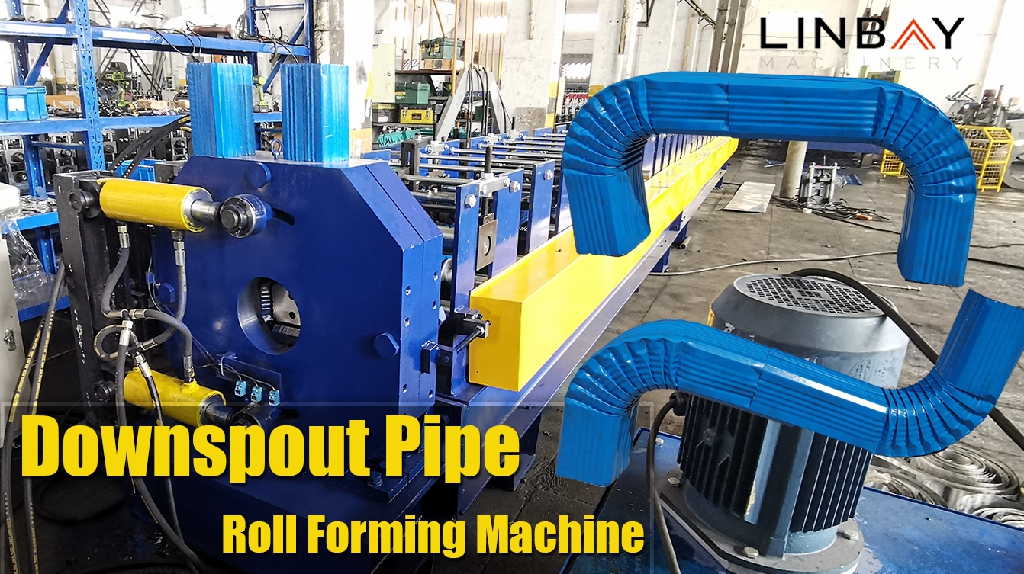

Downspout Pipe Roll Forming Machine

The speed can reach up to 15m/min, with panel structure and chain-type transmission system, for this configuration we can use a thickness from 0.4mm to 0.6mm or 1.5mm to 2.0mm. We can use as raw material, galvanized steel, aluminum, painted steel, stainless steel and copper. To determine the length of our downspouts it is only necessary to stipulate on the screen how many parts we need and what length, you can make a list of up to 10 different lengths without having to stop the machine for a second.

If you want to manufacture elbows, we can sell the machine to be able to make 90 and 40 degree elbows or incorporate it into the forming machine which could slow down the production speed.

If you are looking to create a design that is different from the current market, our team can help you make it possible by knowing your standards and requirements, thus offering you the different options that are most suitable for your company.

All our operating systems are translated into Spanish and English, as are the operating manuals, so that your work team can operate the machine efficiently and safely.

Description:

Linbay exported this round downspout pipe roll forming machine to South Africa on 2008, Australia on 2016 and to Kyrghyzstan on 2017. This configuration is affordable and practical to any company.

Description:

This square downspout pipe roll forming machine is a complete line that can produce pipe and elbow in one machine. We use servo motor as main forming power, it improves pipe’s precision. At last process, we not only offer a hydraulic cut, but also a elbow machine and a shrink device. It’s a good choice for you.

|

Downspout Pipe Roll Forming Machine |

||

|

Machinable Material : |

A) Aluminum |

Thickness (MM):0.4-0.6, 1.5-2 |

|

B) Copper |

||

|

C) Galvanized steel |

||

|

D) Painted steel |

||

|

E) Galvalume |

||

|

Yield strength : |

250 - 350 Mpa |

|

|

Tensil stress : |

300 Mpa-500 Mpa |

|

|

Decoiler : |

Hydraulic decoiler |

* Manual decoiler (Optional) |

|

Forming station : |

20-24 |

* According to your profile drawings |

|

Main machine motor brand : |

Shanghai Dedong (Sino-Germany Brand) |

* Siemens (Optional) |

|

Driving system : |

Chain drive |

* Gearbox drive (Optional) |

|

Machine structure: |

Wall panel station |

* Torri station (Optional) |

|

Forming speed : |

10-15 (M/MIN) |

* Or according to your profile drawings |

|

Rollers’ material : |

Steel #45 |

* GCr 15 (Optional) |

|

Cutting system : |

Post-cutting |

* Elbow mould/shrink mould (Optional) |

|

Frequency changer brand : |

Yaskawa |

* Siemens (Optional) |

|

PLC brand : |

Panasonic |

* Siemens (Optional) |

|

Power supply : |

380V 50Hz 3ph |

* Or according to your requirment |

|

Machine color : |

Industrial blue |

* Or according to your requirment |

|

Elbow Machine Specification |

|

|

Suitable pipe thickness(MM): |

0.4-1.5 MM |

|

Machineable shape: |

round pipe/square pipe. |

|

Elbow angle : |

30° |

|

45° |

|

|

75° |

|

|

90° |

|

|

Motor power(KW) : |

2.5 KW |

|

Other function : |

Automatic shrink mould |

|

Machine size(MM): |

1200x650x1500 |

1. Q: Why buy a Linbay machine?

A: At Linbay we seek to establish long-lasting relationships by offering the best quality and price, as well as unparalleled experience and attention in the market. We have customer service in Mexico and China to solve any questions or inconveniences, backed by our 12 years of experience in the market.

2. Q: What is the delivery time?

A: The lead time is 40 to 50 days, during which we produce, assemble and test to ensure that the machine meets your expectations and required safety standards.

3. Q: How do I get started with my machine?

A: Upon receipt of your machine, an assembly tutorial and operation manual will be provided. We recommend a visit from our technician if this is your first time using a forming machine or if you have doubts about its operation. The technician will explain every detail and train your work team.

4. Q: What process do I need to follow to buy a machine?

A: You can start by contacting our sales team via message or email. Afterwards, we will discuss which type of machine best fits your needs and standards. If you want to know more about our company, you can visit our office in Mexico or our factory in China for a tour and observe our manufacturing process. Once you decide to join the Linbay family, we will start manufacturing your machine after signing the contracts and making a 30% down payment.

-

Out table

-

Non-powered

-

Auto-stacker

-

-

Cutting

-

Saw cutting

-

fast flyting cutting

-

-

Driving

-

chain driving system

-

gearbox driving system

-

Gearbox with couplings

-

-

Stands

-

Torri Stands

-

Forged Iron Stands

-

Wall Panel

-

ruler

-

-

Punching

-

Hydraulic punching station

-

Fast Roller Punching system

-

Punching press

-

-

Feeding

-

Servo feeder

-

Leveler

-

-

Decoiler

-

Motorized&Hydraulic decoiler

-

Double head motorized decoiler

-

Manual Decoiler

-