.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

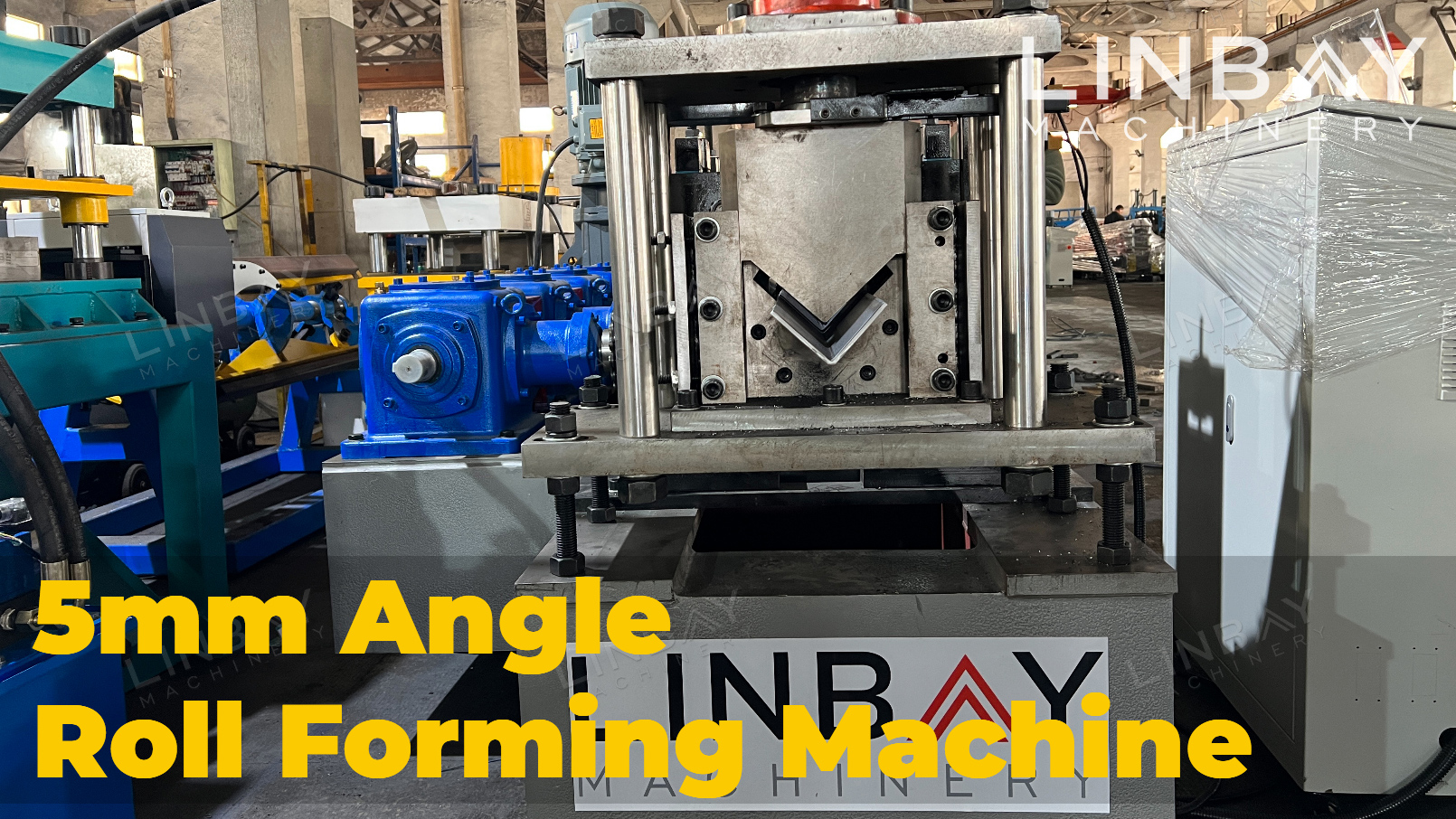

5mm Slotted Angle Roll Forming Machine

The shape of steel angle is relatively simple, typically available in equal and L-shaped configurations. Generally, steel angle is made of galvanized steel and cold rolled steel, with thickness range from 3.0mm to 5.0 mm. In this introduction, we are focusing on a classic and regularly used 5mm thick angle steel production machinery without perforations.

Linbay offers the forming machine for slotted angles up to 5 mm, known for its simple L-shaped design, which is used in racking systems. For this particular design, it was necessary to use a cast-iron structure, which allows working with a thickness of up to 5 mm. It is vital to use a gearbox to be able to move the material inside the forming machine more easily. Finally, a hydraulic-type cutting system is used.

Material such as galvanized or cold roll can be used, with a thickness from 3 mm to 5 mm.

If you are looking to create a design that is different from the current market, our team can help you make it possible by knowing your standards and requirements, thus offering you the different options that are most suitable for your company.

All our operating systems are translated into Spanish and English, as are the operating manuals, so that your work team can operate the machine efficiently and safely.

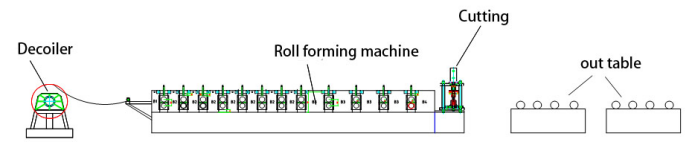

Flow chart

Decoiler-Roll former-Hydraulic cut-Out table

Decoiler-Roll former-Hydraulic cut-Out table

Decoiler

The 3-ton manual decoiler doesn’t have its own power source. Instead, it relies on the power supplied by the roll forming machine to unwind and lead the steel coil. Depending on the customer's budget and specific requirements, we also offer a high-end option, the hydraulic decoiler. The hydraulic decoiler is powered by a hydraulic station, enabling more efficient and rapid coil unwinding.

We will configure a press-arm, which will press the steel coil when changing the steel coil to prevent the coil from springing up and injuring the workers.

Roll forming machine

This roll forming machine is capable of producing angle profiles with a thickness of 5mm. We have equipped it with a robust cast-iron structure, composed of a whole solid piece of iron, ensuring both durability and stability. Each forming station is fitted with a gearbox, providing powerful rotational force to achieve the 5mm steel angle forming capability. Additionally, the large diameter and dimensions of the forming rollers are designed to enhance the quality of the formed angles.

Hydraulic cut

The hydraulic cutting has to stop to cut and its cutting power comes from the hydraulic station. Our cutting machine can make the cut products burr-free and the cuts neat. Through PLC and encoders, precise cutting of any length can be achieved, with the error controlled within 0.5mm. As you can see from the picture, the cutting base and roll former are connected together and cannot be moved. We also have a cutting solution called the flying hydraulic cutter. The difference is that it doesn’t stop during cutting and can increase the speed of the entire production line. But which solution to choose depends on the customer's production needs.

Hydraulic station

Our hydraulic station is equipped with a cooling fan, which can help cool down the continuously working hydraulic station to improve work efficiency.

Linbay Machinery team will gradually share more steel angle roll forming line configurations. If you have any questions, please feel free to leave a message and contact us.

| Bracing Roll Forming Machine | ||

| Machinable Material : | A) Zinc-plated steel | Thickness(MM): 0.9-2 |

| B) Hot rolled steel | ||

| C) Cold rolled steel | ||

| Yield strength : | 200 - 350 Mpa | |

| Tensil stress : | G200 Mpa-G350 Mpa | |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Punching system : | Hydraulic punch station | |

| Forming station : | 14 stands | * According to your profile drawings |

| Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Wall panel station | * Cast Iron (Optional) |

| Forming speed : | 10-15 (M/MIN) | |

| Rollers’ material : | Steel #45, chromed | * GCr 15 (Optional) |

| Cutting system : | Post-cutting | * Pre-cutting (Optional) |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz 3ph | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

1. Q: Why buy a Linbay machine?

A: Because at Linbay we seek to create relationships that last for years, that is why we offer you the best quality and price, as well as experience and attention unmatched in the market. We have service in Mexico and China, and we will take care of any questions or inconveniences you may have. In addition, our 12 years in the market support us.

2. Q: What is the delivery time?

A: From 60 to 80 days, after producing and assembling the different components. According to your requirements, we must perform different tests to make your machine what you are expecting and meet the required safety standards.

3. Q: How do I get started with my machine?

A: Upon the arrival of your machine, you will be given a tutorial on how to assemble it and a manual to learn how to operate it. If this is the first time you buy a forming machine or you have doubts about its operation, it is recommended to visit our technician, who will be in charge of explaining every detail of the machine, as well as training your work team in its operation.

4. Q: I want to buy a machine, but I don't know how to get started? What process should I follow?

A: You can start by sending a message or email to our sales team. You can then tell us what type of machine you are looking for and which one best meets your standards. If you want to continue with the process, but have questions about our company, you can visit our office in Mexico or go to our factory in China, where you can take a tour of our facilities and learn about each manufacturing process for your machine. If you decide to join the Linbay Family, we will start crafting the machine after signing the contracts and making the 30% down payment.

-

Out table

-

Non-powered

-

Auto-stacker

-

-

Cutting

-

Saw cutting

-

fast flyting cutting

-

-

Driving

-

chain driving system

-

gearbox driving system

-

Gearbox with couplings

-

-

Stands

-

Torri Stands

-

Forged Iron Stands

-

Wall Panel

-

ruler

-

-

Punching

-

Hydraulic punching station

-

Fast Roller Punching system

-

Punching press

-

-

Feeding

-

Servo feeder

-

Leveler

-

-

Decoiler

-

Motorized&Hydraulic decoiler

-

Double head motorized decoiler

-

Manual Decoiler

-

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg)