoiler-hydraulic chamfer-roll former-hydraulic punch-hydraulic post cut-out table. At the feeding part of the roll forming machine, we make a chamfer device, this is easy for post cutting. The punch system equipped on the roll former, it can reduce the machine’s cost it’s an economic choice, but the working speed will be low, around 4m/min. Customer can choose Case B’s machine configuration if you want a fast speed roll forming machine.

Introduction:

This wire mesh fence post roll forming machine has a high speed and precision configuration: manual decoiler- leveler-servo feeder-punch press- roll former-flying saw cut-out table. The servo feeder system uses Yaskawa servo motor to control the feeding length for the punch press, then you will have a high-precision at the holes punch part. The 80Tons press can offer a fast punch speed compared hydraulic punch system, it can double the production, up to 8m/min. Normally we suggest our customer buy Yangli brand press JH21-80. The roll former part we use 26 forming stations to ensure the profile prefect and 2 riveting rollers to make profile together. With this fast speed, we put a flying saw cut device, which will not stop the roll former when cutting. The saw cut has a smaller burr and wastage(around 3mm). This is the best roll forming machine solution we suggest for wire mesh fence post.

Linbay make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles.

Whole Production Line of Wire Mesh Fence Post Roll Forming Machine

| Metal Fence Post Roll Forming Machine | ||

| Machinable Material : | A) Galvanized Steel | Thickness(MM): 0.7-1.3, 3mm |

| B) Black steel | ||

| C) Carbon steel | ||

| Yield strength : | ≤350 Mpa | |

| Tensil stress : | ≤350 Mpa | |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Punching system : | Hydraulic punching station | * Punching press 80Tons (Optional) |

| Forming station : | 26 | |

| Mian machine motor power: | 2*11KW | |

| Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens Beide (Optional) |

| Driving system : | Chain drive | |

| Machine structure: | Wall panel type | * Forged Iron station (Optional) |

| Working speed : | 4 (M/MIN) | * 6-8m/min (Optional) |

| Rollers’ material : | 45 steel | * GCr15 (Optional) |

| Cutting system : | Post hydraulic cutting | * Flying saw cutting (Optional) |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz 3ph | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

1. Q: Why buy a Linbay machine?

A: At Linbay we seek to establish long-lasting relationships by offering the best quality and price, as well as unparalleled experience and attention in the market. We have customer service in Mexico and China to solve any questions or inconveniences, backed by our 12 years of experience in the market.

2. Q: What is the delivery time?

A: The lead time is 80 to 100 days, during which we produce, assemble and test to ensure that the machine meets your expectations and required safety standards.

3. Q: How do I get started with my machine?

A: Upon receipt of your machine, an assembly tutorial and operation manual will be provided. We recommend a visit from our technician if this is your first time using a forming machine or if you have doubts about its operation. The technician will explain every detail and train your work team.

4. Q: What process do I need to follow to buy a machine?

A: You can start by contacting our sales team via message or email. Afterwards, we will discuss which type of machine best fits your needs and standards. If you want to know more about our company, you can visit our office in Mexico or our factory in China for a tour and observe our manufacturing process. Once you decide to join the Linbay family, we will start manufacturing your machine after signing the contracts and making a 30% down payment.

-

Out table

-

Non-powered

-

Auto-stacker

-

-

Cutting

-

Saw cutting

-

fast flyting cutting

-

-

Driving

-

chain driving system

-

gearbox driving system

-

Gearbox with couplings

-

-

Stands

-

Torri Stands

-

Forged Iron Stands

-

Wall Panel

-

ruler

-

-

Punching

-

Hydraulic punching station

-

Fast Roller Punching system

-

Punching press

-

-

Feeding

-

Servo feeder

-

Leveler

-

-

Decoiler

-

Motorized&Hydraulic decoiler

-

Double head motorized decoiler

-

Manual Decoiler

-