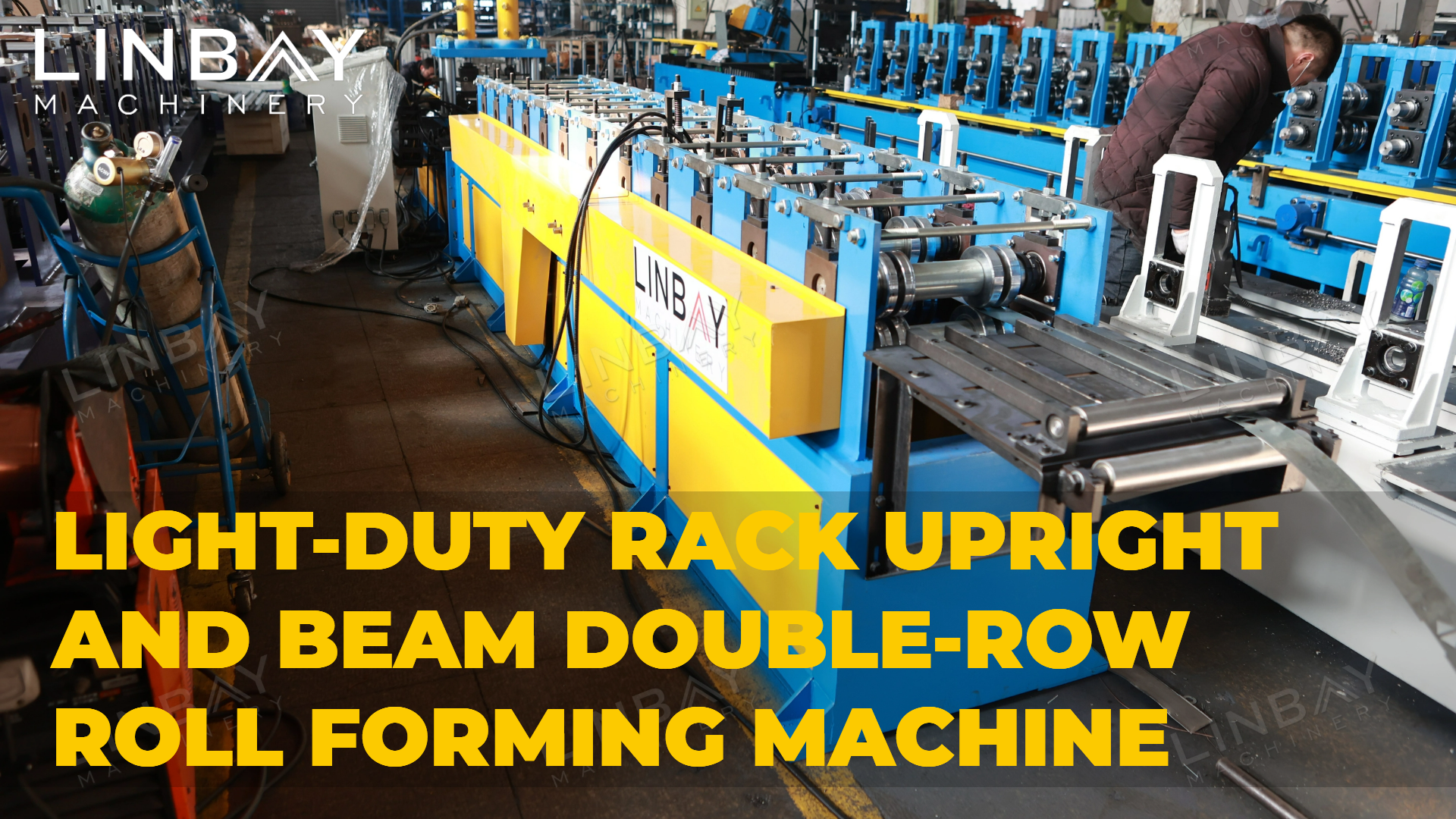

Light-Duty Rack Upright And Beam Double-Row Roll Forming Machine

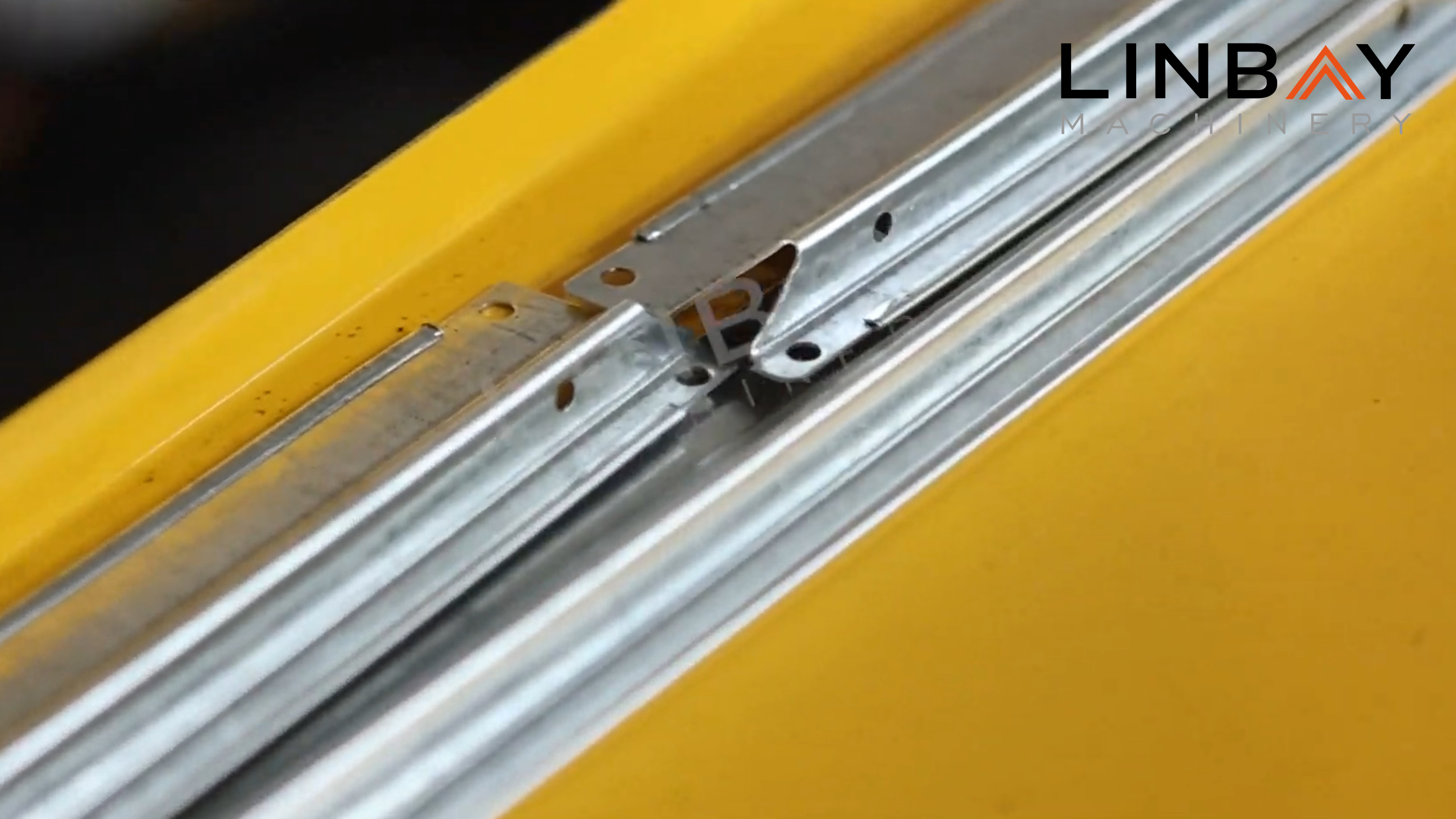

This is a light-duty shelf upright, resembling angle steel, with a thickness of 1.2mm. It is a key component of the shelf structure, and its straightness directly affects the load-bearing capacity of the shelf. Holes are punched on both sides to connect the beams.

This is a light-duty shelf beam with a thickness of 1.2mm, designed to support shelf panels and enhance the overall load-bearing capacity of the light-duty shelf.

Decoiler with leveler--Servo feeder--Hydraulic punch--Roll forming machine--Flying hydraulic cutting--Out table

Linbay offers the light duty (spring) former, which is used as a beam for light loads. This particular profile is assembled using screws.

The machine has a speed of 6-8 m/min. To achieve this, it was necessary to use a flattening unwinder and a servo feeder connected to the punching machine, providing the required precision when punching each section of the sheet. This machine has two different lines, which means that we can produce two different shapes working one at a time. To have two different profiles on the machine, they must have the same number of rollers.

The machine can use galvanized steel or black steel, with a thickness of 1.2mm, according to the specifications requested by the customer.

If you are looking to create a design that is different from the current market, our team can help you make it possible by knowing your standards and requirements, thus offering you the different options that are most suitable for your company.

All our operating systems are translated into Spanish and English, as are the operating manuals, so that your work team can operate the machine efficiently and safely.

Decoiler with Leveler

This machine integrates the functions of decoiling and leveling. The decoiler features a brake device to adjust the tension of the decoiling roller, ensuring smooth decoiling speed. Additionally, protective leaves made of steel are installed to prevent the steel coil from slipping during the decoiling process. This design provides a cost-effective and high-security decoiling machine.

Subsequently, the steel coil enters the leveling machine. The steel coil used this case is only 1.2mm thick. However, due to the requirement for dense punching, it is crucial to use a leveler to eliminate the curvature of the steel coil, thereby enhancing its flatness and parallelism. This, in turn, improves the quality of the steel coil and the final product. The leveling machine is equipped with 3 upper leveling rollers and 4 lower leveling rollers.

Servo Feeder & Hydraulic Punch

The steel coil then enters an independent hydraulic punch machine. Due to the fast response and minimal start-stop time of the servo motor, it allows precise control of the punching position. Therefore, we use a servo motor to power the feeder for accurate punching.

Limiter

In the middle of the punching and roll forming processes, there is a limiter to coordinate production speed. When the steel coil reaches the lower limiter, signaling that the punching speed is greater than the roll forming speed, the hydraulic punch receives a signal from the PLC control cabinet to stop working. A prompt alarm appears on the PLC screen, and the operator can resume work by clicking on the screen. And, during the few seconds between punching stopping and resuming, the roll forming machine keeps working.

Conversely, when the steel coil reaches the upper limiter, signaling that the forming speed is greater than the punching speed, the roll forming machine stops working. During the few seconds between the roll forming machine stopping and restarting, the hydraulic punch keeps working. The height of the upper limiter can be moved up or down according to customer needs.

This ensures overall coordination and uniform production speed of the production line.

Guiding

Before the steel coil enters the first forming roller, it passes through a guiding bar to keep the steel coil and the machine on the same centerline, preventing distortion of the formed profiles. Guiding rollers are strategically placed not only at the entry point but also along the entire forming line. Measurements of each guiding bar/roller's distance to the edge are recorded in the manual for accurate adjustment if slight displacement occurs during transport or misalignment made by workers during production.

Roll Forming Machine

The roll forming machine is the most crucial part of the entire production line. This roll forming machine has a total of 12 forming stations and features a wall panel structure and chain driving system. It is noteworthy that this roll forming machine is a double-row structure, capable of producing two different shapes – upright and beam for light-duty shelving. Although these two rows cannot work simultaneously, it offers flexibility for varied production needs. Protective covers are installed on the chain to ensure worker safety. The roll forming machine is tested using steel coils with the same yield strength as those used in customer production, ensuring immediate production convenience upon delivery.

The material of the forming rollers is Gcr15, a high-carbon chromium bearing steel known for its hardness and wear resistance. Chrome plating on the roller surface extends its lifespan, while the shafts are made of heat-treated 40Cr material.

Flying Hydraulic Cutting & Encoder

The roll forming machine incorporates a Japanese Koyo encoder, converting the sensed steel coil length into electrical signals transmitted to the PLC control cabinet. This allows the cutting machine to control cutting errors within 1mm, ensuring high-quality products and minimizing waste from incorrect cuts. "Flying" refers to the ability of the cutting machine to move back and forth at the same speed as the roll forming machine during cutting, allowing continuous operation of the roll forming machine and increasing the overall production line capacity.

Hydraulic Station

The hydraulic station is equipped with a cooling electric fan for efficient heat dissipation, ensuring prolonged, low-fault operation, and durability.

PLC

Workers can control production speed, set production dimensions, cutting lengths, etc., through the PLC screen. The PLC control cabinet includes protective functions such as overload, short circuit, and phase loss protection. The language of the PLC screen can be customized in a certain language or multiple languages according to customer needs.

Warranty

Before delivery, the delivery date is indicated on the nameplate, starting a two-year guarantee for the entire production line and a five-year warranty for rollers and shafts.

| Bracing Roll Forming Machine | ||

| Machinable Material : | A) Zinc-plated steel | Thickness(MM): 0.9-2 |

| B) Hot rolled steel | ||

| C) Cold rolled steel | ||

| Yield strength : | 200 - 350 Mpa | |

| Tensil stress : | G200 Mpa-G350 Mpa | |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Punching system : | Hydraulic punch station | |

| Forming station : | 14 stands | * According to your profile drawings |

| Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Wall panel station | * Cast Iron (Optional) |

| Forming speed : | 10-15 (M/MIN) | |

| Rollers’ material : | Steel #45, chromed | * GCr 15 (Optional) |

| Cutting system : | Post-cutting | * Pre-cutting (Optional) |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz 3ph | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

1. Q: Why buy a Linbay machine?

A: Because at Linbay we seek to create relationships that last for years, that is why we offer you the best quality and price, as well as experience and attention unmatched in the market. We have service in Mexico and China, and we will take care of any questions or inconveniences you may have. In addition, our 12 years in the market support us.

2. Q: What is the delivery time?

A: From 60 to 80 days, after producing and assembling the different components. Depending on your requirements, we must carry out various tests to ensure that your machine meets your expectations and the required safety standards.

3. Q: How do I get started with my machine?

A: Upon the arrival of your machine, you will be given a tutorial on how to assemble it and a manual to learn how to operate it. If this is the first time you buy a forming machine or you have doubts about its operation, it is recommended to visit our technician, who will be in charge of explaining every detail of the machine, as well as training your work team in its operation.

4. Q: I want to buy a machine, but I don't know how to get started? What process should I follow?

A: You can start by sending a message or email to our sales team. You can then describe the type of machine you're looking for and which one best fits your standards. If you want to continue with the process, but have questions about our company, you can visit our office in Mexico or our factory in China, where you can take a tour of our facilities and learn about each manufacturing process of your machine. If you decide to join the Linbay Family, we will start the manufacture of the machine after signing the contracts and making the 30% advance payment.

5. Q: What will the speed of the forming machine depend on?

A: The right speed will depend on the design you are looking for. In the case of a machine with two different profiles with perforation, it can reach up to 8 m/min. If drilling is not required, it could reach an even faster speed.

-

Out table

-

Non-powered

-

Auto-stacker

-

-

Cutting

-

Saw cutting

-

fast flyting cutting

-

-

Driving

-

chain driving system

-

gearbox driving system

-

Gearbox with couplings

-

-

Stands

-

Torri Stands

-

Forged Iron Stands

-

Wall Panel

-

ruler

-

-

Punching

-

Hydraulic punching station

-

Fast Roller Punching system

-

Punching press

-

-

Feeding

-

Servo feeder

-

Leveler

-

-

Decoiler

-

Motorized&Hydraulic decoiler

-

Double head motorized decoiler

-

Manual Decoiler

-