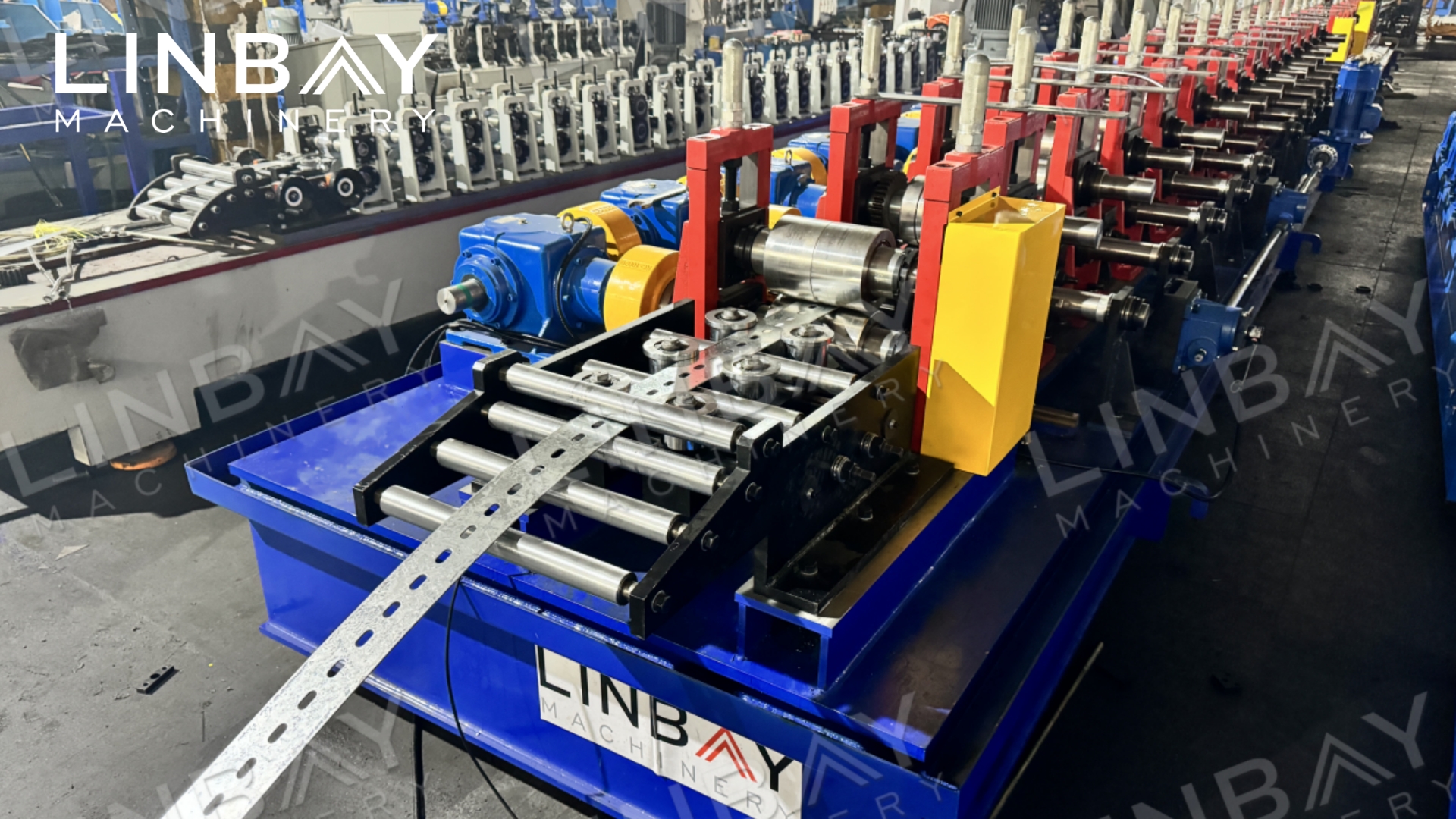

Flying Saw Cutting Strut Channel Roll Forming Machine

Linbay offers the strut channel forming machine, this profile is used for the transport of cargo in industrial and commercial environments, it can also be found in the installation of lighting systems, support of trays for cables and pipes.

The machine has a speed from 10m/min to 25m/min, with the option of using the machine up to 40m/min by combining the forming machine with a die-cutter that can reach up to 50m/min. All depending on your needs we will be able to provide you with the best option. On this machine we can produce up to 5 different sizes (41mm x 21mm, 41mm x 41mm, 41mm x 62mm or 27mm x 18mm, 27mm x 30mm). On the other hand, the configuration of (4 ̈X4 ̈, 4 ̈X2 ̈) can also be produced, being one of the most used profiles currently in Mexico, USA, Peru, Pakistan and Argentina. In order to be able to produce the different sizes in the same machine we can provide you with different options:

1-Self-regulating change, with the help of a servo motor we can change the opening of the rollers, this process being practical, safe and precise. This process can be done from the screen of our electrical cabinet, making the measurement change in less than a minute.

2-You can choose to make a manual change, which consists of changing the spacers between the rollers of the upper and lower part of the former, thus changing the dimensions of our profile.

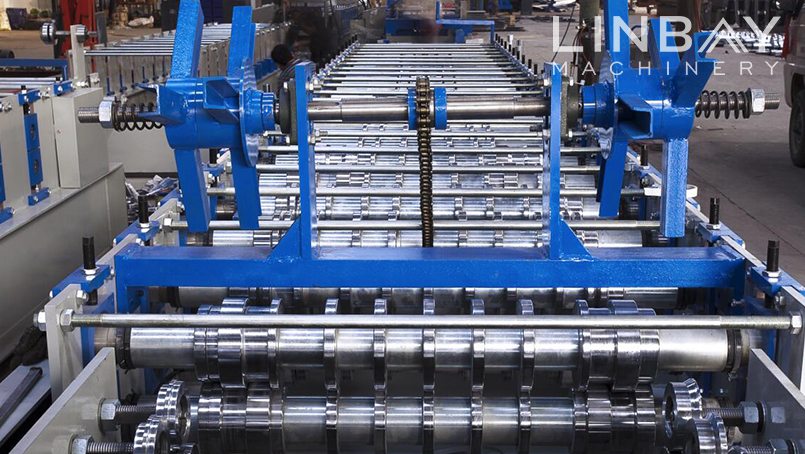

3-If you are looking to only work with two sizes 4 ̈X4 ̈, 4 ̈X2, you can offer the configuration of having 2 lines on the same machine, in which only one line can be operated at a time, but it is no longer necessary to make any changes within the former.

For this profile you can work with galvanized steel, PPGI and carbon steel with a thickness from 1.5mm to 2.5mm (Gauge 12 to 16), this can be modified to your needs.

If you are looking to create a design that is different from the current market, our team can help you make it possible by knowing your standards and requirements, thus offering you the different options that are most suitable for your company.

All our operating systems are translated into Spanish and English, as are the operating manuals, so that your work team can operate the machine efficiently and safely.

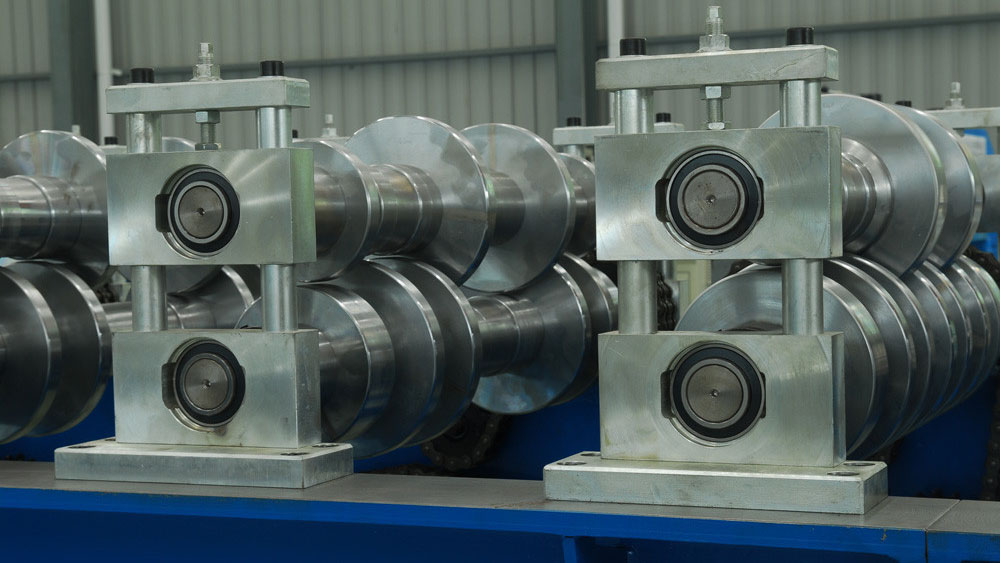

Strut channels are commonly used for solar panel mounting, plumbing and piping, HVAC systems, and more. The common heights of strut channel are 21/41/52/62/71/82mm. The diameter of forming rollers varies depending on the strut channel’s height, and the higher the height, the more forming stations there are. They are usually made from hot-rolled steel, cold-rolled steel, galvanized steel, and stainless steel, with thicknesses ranging from 12 gauge (2.5mm) to 16 gauge (1.5mm).

Note: The forming force required for stainless steel is greater than that for low-alloy steel and regular carbon steel of the same thickness due to the higher yield strength of stainless steel. So, the roll forming machine used for stainless steel raw materials differs from that used for regular carbon steel and galvanized steel.

LINBAY offers production lines that produce multiple dimensions, categorized into manual and automated types based on the automation level for dimension changes.

Flow chart: Decoiler--Servo feeder--Punch press--Guiding--Roll forming machine--Flying saw cutting--Out table

Real case-Main Technical Parameters

1.Line speed: 15m/min, adjustable

2.Suitable material:Hot rolled steel, cold rolled steel, galvanized steel

3.Material thickness: 1.5-2.5mm

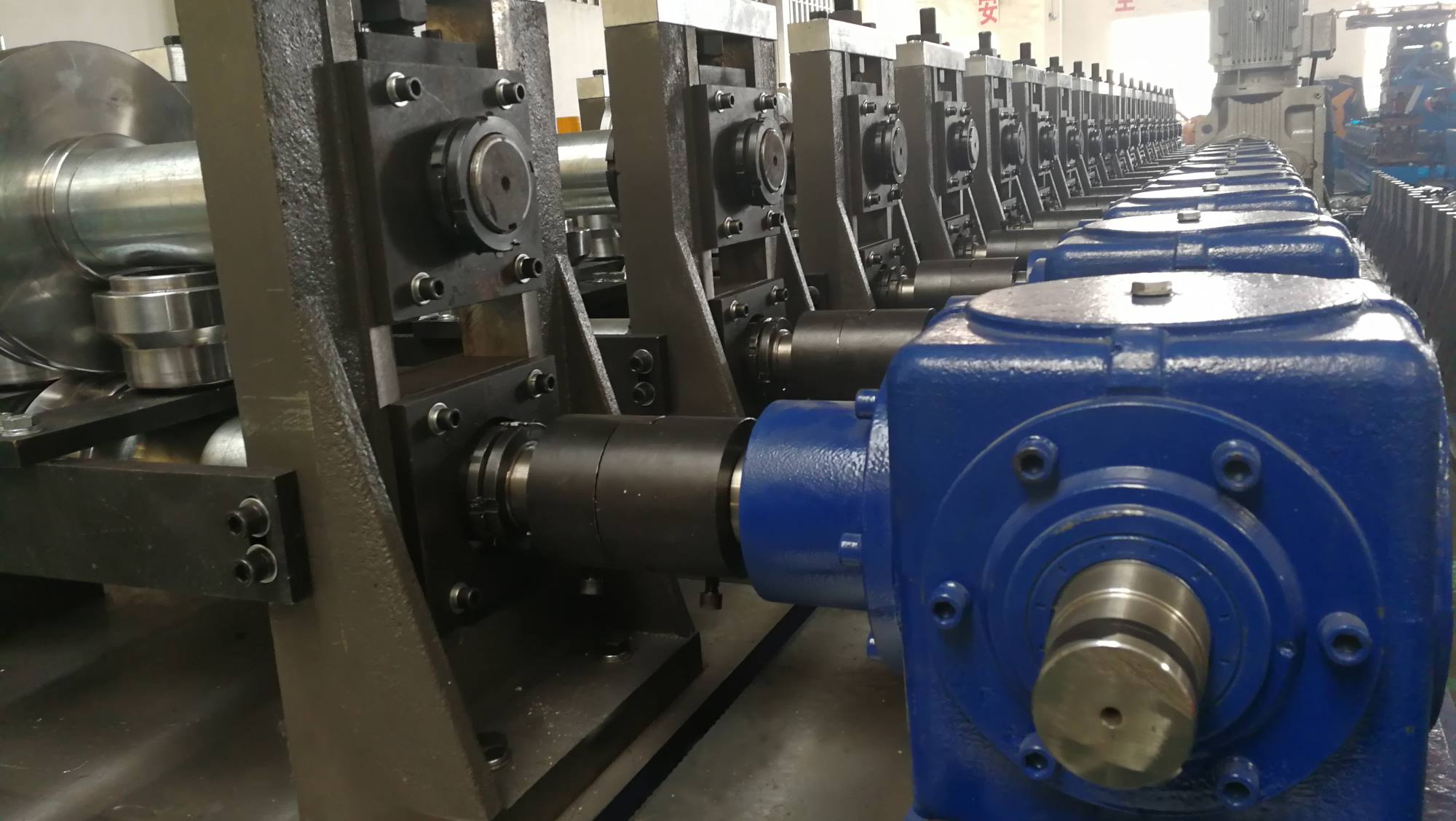

4.Roll forming machine: Cast-iron structure

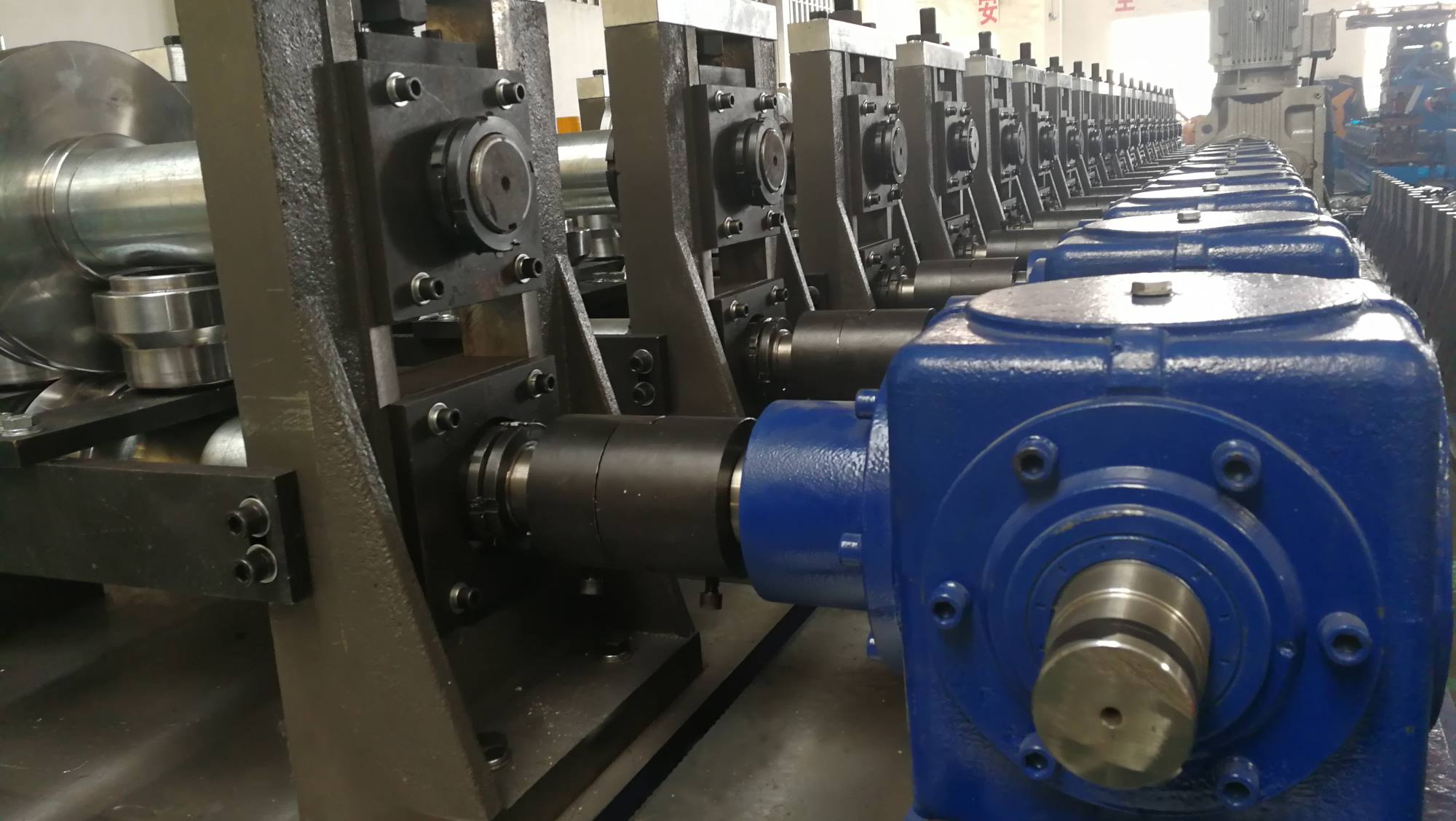

5.Driving system: Gearbox driving system

6.Cutting system: Flying saw cutting. Roll forming machine doesn’t stop when cutting

7.PLC cabinet: Siemens system

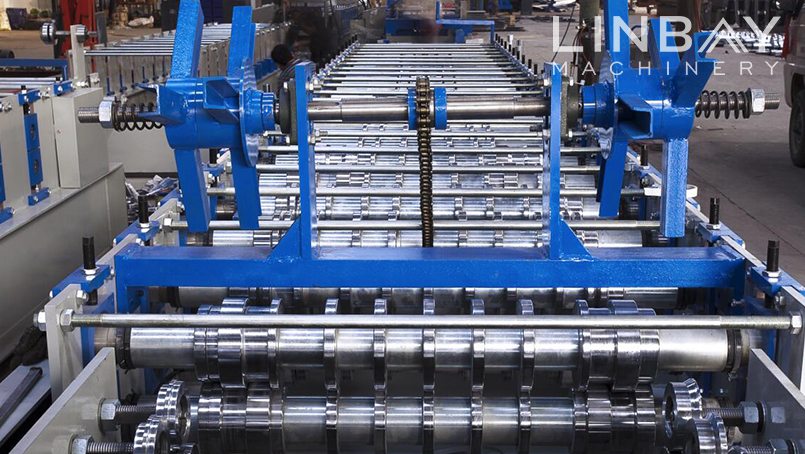

Real case-Machinery

1.Hydraulic decoiler with leveler*1

2.Servo feeder*1

3.Punch press*1

4.Roll forming machine*1

5.Flying saw cutting machine*1

6.PLC control cabinet*2

7.Hydraulic station*2

8.Spare parts box(Free)*1

Container size: 2x40GP+1x20GP

Real case-Description

Decoiler with Leveler (2 in 1)

This machine combines the functions of a decoiler and a leveler, saving floor space cost. It is essential to level steel coils thicker than 1.5mm, especially for continuous holes punching of strut channels. The leveler smooths the steel coil and releases internal stress, making it easier to shape and form straight.

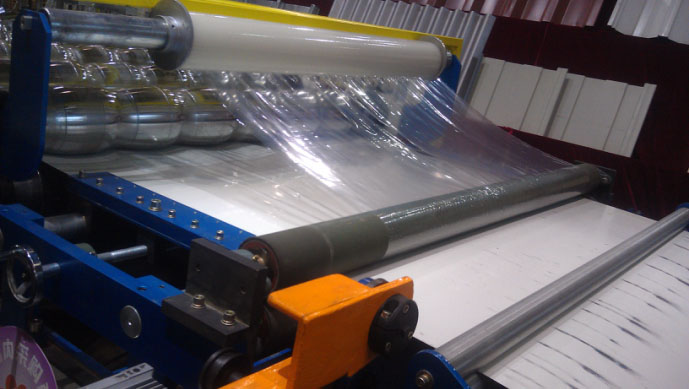

Servo Feeder

A servo feeder gets the name cause it’s powered by a servo motor. Due to the servo motor's minimal start-stop delay, it provides exceptional accuracy in steel coil feeding. This accuracy is crucial for maintaining tight tolerances and reducing steel coil waste when producing strut channels. Additionally, pneumatic clamps inside the feeder advance the steel coil while protecting its surface from scratches.

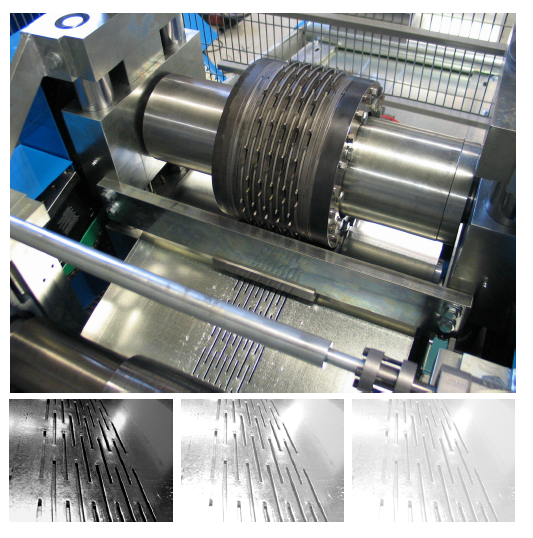

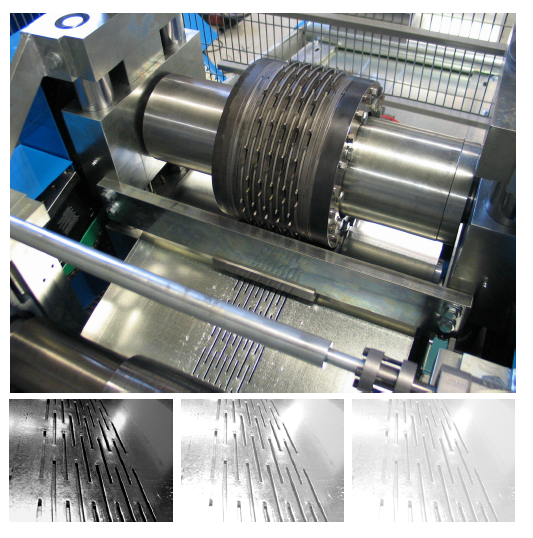

Punch Press

A punch press is used to punch holes in the steel coil, which are necessary for installing screws and nuts to secure the strut channels. The punch press operates faster than an integrated hydraulic punch (on the same base as the roll forming machine) and a standalone hydraulic punch. We use punch presses from the renowned Chinese brand Yangli, which has multiple offices worldwide, making after-sales service and purchasing replacement parts convenient.

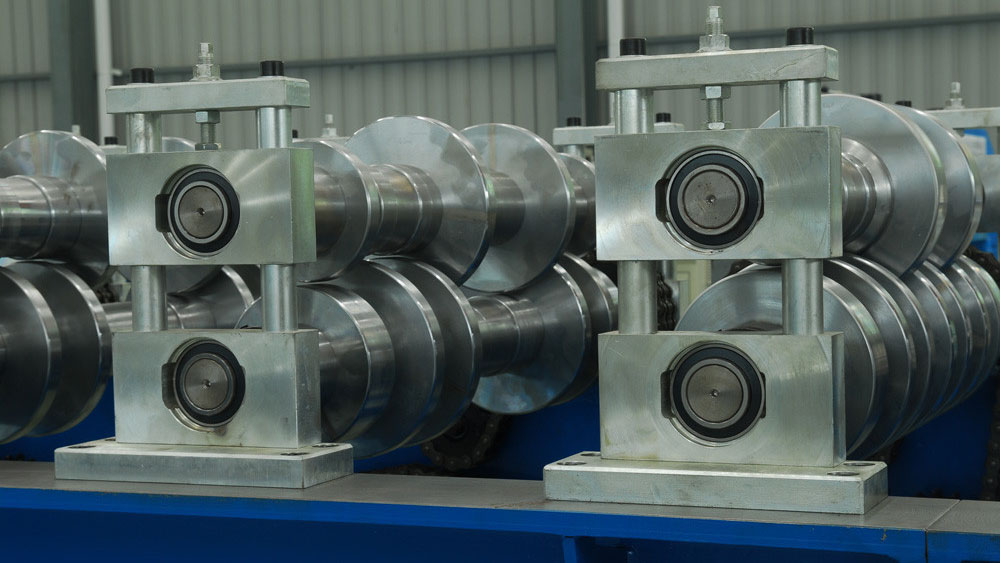

Guiding

Guide rollers ensure that the steel coil and machines stay aligned along the same centerline, maintaining the strut channel's straightness. This helps the strut channels match with other profiles during installation, directly affecting the stability of the entire construction structure.

Roll Forming Machine

The roll forming machine features a cast-iron structure, made from the single piece of steel, ensuring exceptional durability. The upper and lower rollers apply force to shape the steel coil, driven by a gearbox to ensure adequate power for forming.

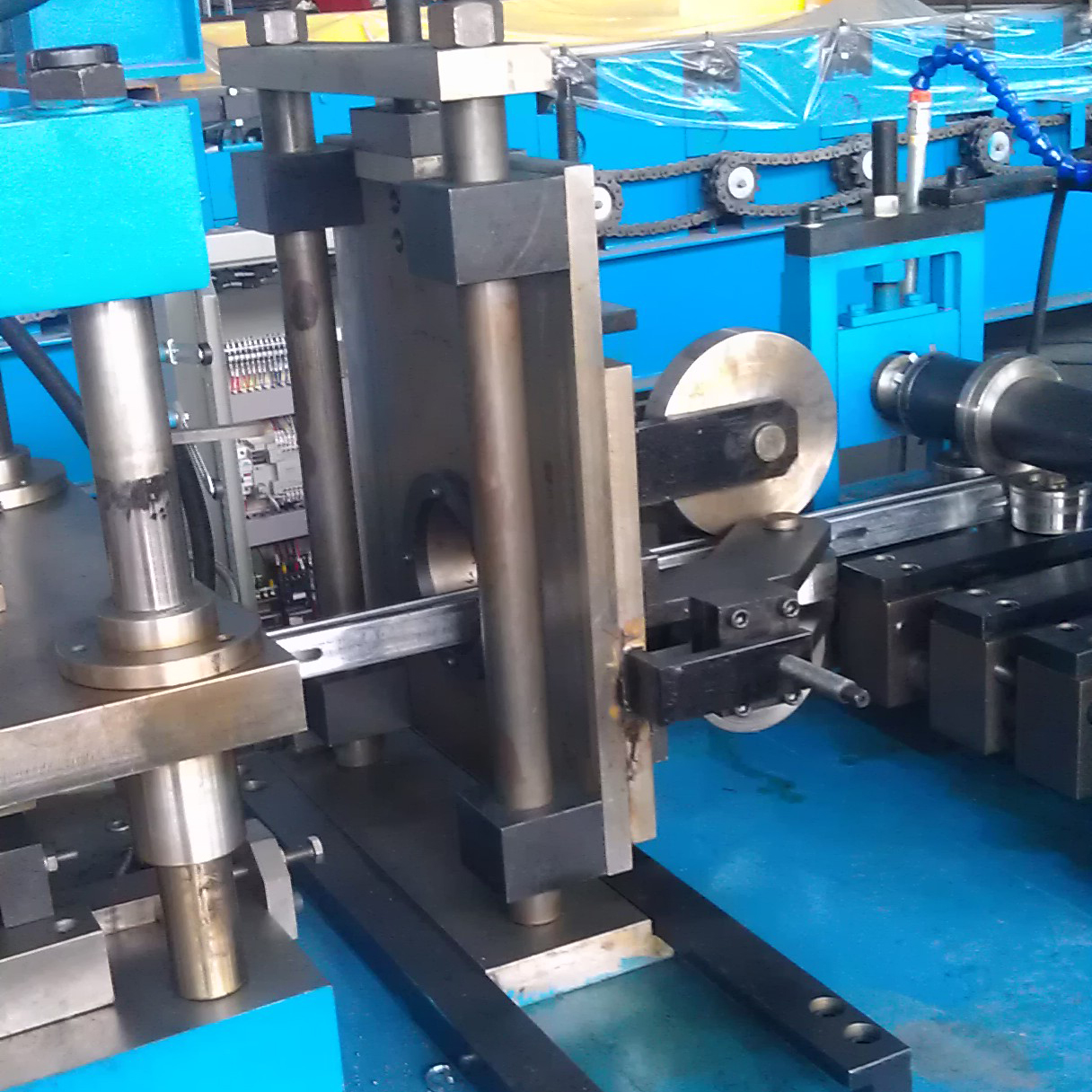

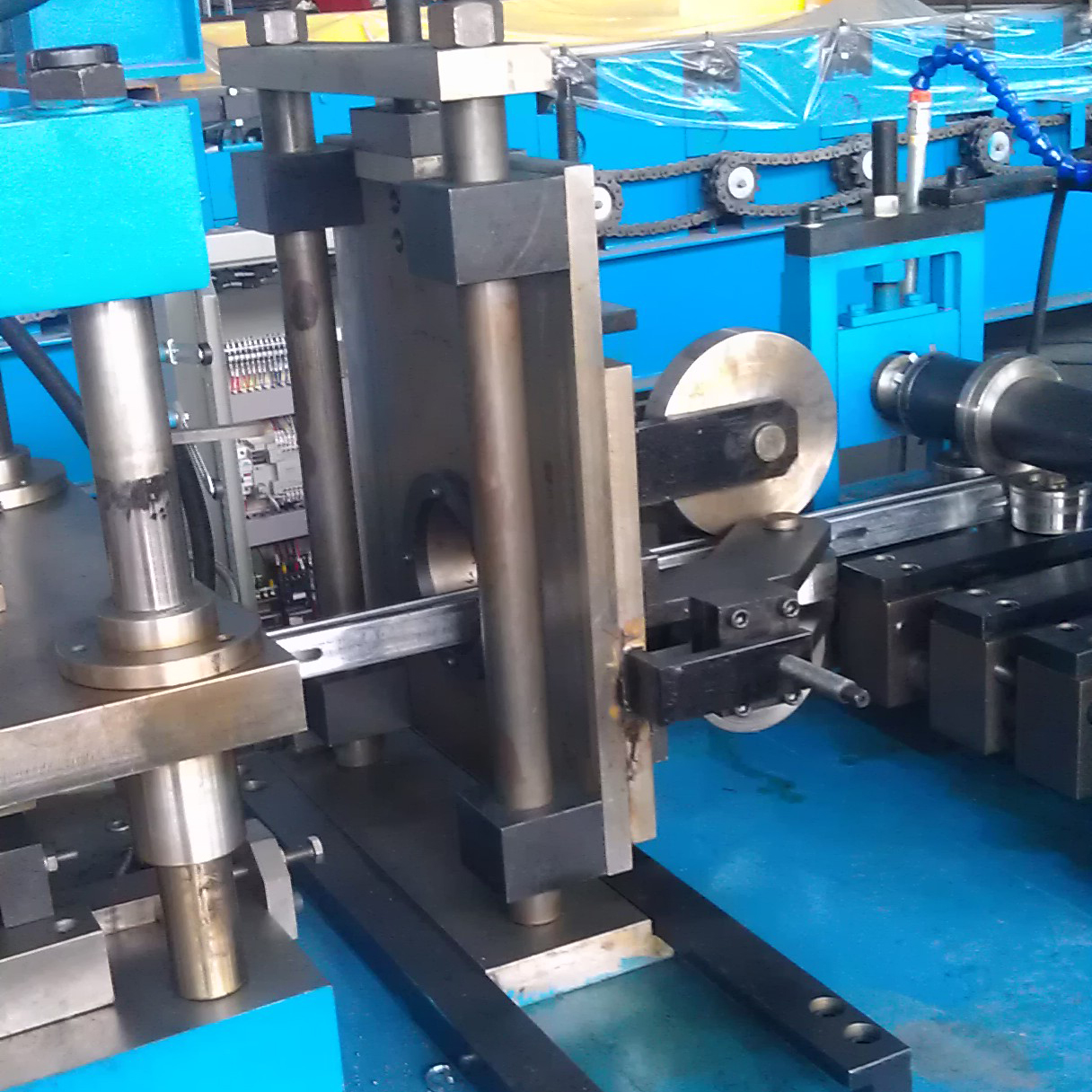

Flying Saw Cutting

The flying saw cutter's carriage accelerates to match the speed of the moving strut channels (also the speed of the roll forming machine), allowing for cutting without stopping the production process. This highly efficient cutting solution is ideal for high-speed operations and produces virtually no waste.

During cutting, the saw blade base moves toward the strut channel using pneumatic power, while hydraulic power from the hydraulic station drives the rotation of the saw blade.

Hydraulic Station

The hydraulic station provides the necessary power to operate equipment such as the hydraulic decoiler and hydraulic cutter, and equipped with cooling fans for efficient heat dissipation.

For hot climates, we recommend increasing the hydraulic reservoir size to enhance heat dissipation and provide a larger volume of fluid for heat absorption. These methods help maintain a stable operating temperature during extended operation, ensuring the roll forming production line's reliability and efficiency.

PLC Control Cabinet & Encoder

Encoders are essential for providing feedback on position, speed, and synchronization. They convert the measured length of the steel coil into electrical signals sent to the PLC control cabinet. The control cabinet display allows operators to manage production speed, output quantity per cycle, cutting length, and more. With accurate measurement and feedback from encoders, the cutting machine can maintain a cutting error within ±1mm.

Flying hydraulic cutting VS Flying saw cutting

The cutting blade: The flying hydraulic cutter requires one standalone cutting blade for each dimension. However, saw cutting isn’t limited by the dimension of strut channels.

Wear and Tear: Saw blades wear out faster than hydraulic cutting blades and need more frequent replacement.

Noise: Saw cutting can be noisier compared to hydraulic cutting, potentially requiring more soundproofing in the production area.

Waste: Even when calibrated, a hydraulic cutter generates an unavoidable 8-10mm of waste with each cut. In contrast, a saw cutter produces almost no waste.

Maintenance: Saw blades need a coolant system to reduce heat from friction for continuous, efficient cutting. Hydraulic cutting maintains a more stable temperature.

Material limitation: Stainless steel has a higher yield strength compared to regular carbon steel. When using stainless steel as the raw material, only the saw cut is required for cutting.

1. Q: Why buy a Linbay machine?

A: At Linbay we seek to establish long-lasting relationships by offering the best quality and price, as well as unparalleled experience and attention in the market. We have customer service in Mexico and China to solve any questions or inconveniences, backed by our 12 years of experience in the market.

2. Q: What is the delivery time?

A: The lead time is 60 to 80 days, during which we produce, assemble and test to ensure that the machine meets your expectations and required safety standards.

3. Q: How do I get started with my machine?

A: Upon receipt of your machine, an assembly tutorial and operation manual will be provided. We recommend a visit from our technician if this is your first time using a forming machine or if you have doubts about its operation. The technician will explain every detail and train your work team.

4. Q: What process do I need to follow to buy a machine?

A: You can start by contacting our sales team via message or email. Afterwards, we will discuss which type of machine best fits your needs and standards. If you want to know more about our company, you can visit our office in Mexico or our factory in China for a tour and observe our manufacturing process. Once you decide to join the Linbay family, we will start manufacturing your machine after signing the contracts and making a 30% down payment.

5. Q: What determines the speed of the forming machine?

A: The speed depends on the requirements of your profile, as well as the structure of the machine you can choose between panel, forged steel and Torri which gives us greater stability. If the gearbox-type transmission system is chosen, we will improve its performance and increase the speed of the system. If your profile must be perforated, the best option is to use a die-cutter, with which our speed can be higher. Finally, choose what type of cut we want, fixed hydraulic cut or hydraulic cut with movable base in which the base will move with the material, cutting precisely and without reducing speed.

American standard profiles:

-

Others

-

scrap collector

-

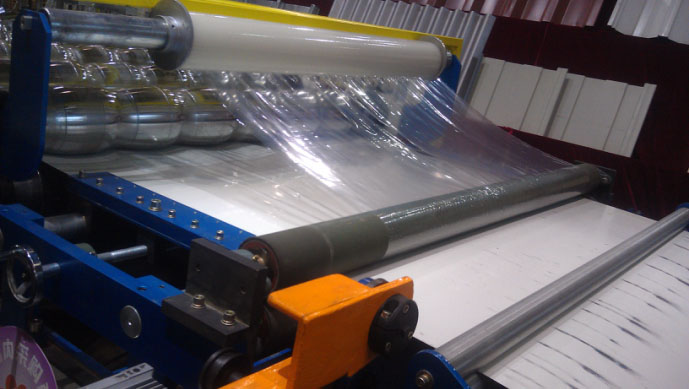

pasting

-

mould change

-

guiding head

-

Cooling system

-

-

Out table

-

non-powered

-

auto stacker

-

-

Cutting

-

saw cutting

-

flying shear

-

-

Driving

-

chain drive

-

gearbox drive

-

gearbox drive with coupling

-

-

Stands

-

wall panel stands

-

torri stands

-

forged iron stands

-

wall panel for Cpurlin

-

-

Punching

-

hydraulic punching station

-

punching press

-

roller punching

-

-

Feeding

-

leveling

-

servo feeding

-

-

Decoiler

-

manual decoiler

-

hydraulic decoiler

-

double head decoiler

-