Half-round ridge cap roll forming machine

Linbay offers the roll forming machine for Half-round ridge cap, which has the function of preventing water seepage at the top of the roof, as well as giving a more aesthetic view to the roof, it is usually installed with galvateja.

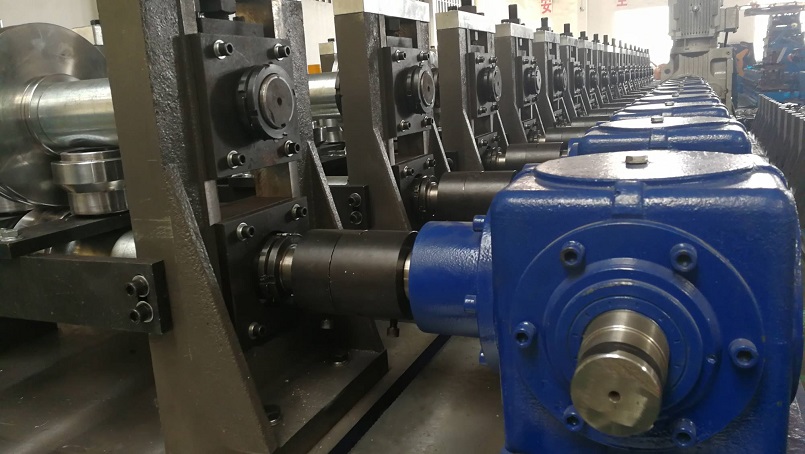

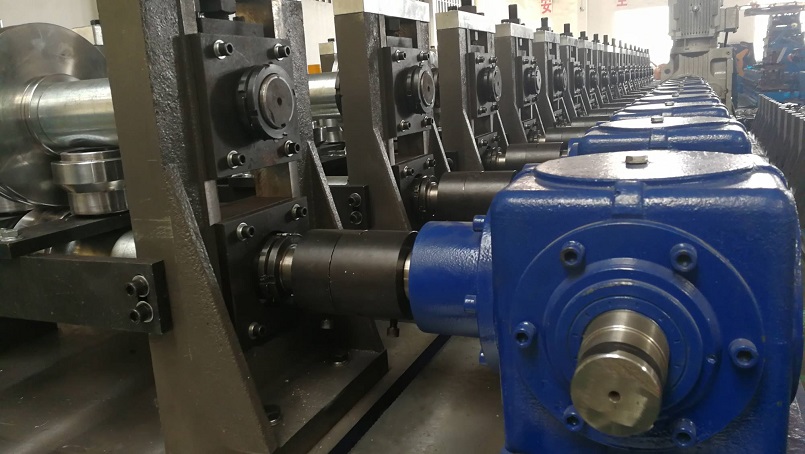

The machine has a speed of up to 4m/min, usually has a thickness of 0.3mm to 0.5mm, using galvanized steel, galvalume, and painted polyester as raw material. The machine is manufactured with a panel base on the sides of the axles and chain as a transmission system, it has 16 steps to shape the profile, to determine the desired length we only have to modify it on the screen of the electrical cabinet, where we can control the length, as well as the holes that are required. An option with wrought iron structure and gearboxes are offered, improving speed, providing greater stability and improving operation.

If you are looking to create a design that is different from the current market, our team can help you make it possible by knowing your standards and requirements, thus offering you the different options that are most suitable for your company.

All our operating systems are translated into Spanish and English, as are the operating manuals, so that your work team can operate the machine efficiently and safely.

The ridge cap covers the joint between the two slopes, sealing off the area from rain and dust. They come in various shapes to match different types of metal roofing panel,made from the 0.3-0.6mm color coated steel, PPGI and galvanized steel.

Real case-Flow chart

Decoiler--Guiding--Roll forming machine--Hydraulic punch--Hydraulic cut--Out table

1.Line speed: 0-10m/min, adjustable

2.Suitable material: Color coated steel, galvanized steel and PPGI

3.Material thickness: 0.3-0.6mm

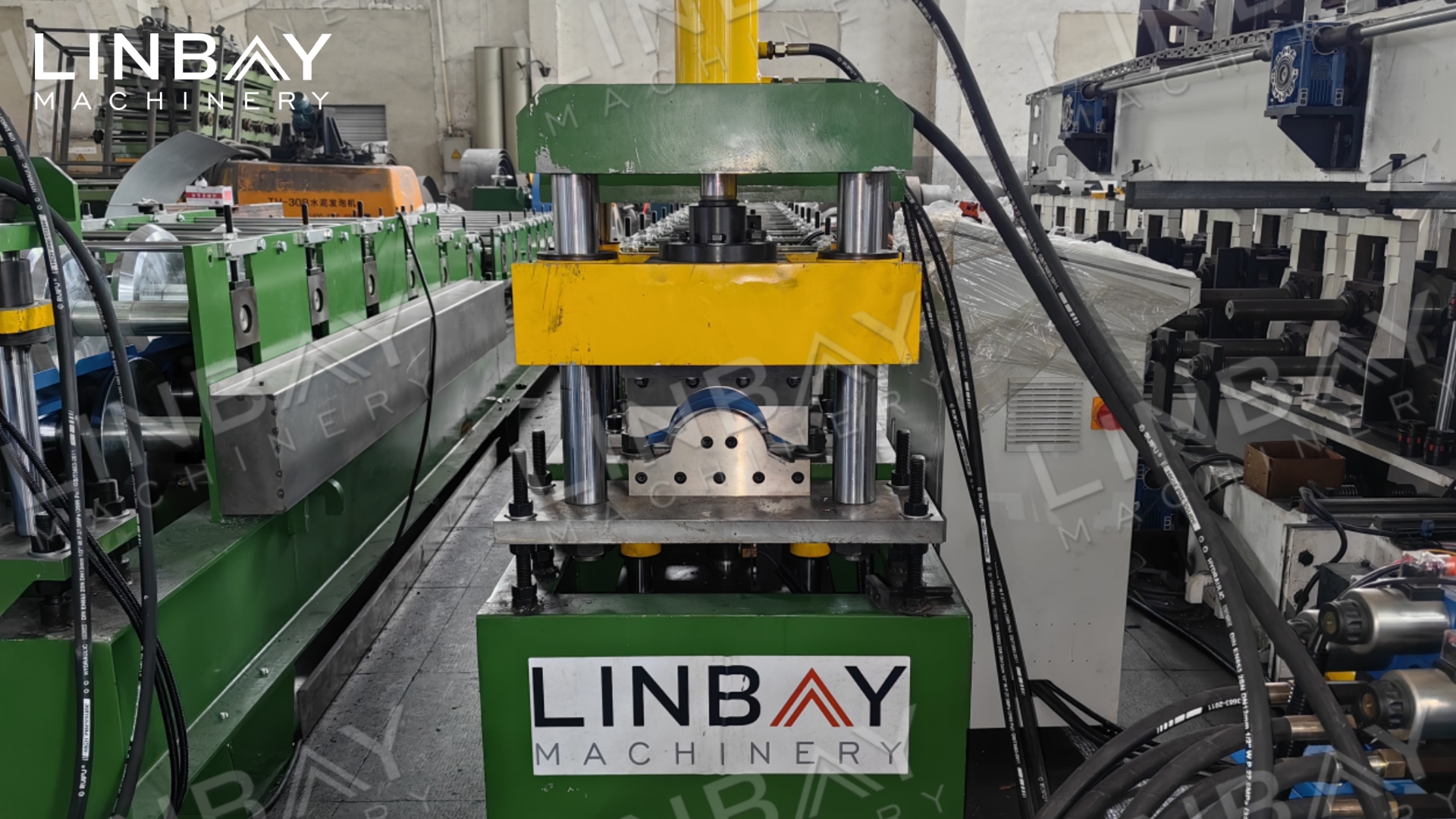

4.Roll forming machine: Wall-panel structure

5.Driving system: Chain system

6.Cutting system:Hydraulic cutting, the roll former stops when cutting.

7.PLC cabinet: Siemens system.

1.Manual decoiler*1(We also offer electrical and hydraulic decoiler, know more in DESCRIPTION below)

2.Roll forming machine*1

3.Hydraulic punch machine*1

4.Hydraulic cutting machine*1

5.Out table*2

6.PLC control cabinet*1

7.Hydraulic station*1

8.Spare parts box(Free)*1

Decoiler

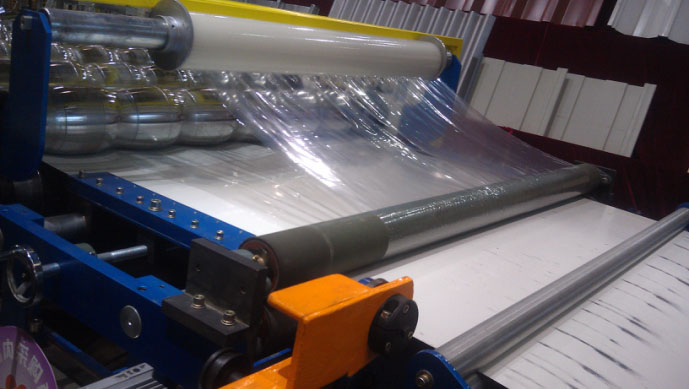

The decoiler comes in manual (non-powered), electric, and hydraulic models, chosen based on the thickness, width, and weight of the steel coil. A manual decoiler is sufficient to stably support the 0.6mm thick coil and ensure smooth uncoiling.

The central shaft of the uncoiler is used to place the steel coil, also called core expansion device, capable of expanding and contracting to fit coil inner diameters between 460-520mm, ensuring safe and smooth uncoiling. We also equip it with an outward coil retainer to prevent the coil from slipping off, ensuring worker safety.

Guiding

Guide rollers assist the steel coil in entering the roll forming machine and ensure the coil aligns with the same centerline of other machines. This guarantees the straightness of the ridge cap and the accuracy of the forming pressure points.

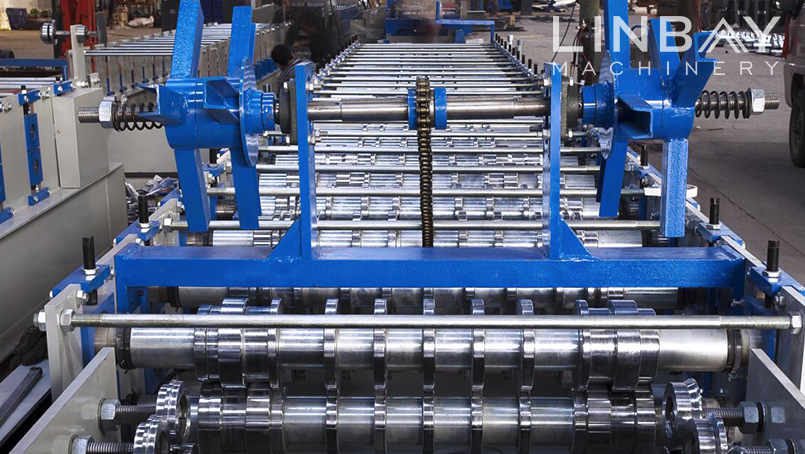

Roll forming machine

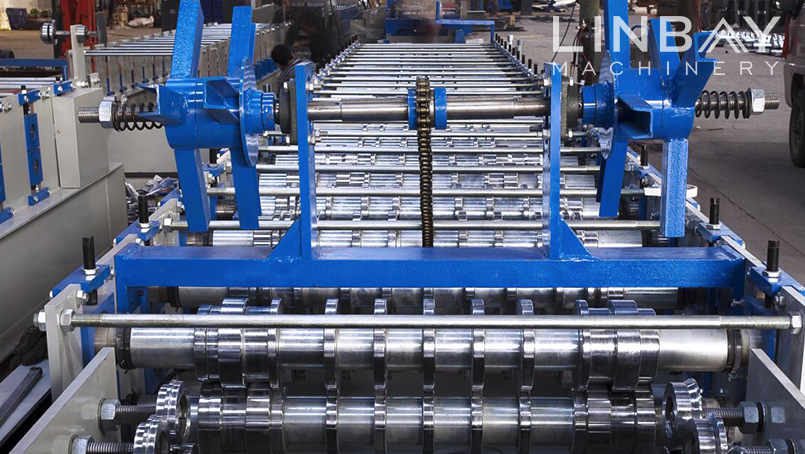

The wall panel structure and chain driving system can effectively form thin sheets with thicknesses of 0.3-0.6mm, making it a cost-effective choice. The chain is covered by an iron casing, which protects both the workers from hurt and the chains from debris damage. Under the action of the forming rollers, the steel coil undergoes pressure and tensile forces, achieving the desired shape.

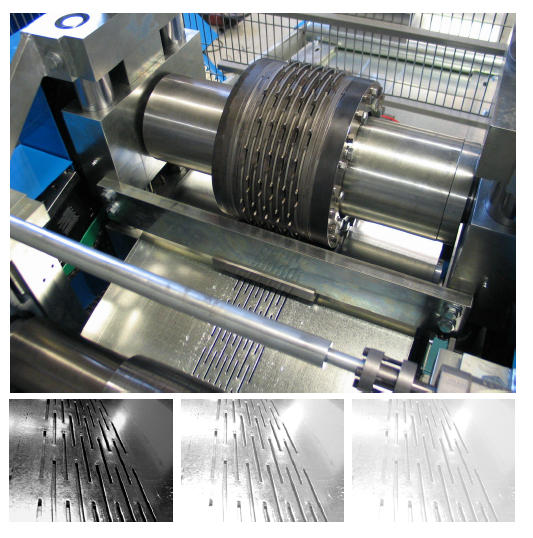

There are 16 forming stations in total, each accurately designed according to the client's drawings, considering wave height, arc radius, and straight edges on ridge cap’s both sides, without scratching the coil surface or the paint coating.

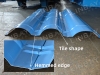

This ridge cap features hemmed edges to reduce sharpness and protect workers from getting hurt. Additionally, the hemmed design conceals the edge of the metal to prevent edge creep, minimizing rust formation at the ridge cap edge.

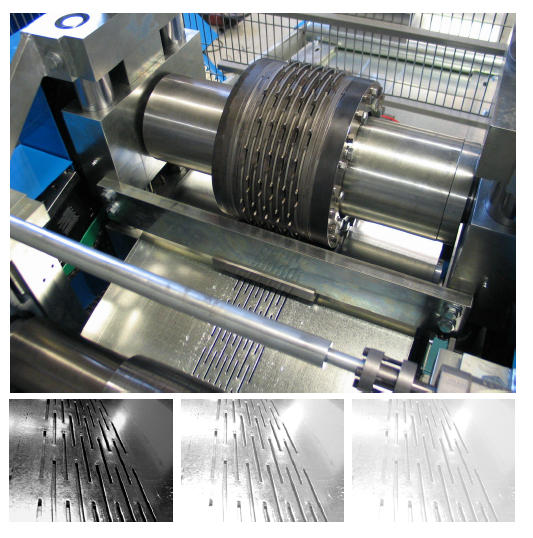

Stamping

After forming, the steel coil has a semi-circular shape. Then, we use a hydraulic punch machine to stamp the tile's raised shape. This is done both for profiling and to increase the ridge cap's longitudinal strength. The stamping interval can be set on the PLC screen. The stamping mold can be customized according to your drawings.

Encoder, PLC Control Cabinet, & Hydraulic cutting

The encoder precisely detects the length of the advancing steel coil and converts it into an electrical signal, which is transmitted to the PLC control cabinet. Workers can set production speed, batch quantity, and cutting length on the PLC cabinet screen. With accurate feedback from the encoder, the hydraulic cutting machine can control the cutting length error within ±1mm.

The cutting blades are precisely customized according to the drawings, ensuring the cutting edges are not deformed and have no burrs.

:

1. Q: Why buy a Linbay machine?

A: At Linbay we seek to establish long-lasting relationships by offering the best quality and price, as well as unparalleled experience and attention in the market. We have customer service in Mexico and China to solve any questions or inconveniences, backed by our 12 years of experience in the market.

2. Q: What is the delivery time?

A: The lead time is 60 to 80 days, during which we produce, assemble and test to ensure that the machine meets your expectations and required safety standards.

3. Q: How do I get started with my machine?

A: Upon receipt of your machine, an assembly tutorial and operation manual will be provided. We recommend a visit from our technician if this is your first time using a forming machine or if you have doubts about its operation. The technician will explain every detail and train your work team.

4. Q: What process do I need to follow to buy a machine?

A: You can start by contacting our sales team via message or email. Afterwards, we will discuss which type of machine best fits your needs and standards. If you want to know more about our company, you can visit our office in Mexico or our factory in China for a tour and observe our manufacturing process. Once you decide to join the Linbay family, we will start manufacturing your machine after signing the contracts and making a 30% down payment.

-

Others

-

Scrap Collector

-

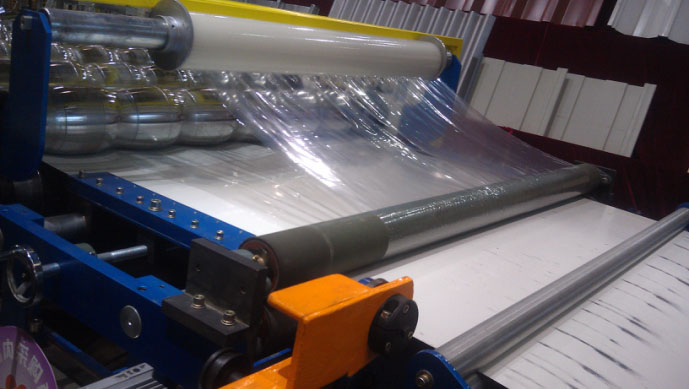

Pasting

-

Mould Change

-

Guiding Head

-

Cooling System

-

-

Out table

-

Non-Powered

-

Auto Stacker

-

-

Cutting

-

Fixed Saw Cutting

-

Flying Shear

-

Universe Cutting

-

-

Driving

-

Chain Drive

-

Gearbox Drive

-

Gearbox Drive With Coupling

-

-

Stands

-

Wall Panel

-

Torri Stands

-

Forged Iron Stands

-

Wall Panel For C Purlin

-

-

Punching

-

Hydraulic Punching Station

-

Punching Press

-

Roller Punching

-

-

Feeding

-

Leveling

-

Servo Feeding

-

-

Decoiler

-

Manual Decoiler

-

Hydraulic Decoiler

-

Double Head Decoiler

-