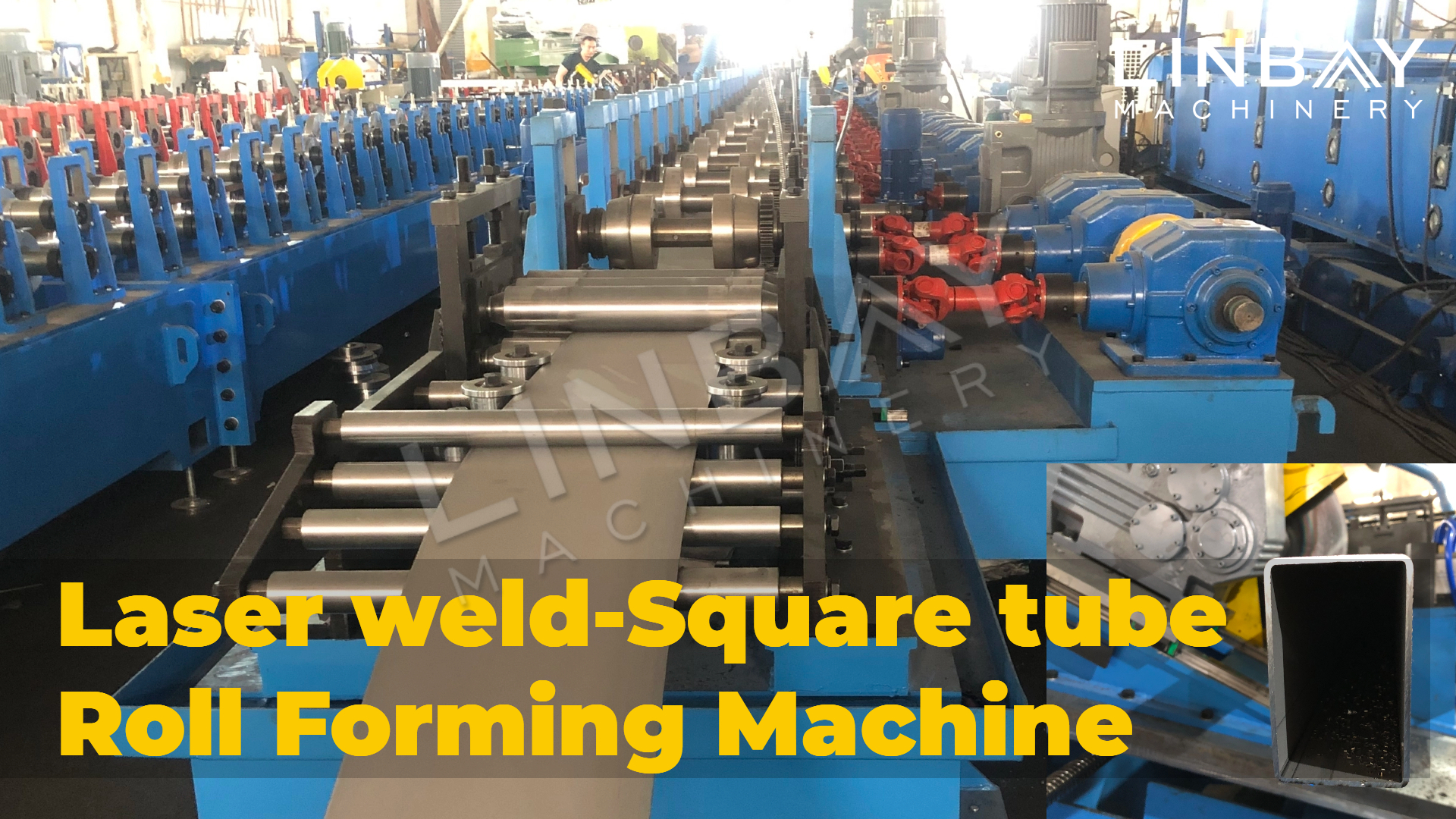

Full automatic laser-weld 2mm square tube roll foming machine

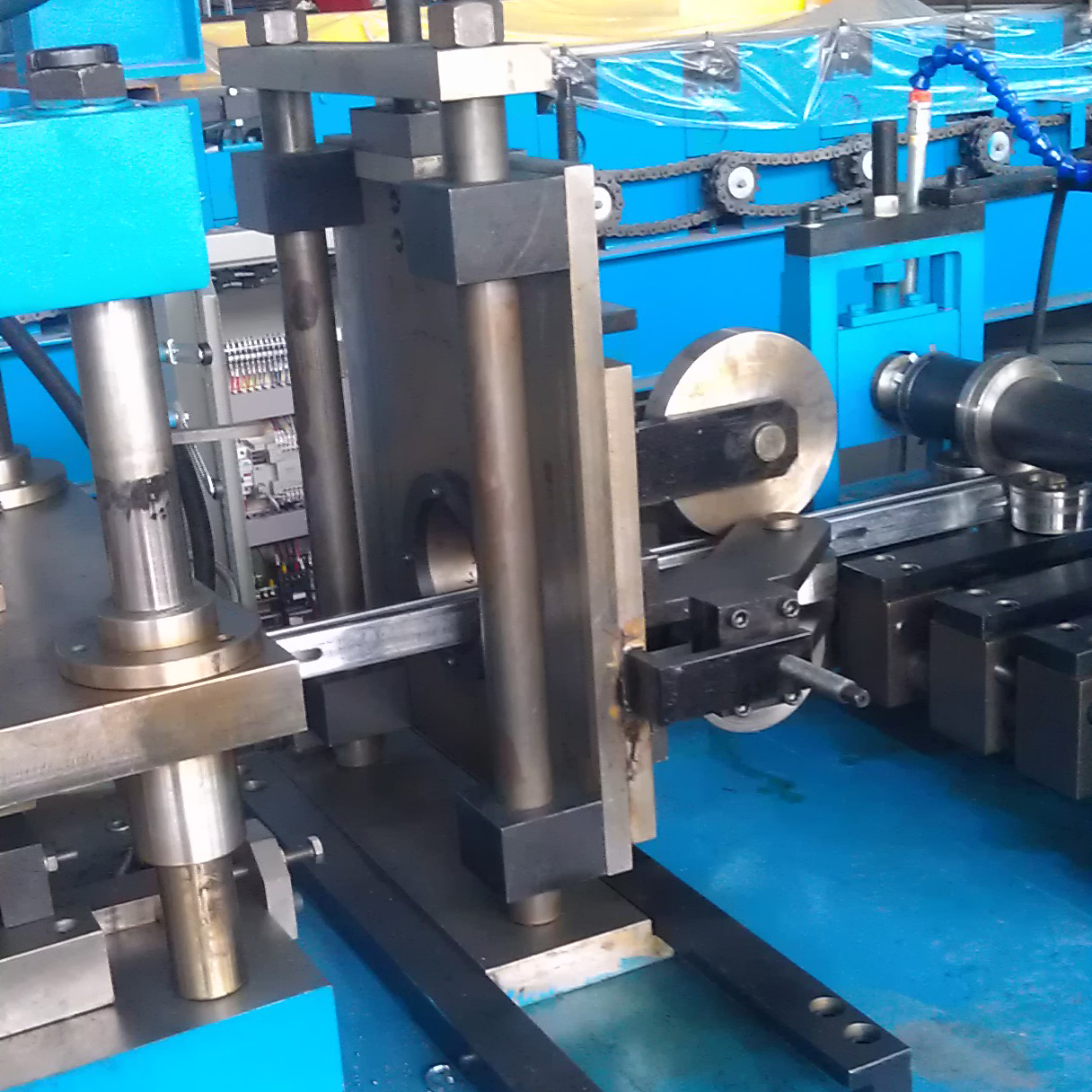

Linbay offers a 2mm square tube forming machine, specially designed for a customer. The machine reaches a speed of 5 to 6 m/min and is available in a variety of sizes, with a width of 50-100 mm and a height of 100 to 200 mm. These adjustments are possible thanks to the self-regulating base which works with a servo motor that opens and closes the base from the screen of our electrical cabinet.

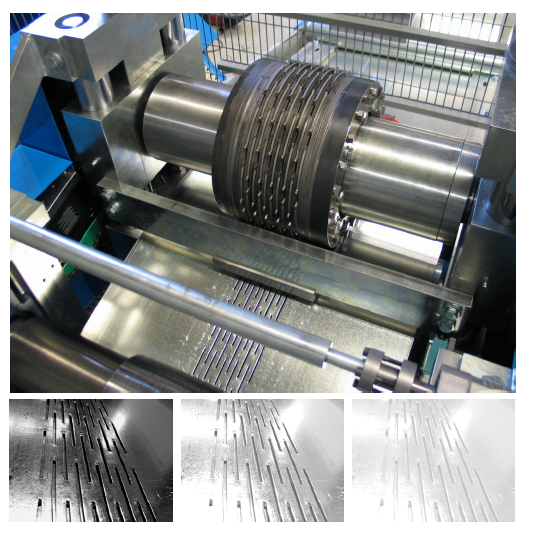

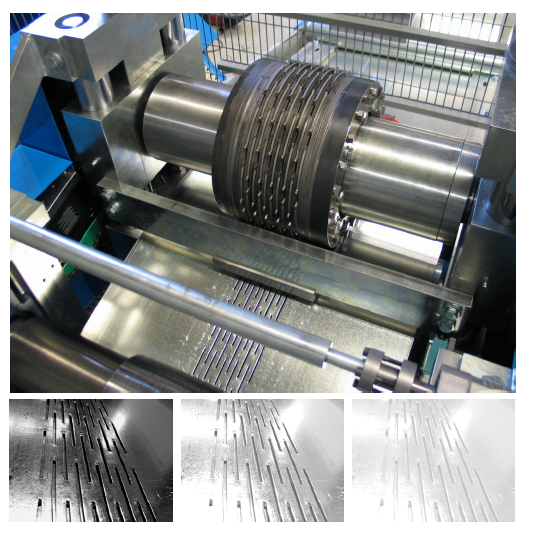

In this particular case, the customer requested a square tube design with perforations, so a punching machine and two hydraulic stations were incorporated to maintain a constant speed. A grader is required for the material to reduce deformation, as well as a servo feeder to ensure accurate drilling. A laser welding machine was used to ensure continuous welding along the material. In addition, the customer chose to include a welding machine for roll change, which facilitates the transition between coils and reduces changeover times.

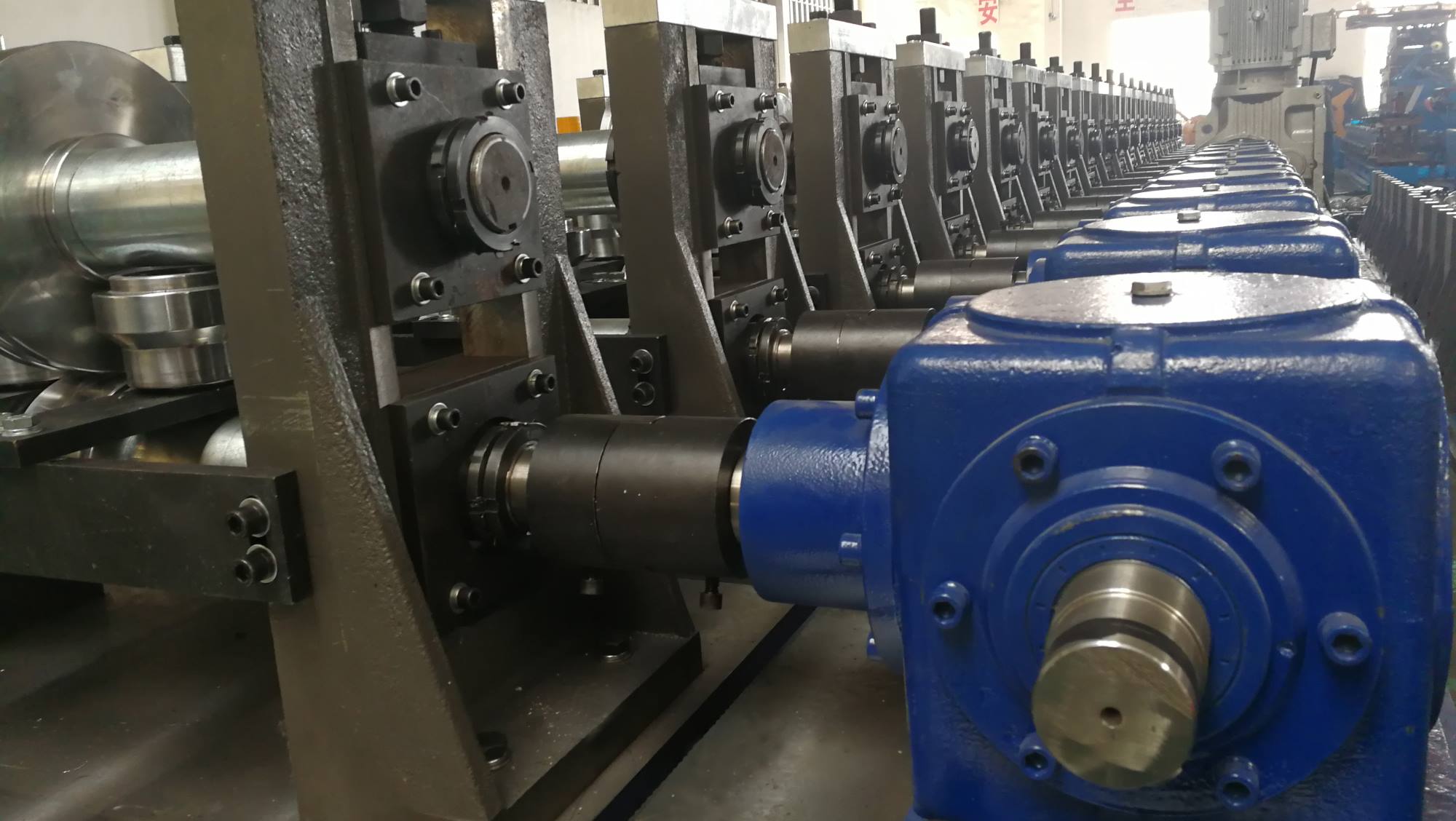

The machine can operate with hot-rolled steels, cold-rolled steels and black steel with a thickness of up to 2 mm. For this reason, a gearbox-type transmission system is recommended, more effective for materials with a thickness greater than 1.5 mm.

If you are looking to create a design that is different from the current market, our team can help you make it possible by knowing your standards and requirements, thus offering you the different options that are most suitable for your company.

All our operating systems are translated into Spanish and English, as are the operating manuals, so that your work team can operate the machine efficiently and safely.

This production line is designed for manufacturing square tubes with a thickness of 2mm, a width ranging from 50-100mm, and a height of 100-200mm.

The line includes the following processes: decoiling, leveling before punching, punching, leveling after punching, roll-forming, laser welding, fume extraction, and cutting.

With its complete configuration and high level of automation, this production line serves as an excellent alternative to traditional welding tube machines, especially when production demands are lower.

Hydraulic decoiler with loading car--Leveler--Servo feeder--Punch press--Hydraulic punch--Limiter--Guiding--Leveler--Roll former--Laser weld--Flying saw cut--Out table

1.Line speed: 5-6m/min, adjustable

2.Suitable material:Hot rolled steel, cold rolled steel, black steel

3.Material thickness: 2mm

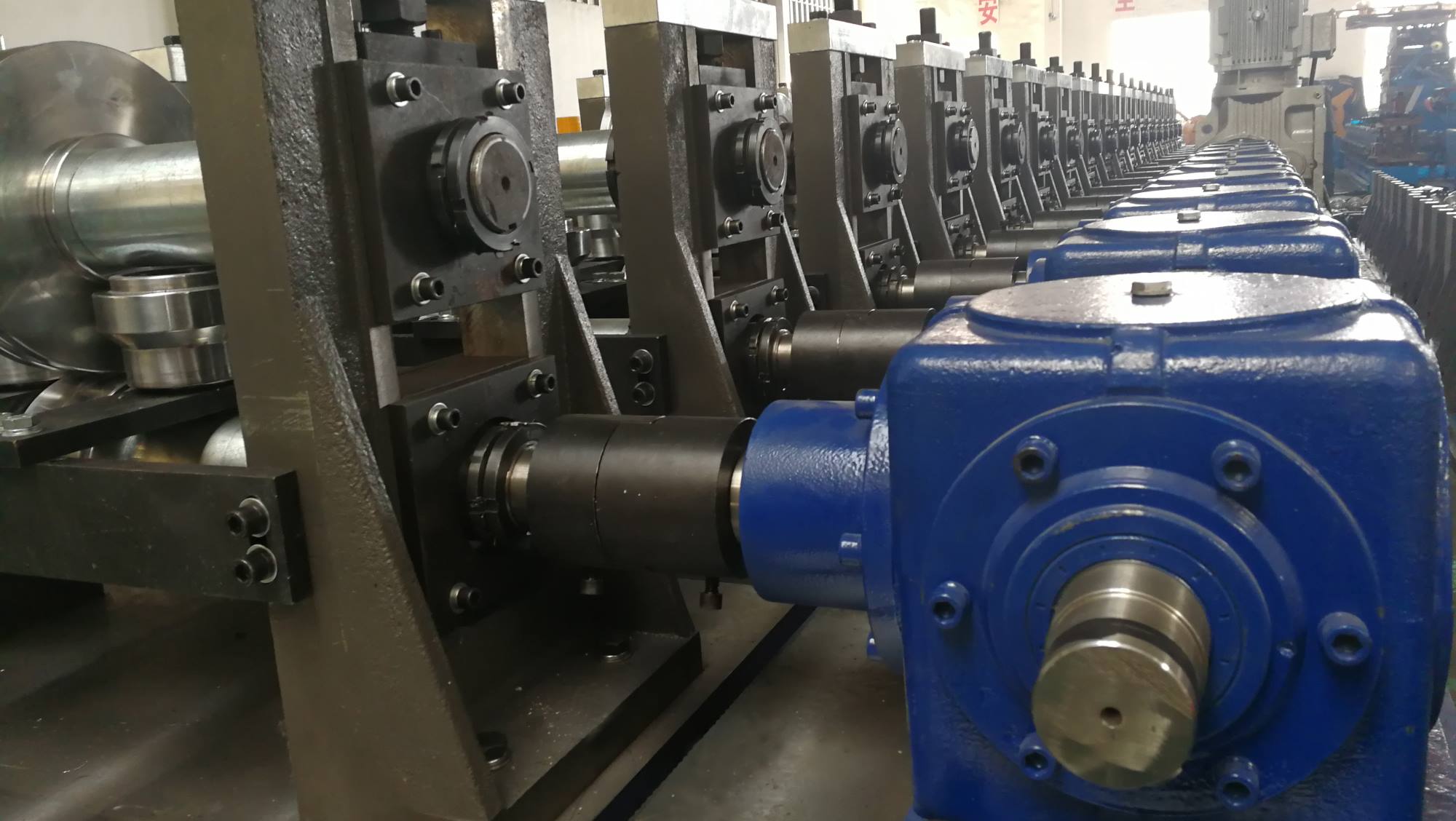

4.Roll forming machine: Cast-iron structure and universal joint

5.Driving system: Gearbox driving system with universal joint cardan shaft.

6.Cutting system: Flying saw cut, roll former doesn’t stop when cutting.

7.PLC cabinet: Siemens system.

1.Hydraulic decoiler*1

2.Standalone Leveler*1

3.Punch press*1

4.Hydraulic punch machine*1

5.Servo feeder*1

6.Integrated Leveler*1

7.Roll forming machine*1

8.Laser welding machine*1

9.Welding Fume Purifier*1

10.Flying saw cutting machine*1

11.Out table*2

12.PLC control cabinet*2

13.Hydraulic station*3

14.Spare parts box(Free)*1

Hydraulic decoiler

* Function: The robust frame is designed for loading steel coils. The hydraulic-powered decoiler ensures a more efficient and safer process for feeding steel coils into the production line.

* Core Expansion Device: The hydraulically driven mandrel or arbor expands and contracts to accommodate steel coils with an inner diameter of 490-510mm, securely clamping the coil for smooth decoiling.

* Press-arm: The hydraulic press-arm holds down the steel coil to prevent sudden uncoiling caused by internal stress, protecting workers from injury.

* Coil Retainer: To prevent the coil from slipping off, it’s easy to install and remove.

* Control System: Equipped with a PLC and control panel, including an emergency stop button for enhanced safety.

Optional Device: Loading Car

* Efficient Coil Replacement: Assists in changing steel coils more safely and efficiently, savinglabor costs.

* Hydraulic Alignment: The platform can hydraulically lift and lower to align with the mandrel. The loading car, equipped with wheels, can move electrically along tracks.

* Safety Design: The concave shape securely holds the steel coil, preventing it from sliding.

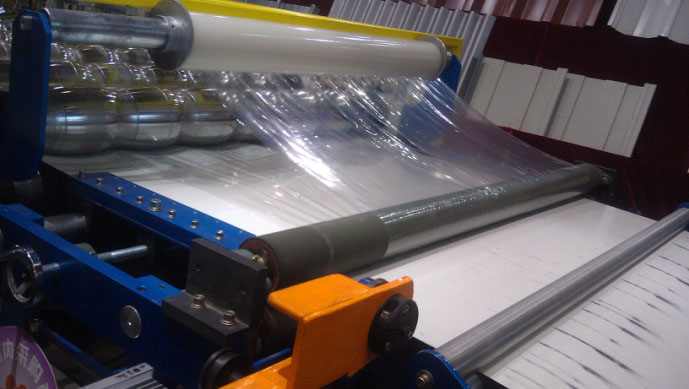

Optional machine: Shearer Butt Welder

* Joins lastand new steel coils, reducing new coil feeding time and adjust

* Saves labor costs and reduces material waste.

* Smooth, burr-free shearing for precise alignment and welding.

* Automated TIG welding for smoothand strong welds.

* Welding table equipped with safety goggles to protect workers' eyes.

* Foot pedal controls for easy coil clamping.

* The machine can be customized for coil width and can be flexibly moved into multiple production lines within its coil width range.

Standalone Leveler

* Eliminates stress and surface irregularities in steel coils through plastic deformation to prevent geometric errors during forming.

* Leveling is essential for coils thicker than 1.5mmand which are required punching.

* Compared to integrated leveler with decoiler or roll forming machine, standalone leveler operatesat a faster speed.

Punching Part(Punch press, hydraulic punch, servo feeder)

* We seta combination of punch press and hydraulic punch for hole punching in this production line. Our engineering team has designed an optimal solution for complex hole patterns, balancing efficiency and cost by leveraging the strengths of both punch machines.

Punch Press

* High-speed.

* High-precision on the holes spacing when punching.

* Suitablefor fixed hole patterns.

Hydraulic Punch

* More flexible for different hole patterns. Different hole shapes have varying punching frequencies, and the hydraulic punch can selectively takedifferent shapes in each punch.

Servo Feeder

* Servo motor-driven feeder for feeding steel coils into punch press or standalone hydraulic punch machine.

* High precision: Servo motors have minimal start-stop delay, allowing accurate control of feed length and hole spacing, significantly reducing scrap from mis-punching.

* Energy efficient: Minimal power consumption during idle phases (when not feeding steel coil andwaiting for instructions), consuming power only during active feeding.

* Programmable: Quickly set step distance and punching speed, saving adjust time when changing the punching mold.

* Internal pneumatic clamping protects the surface of the steel coil from scratches.

Limiter

* Coordinates the production speed, optimizing efficiency and ensuring the safe operation of both the steel coil and the machines.

* When the coil touches the lower sensor, it indicates that the uncoiling, leveling, and punching stages before the limiter are faster than the forming, welding, and cutting stages. These stages before the limiter need to pause to balance the production speed. Otherwise, itwill cause coil accumulation, hindering smooth entry into the forming machine and potentially deforming the coil.

* If the coil touches the upper sensor, it indicates that the latter stages are faster than the earlier ones, so the stages after the limiter need to pause. Otherwise, the coil will be pulled into the roll forming machine, damaging the punching machine and forming rollers.

* Pauses in any stage will prompt a message on the corresponding PLC cabinet screen. Workers can resume production by clicking the prompt.

Guiding

* Main function: Guides the steel coil to align with the machine's centerline, preventing misalignment that can cause twisting, bending, burrs, and dimensional issues in the final product.

* Multiple guiding rollers are located at the feeding entrance and inside the forming machine.

* Regular calibration of guiding devices is necessary after transportation and during long-term operation of the roll forming machine.

* Before shipping, the Linbay team measures and records the guiding width in the user manual for clientto calibrate upon receipt.

Secondary Leveler (Set on the same base with roll forming machine)

* The smoother the coil, the better the alignment of the seams after forming, facilitating welding.

* Secondary leveling enhances the leveling effect and relieves stress at punched areas.

* This leveling is supplementary, and placing it on the forming machine base is a more economical and appropriate solution.

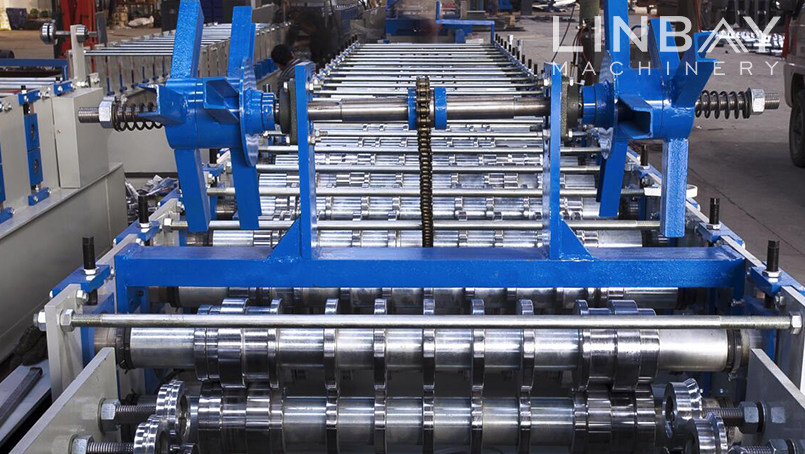

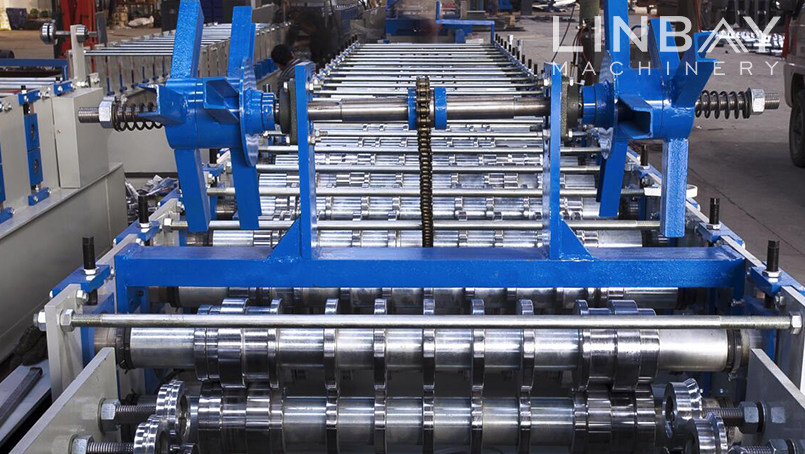

Roll Forming Machine

* Multi-size Production: This line can produce square tubes with widths from 50-100mm and heights from 100-200mm. (Linbay can also customize other size ranges.)

* Automatic Size Adjustment: After setting and confirming the planned newsize on the PLC screen, the forming stations move laterally on the guiding rails to the correct positions, changing the forming point accordingly. This high level of automation provides precision and convenience, saving the cost of manual adjustments.

* Lateral Movement Encoder: Accurately detects the distance of the forming station's movement and promptly feeds the data back to the PLC, keeping movement errors within 1mm.

* Lateral Movement Limiters: Two safety limit sensors are located on the outer side of the guide rails. The inner sensorprevents the forming station from moving too close and colliding, while the outer sensor prevents the stations from moving too far out.

* Cast-iron Stand: An independent upright stand made of cast iron steel, this robust structure is suitable for high-volume production demands.

* Gearbox & Universal Joint: Provides stronger power for advancing coils thicker than 2mm or when forming speeds above 20m/min, ensuring stable operation of the forming machine.

* Rollers: Chrome-plated and heat-treated for rust and corrosion resistance, offering a longer service life.

* Main Motor: Default is 380V, 50Hz, 3Ph, but customization is available.

Laser Weld

* Better quality, high precision, and strong connection.

* Clean and smooth joint.

Welding Fume Purifier

* Absorbs odors and fumes generated during welding, protecting the factory environment and workers' health.

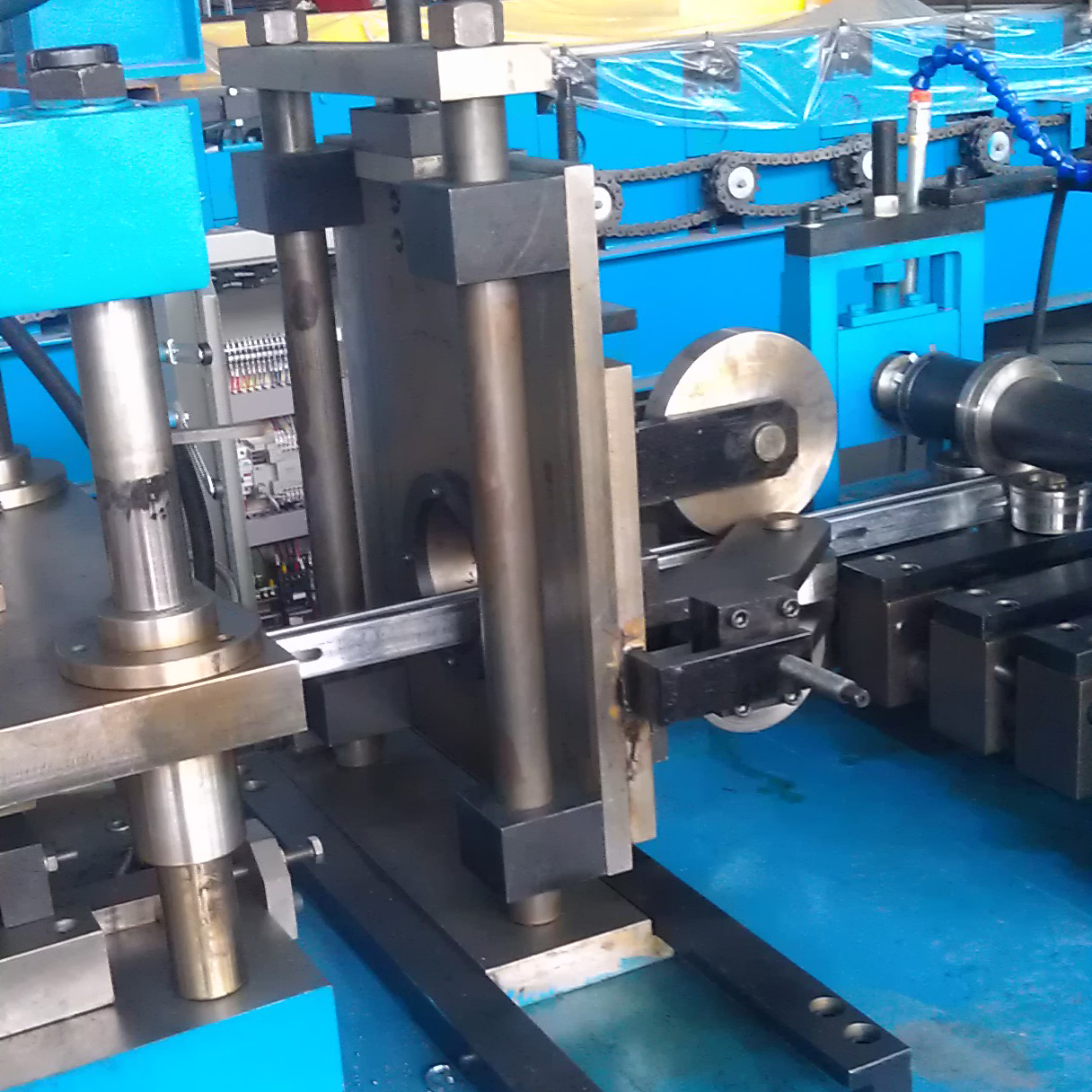

Flying Saw Cut

* Flying: During cutting, the cutter unit moves at the same speed as the roll forming machine, increasing line efficiency and output.

* High Cutting Precision: The cutter unit is equipped with a servo motor and motion controller, maintaining cutting accuracy within ±1mm.

* Saw Cut: Ensures that the edges of the squareclosed shape doesn’t

* Minimal Waste: Each cut produces almost no scrap, saving material cost.

* High Versatility: Unlike other cutting methods that require specific blades for each size, saw cutting is versatile, saving on blade costs.

1. Q: Why buy a Linbay machine?

A: At Linbay we seek to establish long-lasting relationships by offering the best quality and price, as well as unparalleled experience and attention in the market. We have customer service in Mexico and China to solve any questions or inconveniences, backed by our 12 years of experience in the market.

2. Q: What is the delivery time?

A: The lead time is 60 to 80 days, during which we produce, assemble and test to ensure that the machine meets your expectations and required safety standards.

3. Q: How do I get started with my machine?

A: Upon receipt of your machine, an assembly tutorial and operation manual will be provided. We recommend a visit from our technician if this is your first time using a forming machine or if you have doubts about its operation. The technician will explain every detail and train your work team.

4. Q: I want to buy a machine, but I don't know how to get started? What process should I follow?

A: You can start by contacting our sales team via message or email. Afterwards, we will discuss which type of machine best fits your needs and standards. If you want to know more about our company, you can visit our office in Mexico or our factory in China for a tour and observe our manufacturing process. Once you decide to join the Linbay family, we will start manufacturing your machine after signing the contracts and making a 30% down payment.

5. Q: What determines the speed of the forming machine?

A: The speed depends on your profile requirements. In this case, a type of disc cut and a movable base were used to keep the material moving. The combination of components in the machine allows us to achieve a speed of up to 6 m/min.

-

Others

-

scrap collector

-

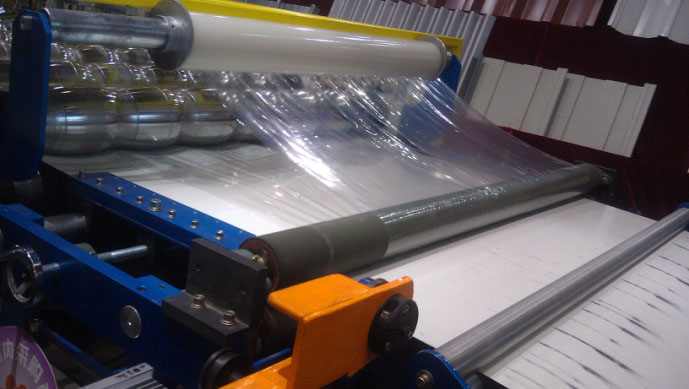

pasting

-

mould change

-

guiding head

-

-

Out table

-

Non-powered

-

auto stacker

-

-

Cutting

-

Sawing cutting

-

flying shear

-

-

Driving

-

chain drive

-

gearbox drive

-

gearbox drive with coupling

-

-

Stands

-

wall panel stands

-

torri stands

-

forged iron stands

-

wall panel for C purlin

-

-

Punching

-

hydraulic punching station

-

punching press

-

roller punching

-

-

Feeding

-

leveling

-

servo feeding

-

-

Decoiler

-

Manual decoiler

-

hydraulic decoiler

-

double head decoiler

-