3” Stainless Steel Trailer Tank Curved Omega Roll Forming Machine

Description

Linbay offers the forming machine for omega type reinforcement for pipe tank, this reinforcement must have an omega type profile, in other cases it can be type U, C and T. In addition to the profile, the piece must have a circular shape since it will be the support of the pipe, preventing it from opening, the client requested that it be manufactured 3mm thick for stainless steel.

This being a custom design each design will be subject to modifications, for this machine we use a 10 ton hydraulic decoiler, a 125 wrought iron structure, Z180 model gearboxes, 100mm diameter shafts for the rollers, all this is required to be able to mold the profile correctly. 18 forming stations are needed, with a speed of up to 12m/min depending on the length of each part.

If you are looking to create a design that is different from the current market, our team can help you make it possible by knowing your standards and requirements, thus offering you the different options that are most suitable for your company.

All our operating systems are translated into Spanish and English, as are the operating manuals, so that your work team can operate the machine efficiently and safely.

Brief Introduction of 3MM Stainless Steel Trailer Tank Curved Omega Profile

These curved profiles are used as machine elements or pipes for different media in a variety of industries such as automotive, chemical, air traffic, construction and food and beverage.

Compared to other profiles, bending profiles represent the most unique part of it. Depending on the requirements for bending radius and dimensional accuracy, different machines and different methods are used. (Note: The production process described here is mainly for 3 mm stainless steel material.)

The specific configuration of each machine needs to be individually designed according to your profile and requirements. The bending section here we use an integral wall panel structure, the gearbox drive provides the power transmission and the curvature of the bending can be adjusted according to the required radius. In addition to OMEGA, other profiles such as T-, U- or C-profiles (channels) and stainless steel angles can also be bent to a specific radius.

In Mexico, there are many similar trailer tanks on the streets, which transport water, milk, petrol, etc. The bent OMEGA profile we have made is used for the repair and reinforcement of trailer tank bodies.

For this 3MM stainless steel trailer tank curved omega roll forming machine, we also have other related machines for reference.

1. 3MM Galvanized steel curved omega roll forming machine

2. Trailer tank fender roll forming machine

Machine details

This production line working speed is around 0-10m/min according to cutting length, the forming speed is around 0-12m/min adjustable.

Note: This machine configuration is based on 3mm(11 guage) stainless steel profile. The specific configuration should according to your profile.

Flow chart

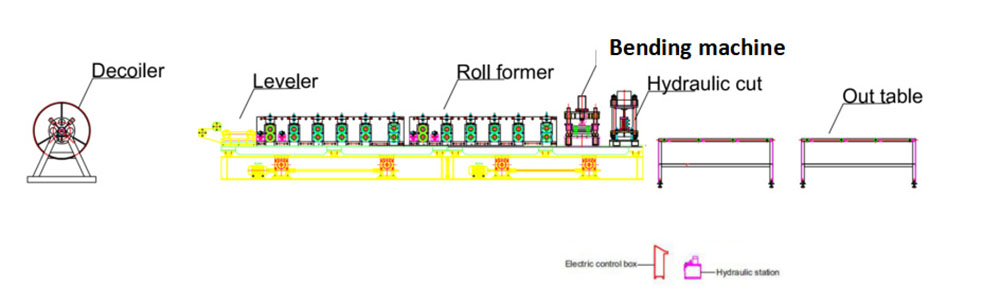

10 ton Hydraulic decoiler-Guiding-Leveler-Roll former-Bending machine-Hydraulic cut

Brief Introduction of 3MM Stainless Steel Curved Omega Roll Forming Machine

The curved omega roll forming machine has been designed for producing 3mm stainless steel omega profile for trailer tanks to reinforce.

Main components for this omega roll forming machine consists of a 10 ton hydraulic decoiler, guide, integrated leveler, main roll forming machine, bending machine, shearing, hydraulic stations, PLC control cabinet and out tables.

Due to the material and the thickness, the more specific configurations are 10 ton hydraulic decoiler, 125 Thickness Model iron cast structure, Z180 Thickness Model gear-box drive, 45kw motor power, Cr12Mov material rollers, φ100mm diameter roller shaft. Because of the 3MM stainless steel will require much more power to do the formation, iron cast can supply the strongest way to frame the whole line, and gear box can help offer the most stable pressure bearing function. What’s more, the big motor, great brilliant roller material and big diameter shaft, all of them is for the same pursuit, that is to enhance the whole production lines stability and intensity.

|

3MM Stainless Steel Curved Omega Roll Forming Machine |

|||

|

NO. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Cold-rolled steel, Galvanized steel, PPGI, stainless steel |

|

|

Thickness(mm):3mm |

|||

|

Yield strength: 250 - 550MPa |

|||

|

Tensile stress( Mpa):G350Mpa-G550Mpa |

|||

|

2 |

Nominal forming speed(m/min) |

0-12m/min |

Or according to your requirement |

|

3 |

Forming station |

18 |

According to your profile |

|

4 |

Bending station |

3 |

According to your profile |

|

5 |

Decoiler |

10 ton hydraulic decoiler |

According to your profile |

|

6 |

Main machine motor |

45kw Sino-German Brand |

Siemens |

|

7 |

PLC brand |

Panasonic brand |

Siemens/Delta |

|

8 |

Inverter brand |

Yaskawa brand |

Delta |

|

9 |

Driving system |

Gearbox drive Thickness Model Z180 |

Chain drive |

|

10 |

Rollers’ materail |

Cr12Mov |

Steel #45/GCr15 |

|

11 |

Station structure |

Forged Iron station Thickness Model 125 |

Wall panel structure |

|

12 |

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

|

15 |

Contactor |

Schneider brand |

Or according to your requirement |

Description

1. Q: Why buy a Linbay machine?

A: At Linbay we seek to establish long-lasting relationships by offering the best quality and price, as well as unparalleled experience and attention in the market. We have customer service in Mexico and China to solve any questions or inconveniences, backed by our 12 years of experience in the market.

2. Q: What is the delivery time?

A: The lead time is 80 to 100 days, during which we produce, assemble and test to ensure that the machine meets your expectations and required safety standards.

3. Q: How do I get started with my machine?

A: Upon receipt of your machine, an assembly tutorial and operation manual will be provided. We recommend a visit from our technician if this is your first time using a forming machine or if you have doubts about its operation. The technician will explain every detail and train your work team.

4. Q: What process do I need to follow to buy a machine?

A: You can start by contacting our sales team via message or email. Afterwards, we will discuss which type of machine best fits your needs and standards. If you want to know more about our company, you can visit our office in Mexico or our factory in China for a tour and observe our manufacturing process. Once you decide to join the Linbay family, we will start manufacturing your machine after signing the contracts and making a 30% down payment.

More details for the machine