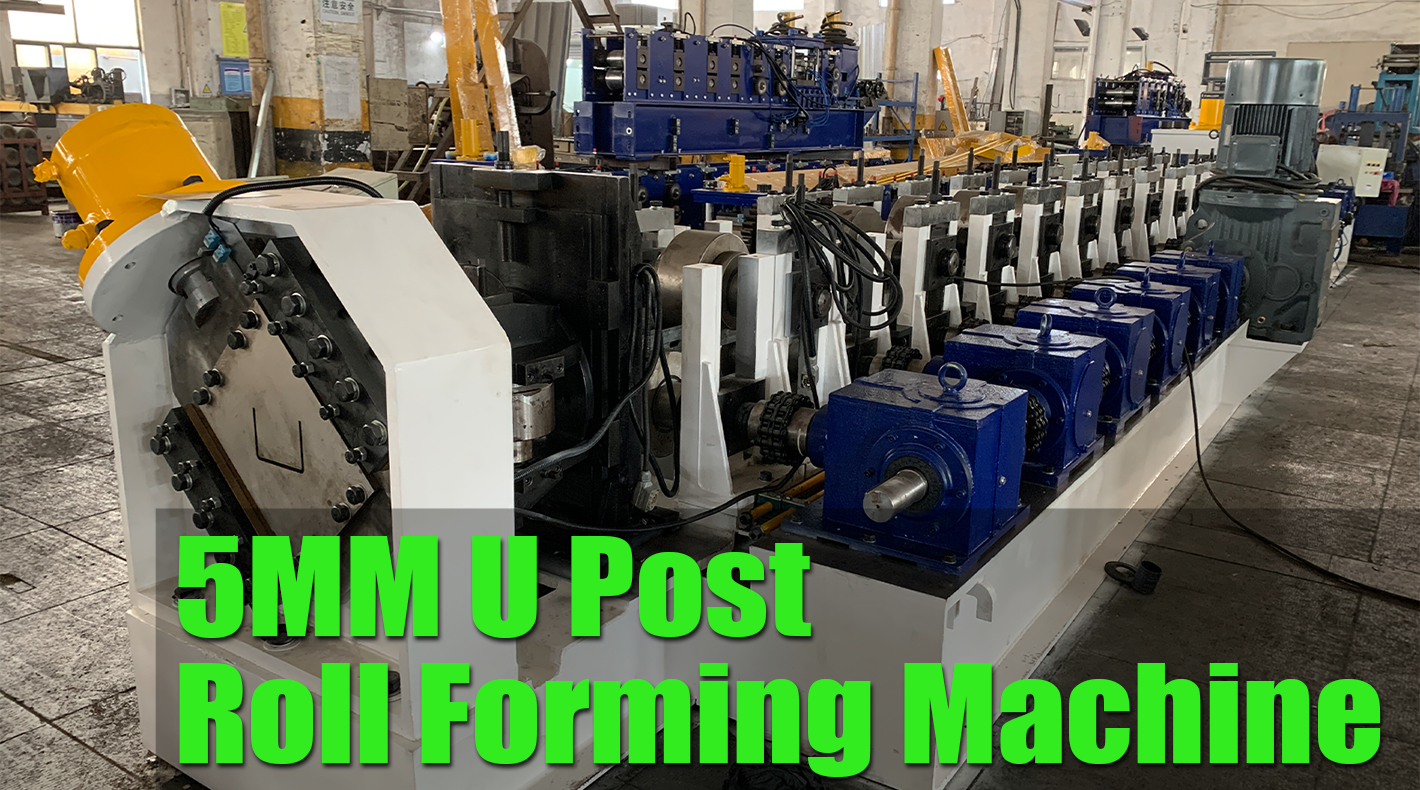

Highway U Post Roll Forming Machine

Linbay offers the forming machine for railroad poles, which has the function of being installed on the ground or a concrete base, and then it can be bolted to the guardrail, if necessary another piece can be used as a connection to have a larger distance between the first pole and the guardrail.

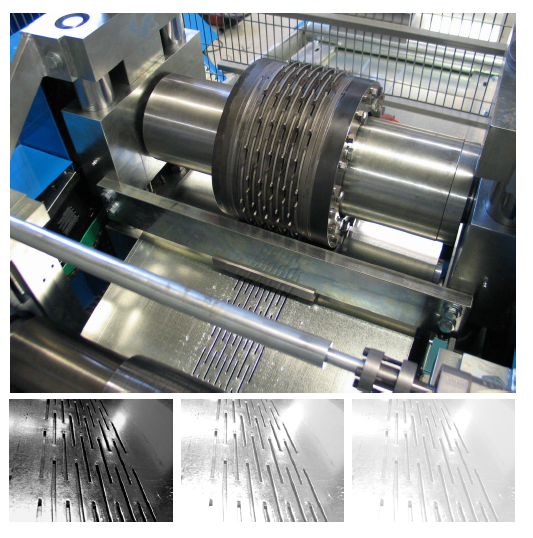

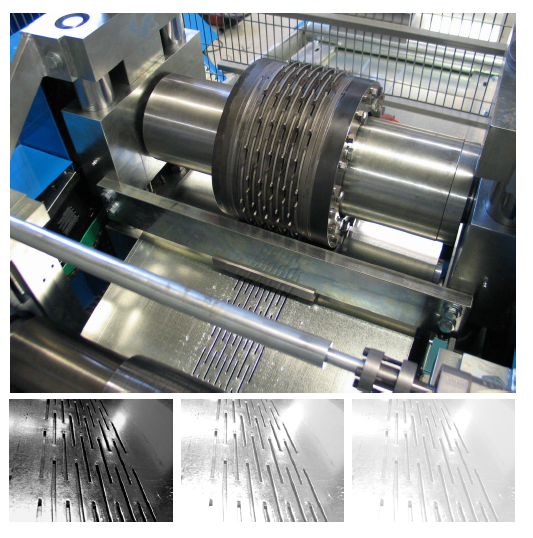

The speed of this line is 6m/min, using an S355JR steel, with a thickness of 5mm, when we use material with this type of thickness it is necessary to use a shovel-type guide system to be able to control the passage more precisely. Using a hydraulic uncoiler with up to a speed of 20m/min, we can use our metal coil without problems, a hydraulic punching system was incorporated into the machine, with a customized design which can be modified, if you look for something faster, you could choose to use a die cutter before entering the former.

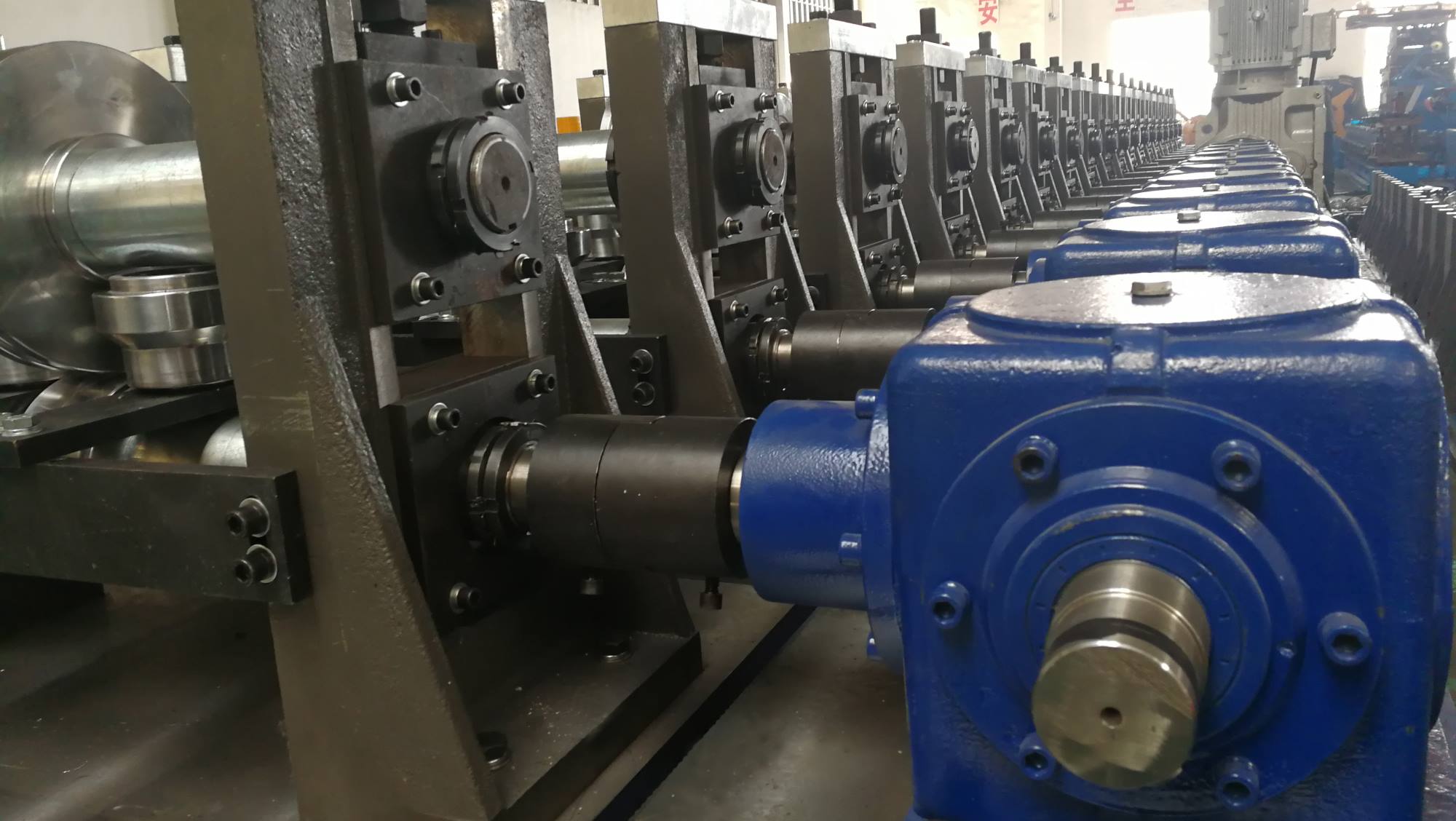

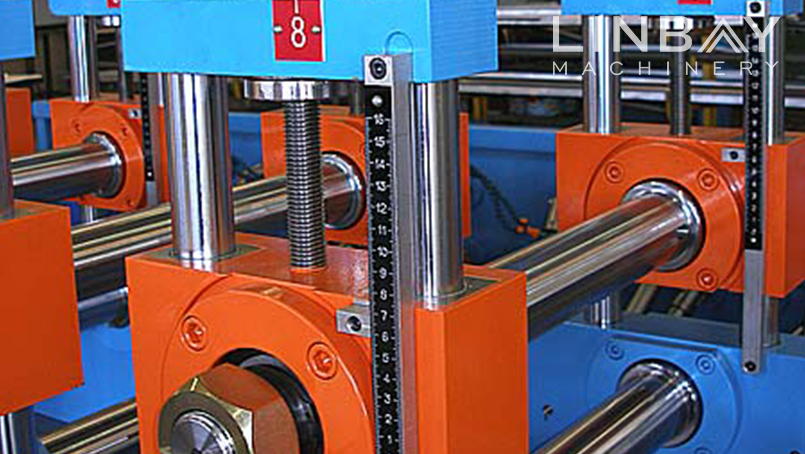

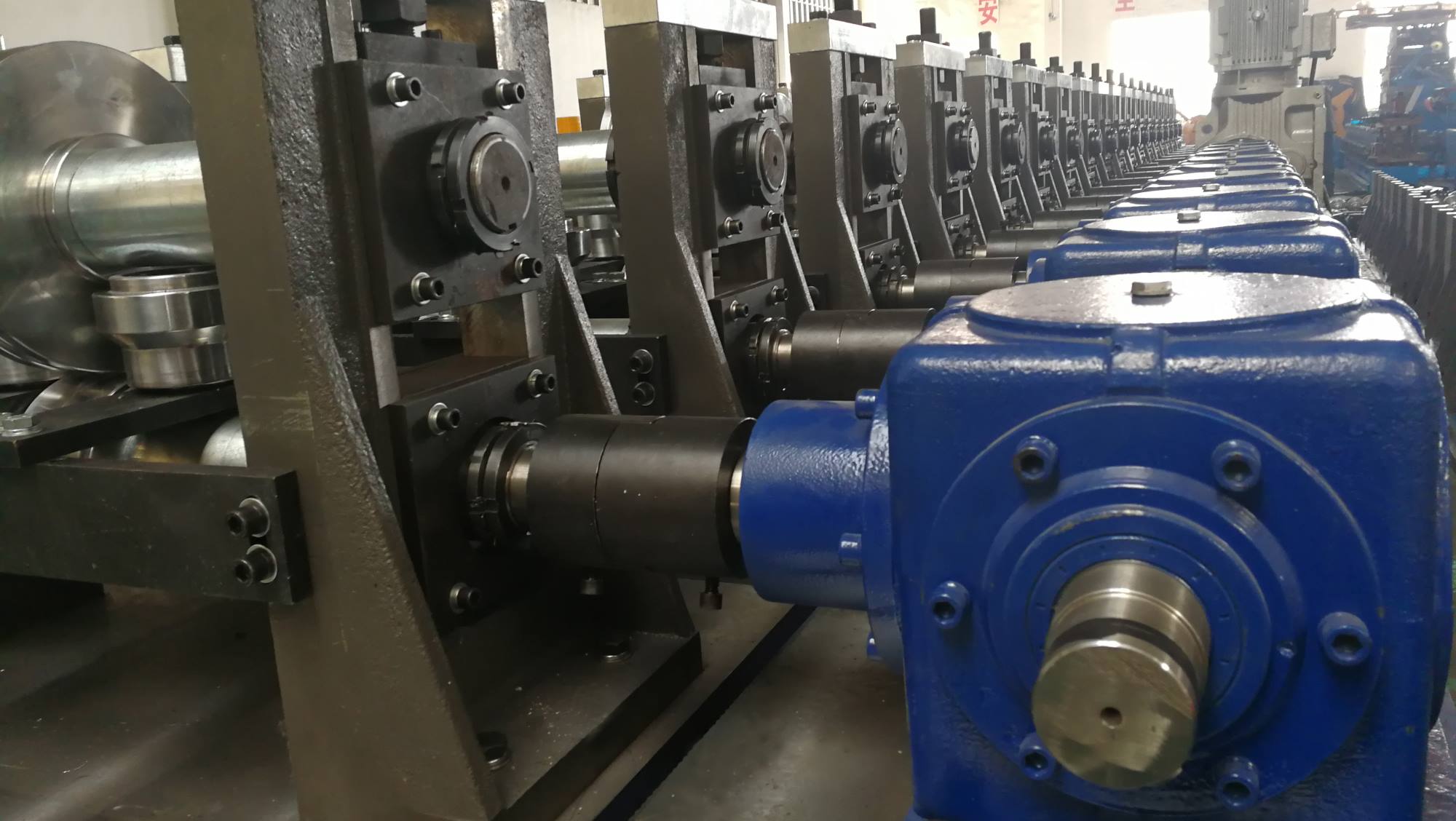

A wrought iron structure is used to have stability when deforming the material, as well as a transmission system with gearboxes, which is the best option when we use a thickness of 5mm. We will obtain 20mm residues in each cut.

Since each pole will be very heavy, for safety reasons it is recommended to use a stacker, which will automatically collect each pole that is produced.

If you are looking to create a design that is different from the current market, our team can help you make it possible by knowing your standards and requirements, thus offering you the different options that are most suitable for your company.

All our operating systems are translated into Spanish and English, as are the operating manuals, so that your work team can operate the machine efficiently and safely.

We had experience of Russian type Guardrail, there are four lines totally:① two wave guardrail roll forming machine, ② U post roll forming machine,③ connection punching line and ④end wind punching line.

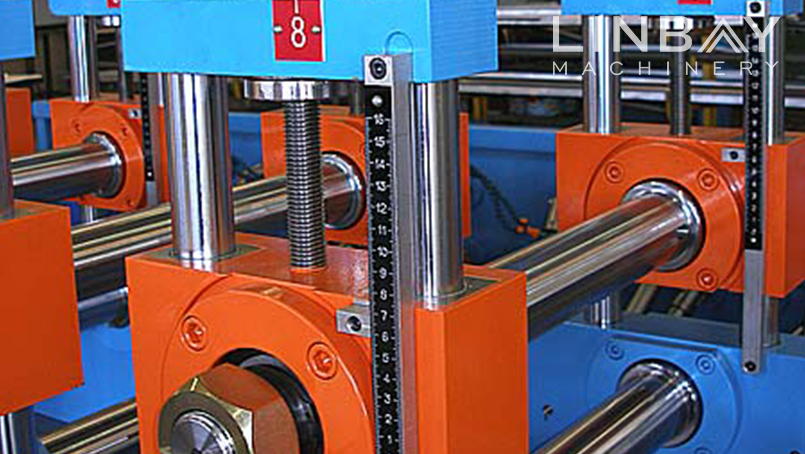

This U Roll Forming Machine can be designed for thickness 4-5mm, it is widely used as post of guardrail. We use forged iron stands(see picture) and gearbox driving to make sure this machine can longly work in a stable situation.

The flow chart of U post roll forming machine:

|

Two Waves/Three Waves Highway Guardrail Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil |

|

|

|

|

Thickness(mm):4-5 |

|

|

|

|

Yield strength: 250 - 550MPa |

|

|

|

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

|

|

2 |

Nominal forming speed(m/min) |

15 |

Or according to your requirement |

|

3 |

Forming station |

10-12 |

According to your profile |

|

4 |

Decoiler |

Hydraulic decoiler |

|

|

5 |

Main machine motor |

Sino-German Brand |

Siemens |

|

6 |

PLC brand |

Siemens |

Panasonic |

|

7 |

Inverter brand |

Yaskawa |

|

|

8 |

Driving system |

Gearbox drive |

Chain drive |

|

9 |

Rollers’ materail |

Cr12 |

GCr15 or #45 Steel |

|

10 |

Station structure |

Forged Iron station |

Wall panel station

Or torri stand structure

|

|

11 |

Punching system |

No |

Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

1. Q: Why buy a Linbay machine?

A: At Linbay we seek to establish long-lasting relationships by offering the best quality and price, as well as unparalleled experience and attention in the market. We have customer service in Mexico and China to solve any questions or inconveniences, backed by our 12 years of experience in the market.

2. Q: What is the delivery time?

A: The lead time is 60 to 80 days, during which we produce, assemble and test to ensure that the machine meets your expectations and required safety standards.

3. Q: How do I get started with my machine?

A: Upon receipt of your machine, an assembly tutorial and operation manual will be provided. We recommend a visit from our technician if this is your first time using a forming machine or if you have doubts about its operation. The technician will explain every detail and train your work team.

4. Q: What process do I need to follow to buy a machine?

A: You can start by contacting our sales team via message or email. Afterwards, we will discuss which type of machine best fits your needs and standards. If you want to know more about our company, you can visit our office in Mexico or our factory in China for a tour and observe our manufacturing process. Once you decide to join the Linbay family, we will start manufacturing your machine after signing the contracts and making a 30% down payment.

-

Out table

-

Non-powered

-

Auto stacker

-

-

Cutting

-

flying shear

-

Saw cutting

-

-

Driving

-

chain drive

-

gearbox drive

-

gearbox drive with coupling

-

-

Stands

-

wall panel

-

torri stands

-

forged iron

-

ruler

-

-

Punching

-

punching press

-

hydraulic punching station

-

roller punch

-

-

Feeding

-

Leveler

-

servo feeder

-

-

Decoiler

-

manual decoiler

-

hydraulic decoiler

-

double head decoiler

-