Highway Guardrail Roll Forming Machine

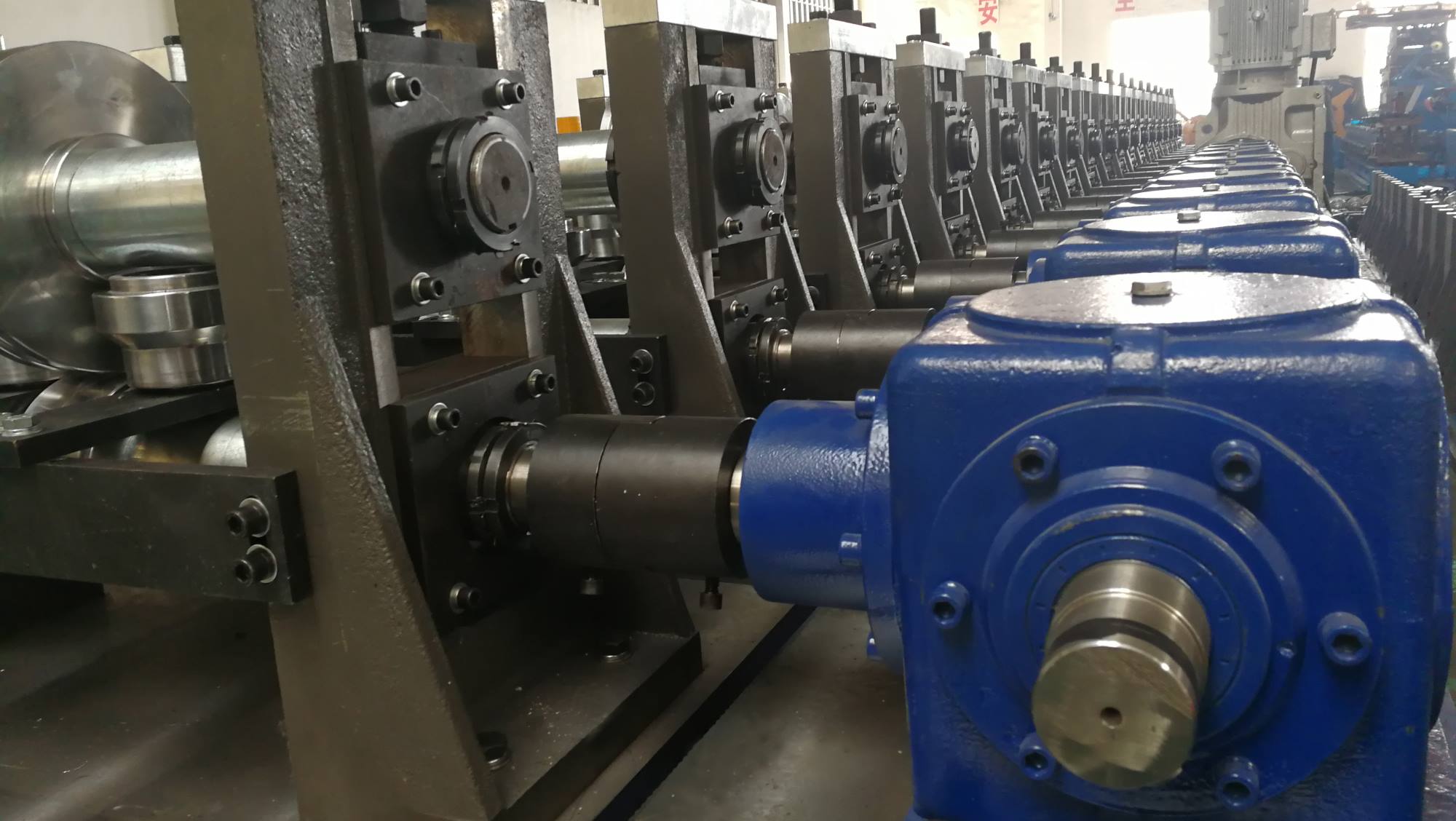

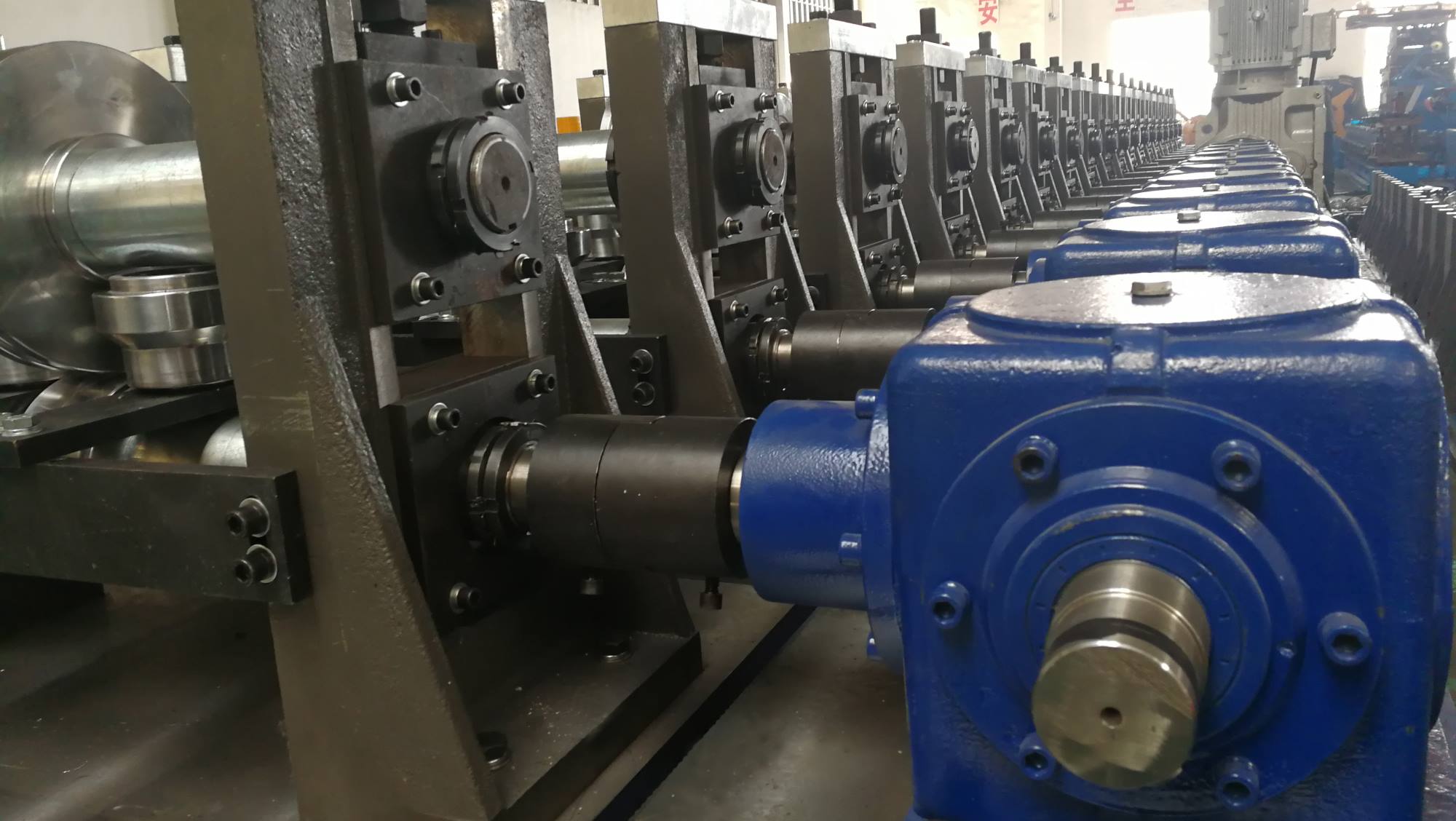

The machine can produce the design of 2 waves with a width of 309.59mm and 83.46mm height or 3 waves with a width of 506mm and a height of 85mm, for them we need to change the distance of the guides, as well as adjust 5 stations. The machine has a speed of 6m/min, producing one part of 4m and half of the second. For this model it was necessary to make a hydraulic punching, being a low gauge material (8-12) a wrought iron structure must be used, with a gearbox type transmission system. The use of a hydraulic unwinder is recommended since the coil can weigh up to 10 tons.

There is the option of using pre-cut where we can have up to a speed of 12 m/min since it is before forming, the machine should not stop every time drilling is due, this being the reason why the speed decreases, as well as does not cause waste, if you opt for post-cutting, It will have a slower speed, as well as a waste of 18mm-20mm per cut. When a pre-cut is done, the only disadvantage is that we cannot make very short pieces, as well as its high price compared to post-cut.

For this profile we can choose a type of galvanized steel, cold rolled or hot-rolled, with a thickness of 2.7mm to 4mm. Being a very heavy material due to its lengths, it is best to incorporate a stacker car which is responsible for collecting all the parts that come out of the machine.

If you are looking to create a design that is different from the current market, our team can help you make it possible by knowing your standards and requirements, thus offering you the different options that are most suitable for your company.

All our operating systems are translated into Spanish and English, as are the operating manuals, so that your work team can operate the machine efficiently and safely.

Highway Guardrail Roll Forming Machine can make W beam guardrail, thrie beam guardrail, also can be designed as two waves or three waves profiles in one machine just need to add some stations at the end of the machine.

We had experience of Russian type Guardrail, there are four lines totally:① two/three wave guardrail roll forming machine, ② U post roll forming machine,③ connection punching line and ④end terminal punching line.

Also we have experience of producing guradrail roll forming machines can meet different standards :

AASHTO M180--American standard

RAL RG620--Germany standard

BS EN-1317-- European standard

AS/NZS 3845:1999--Australian standard

Two/Three Wave Roll Forming Machine: We have two solutions for you.

2. Hydraulic decoiler-Leveling-Servo feeder-Punching-Cutting-Platform-Roll forming machine-Out table

3. Special for Turkish two wave guardrail drawing(meet EN 1461:2009 STANDARD)

Hydraulic decoiler-Guide-Leveling-Roll forming machine-Hydraulic punch-Hydralic cut-Shrink mould-Out table

We have experience of exporting our guardrail roll formers to Russia, Saudi Arabia, Turkey, Indonesia etc. And we have a Chinese government project. We provide machine and guardrails to our government. You could see our producing line in new factory, if you visit us.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles.

|

Two Waves/Three Waves Highway Guardrail Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil |

|

|

|

|

Thickness(mm):4-5 |

|

|

|

|

Yield strength: 250 - 550MPa |

|

|

|

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

|

|

2 |

Nominal forming speed(m/min) |

15 |

Or according to your requirement |

|

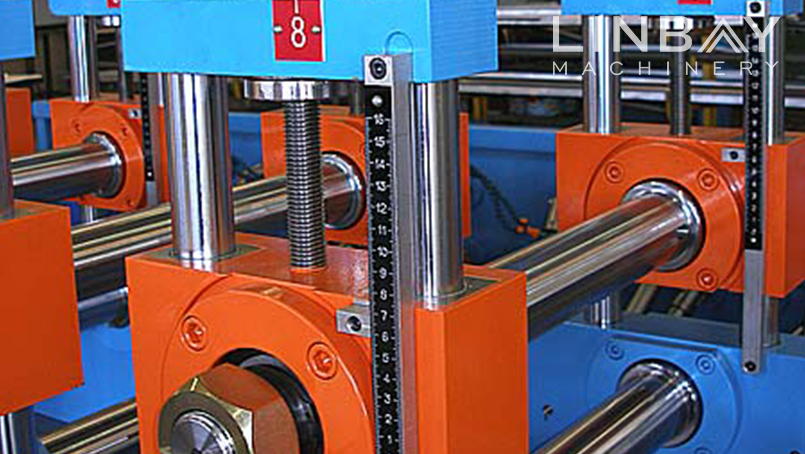

3 |

Forming station |

12-15 |

According to your profile |

|

4 |

Decoiler |

Hydraulic decoiler |

|

|

5 |

Main machine motor |

Sino-German Brand |

Siemens |

|

6 |

PLC brand |

Panasonic |

Siemens |

|

7 |

Inverter brand |

Yaskawa |

|

|

8 |

Driving system |

Gearbox drive |

Chain drive |

|

9 |

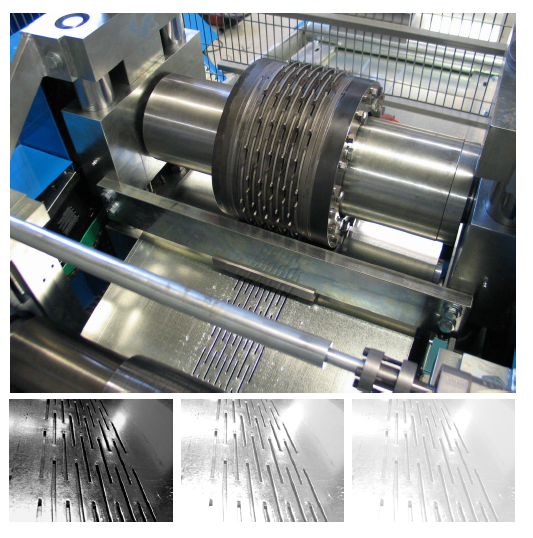

Rollers’ materail |

Cr12 |

GCr15 or #45 Steel |

|

10 |

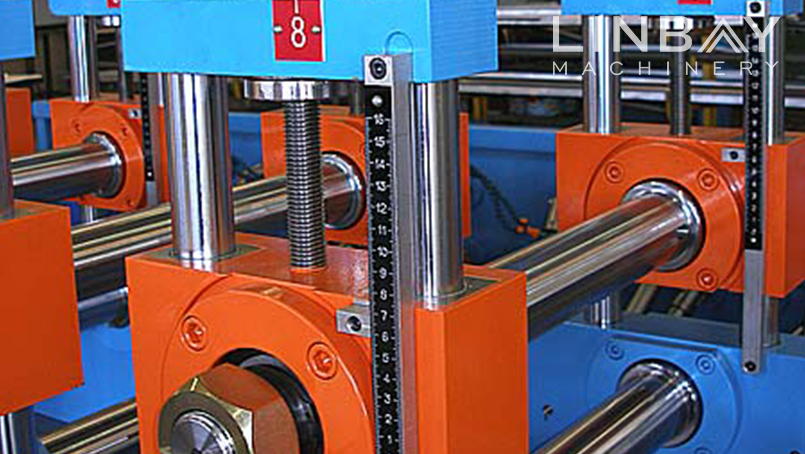

Station structure |

Forged Iron station |

Wall panel station

Or torri stand structure

|

|

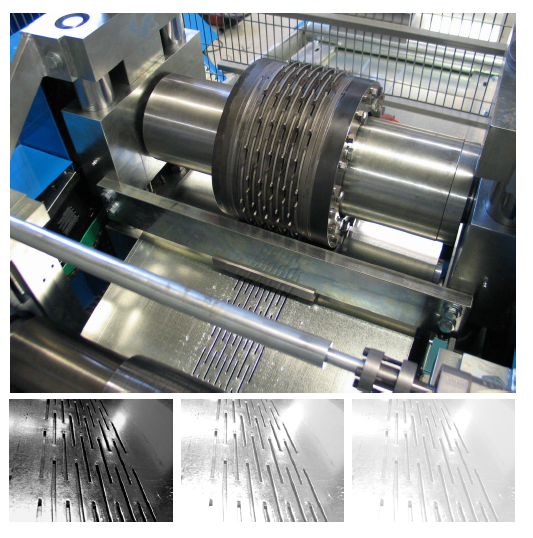

11 |

Punching system |

No |

Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

1. Q: Why buy a Linbay machine?

A: At Linbay we seek to establish long-lasting relationships by offering the best quality and price, as well as unparalleled experience and attention in the market. We have customer service in Mexico and China to solve any questions or inconveniences, backed by our 12 years of experience in the market.

2. Q: What is the delivery time?

A: The lead time is 60 to 80 days, during which we produce, assemble and test to ensure that the machine meets your expectations and required safety standards.

3. Q: How do I get started with my machine?

A: Upon receipt of your machine, an assembly tutorial and operation manual will be provided. We recommend a visit from our technician if this is your first time using a forming machine or if you have doubts about its operation. The technician will explain every detail and train your work team.

4. Q: What process do I need to follow to buy a machine?

A: You can start by contacting our sales team via message or email. Afterwards, we will discuss which type of machine best fits your needs and standards. If you want to know more about our company, you can visit our office in Mexico or our factory in China for a tour and observe our manufacturing process. Once you decide to join the Linbay family, we will start manufacturing your machine after signing the contracts and making a 30% down payment.

Turkish Guardrail profile drawing:

Meet EN 1461:2009 Standard

-

Out table

-

Non-powered

-

Auto stacker

-

-

Cutting

-

flying shear

-

Saw cutting

-

-

Driving

-

chain drive

-

gearbox drive

-

gearbox drive with coupling

-

-

Stands

-

wall panel

-

torri stands

-

forged iron

-

ruler

-

-

Punching

-

punching press

-

hydraulic punching station

-

roller punch

-

-

Feeding

-

Leveler

-

servo feeder

-

-

Decoiler

-

manual decoiler

-

hydraulic decoiler

-

double head decoiler

-