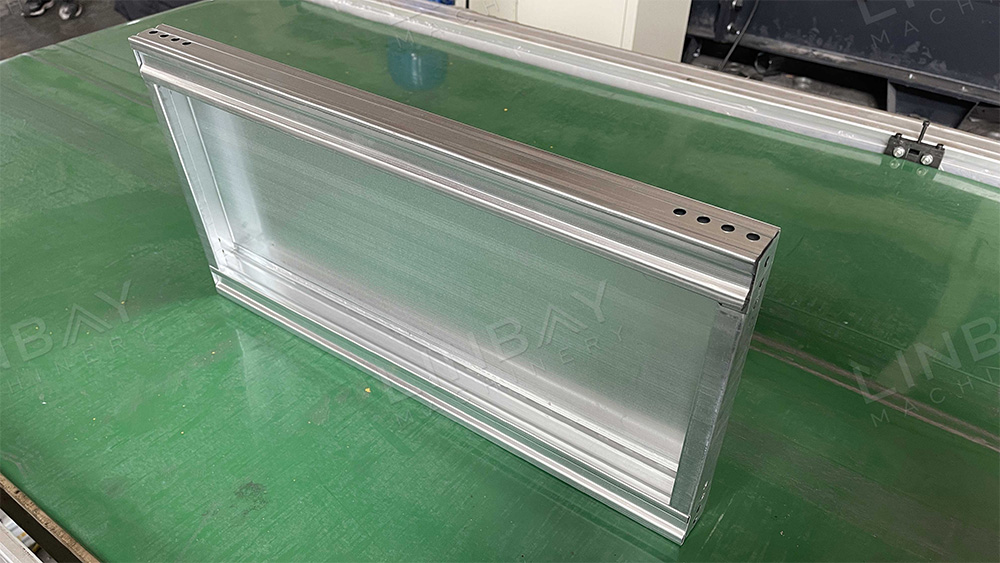

Shelf Panel Roll Forming Machine

In the shelf system, we classify them into three main types according to their load-bearing capacity: light, medium and heavy. As shown in the picture, this is a very typical type of shelving structure, consisting mainly of racks, shelf panels, beams and bracing. Light duty shelving may not require bracing and heavy duty shelving may not require shelf panels, only need to follow customers’ specific needs. Shelving systems are also a very important part of our business and we are very experienced with other profiles of shelving systems.

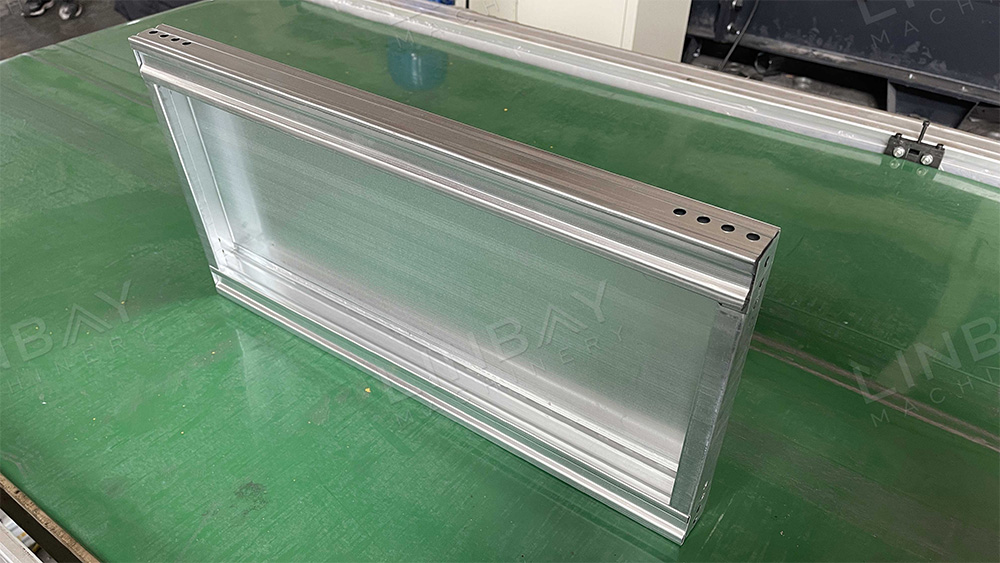

Shelf panels can also be divided into single, double or triple folds, and the forming process can be adjusted according to times for bending.

More information of other profiles:

Upright rack roll forming machine

-

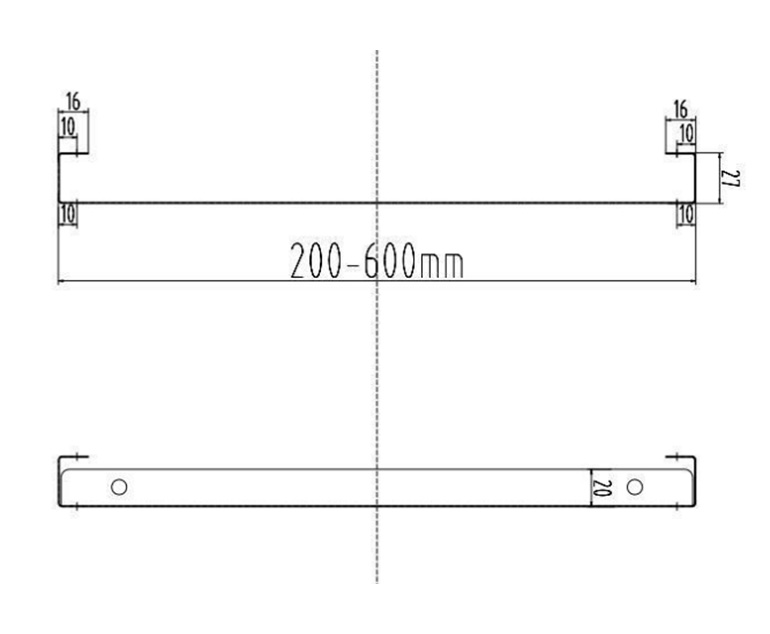

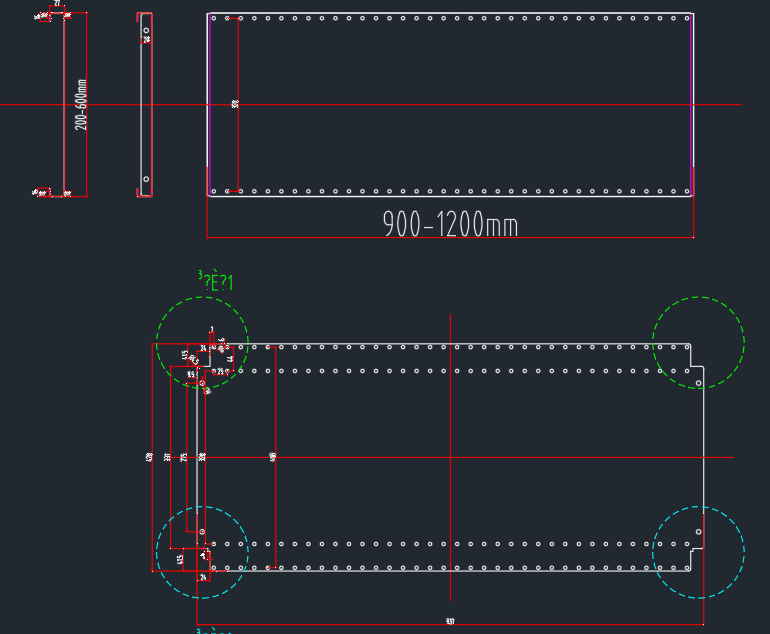

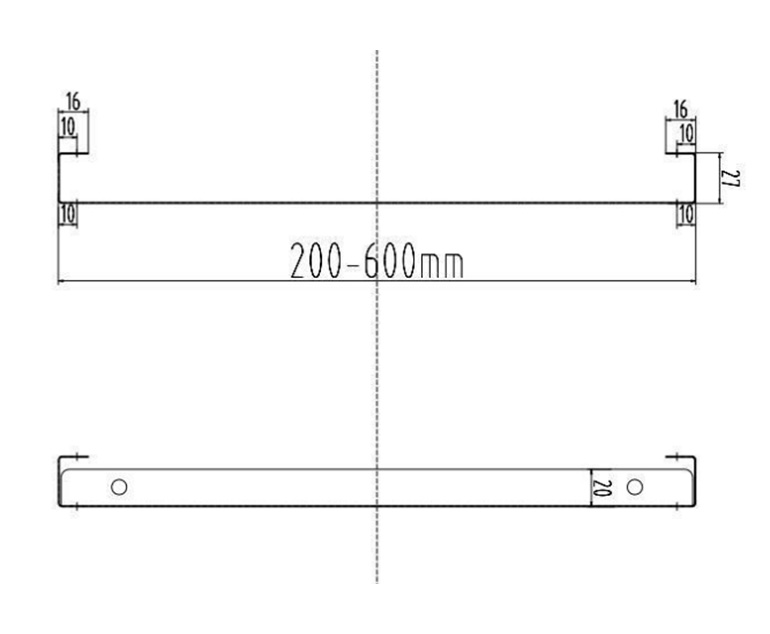

(Drawing)

-

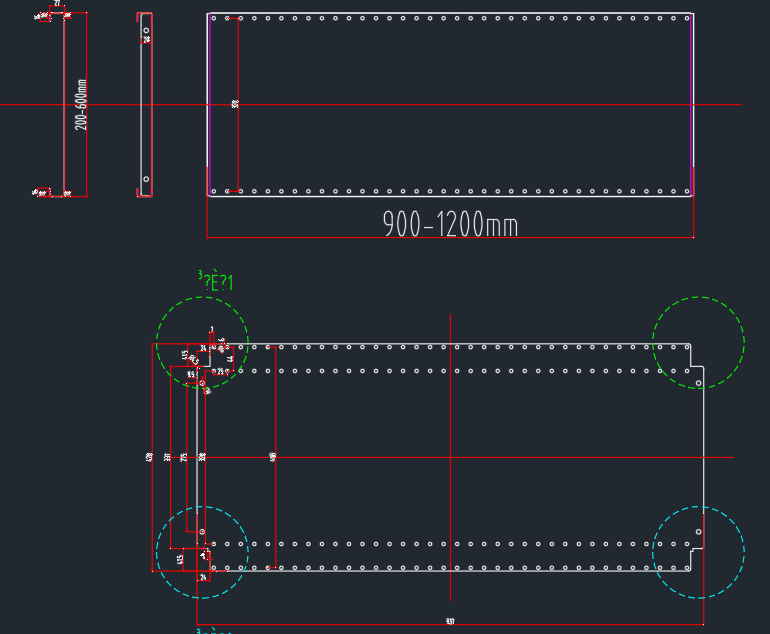

(Punch)

The profile here is a single fold shelf panel. With a width range of 200-600mm, fixed height and a length range of 900-1200mm and a material thickness range of 0.6-0.8mm, the shelf panel will have punched holes to create notches for subsequent bending. The speed of the entire line is around 0-8m/min. Here of course the length and width as well as the production speed are adjustable. Please contact us to send us details about your specific profile and we will customize a machine that is more suitable for you.

We produce profiles in accordance with ISO, CE and UL standards and our machines are suitable for use in warehouses, supermarkets, industry or at home.

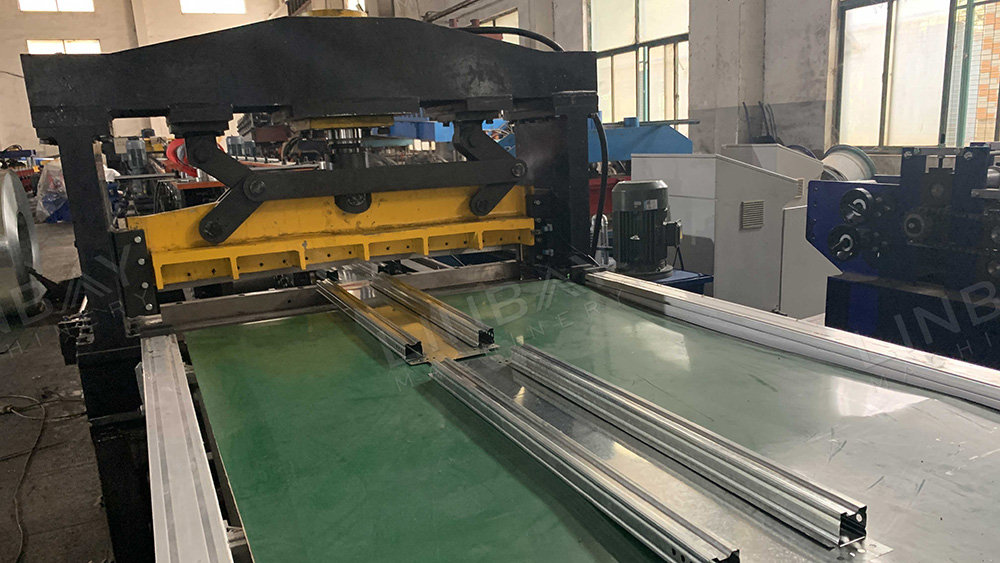

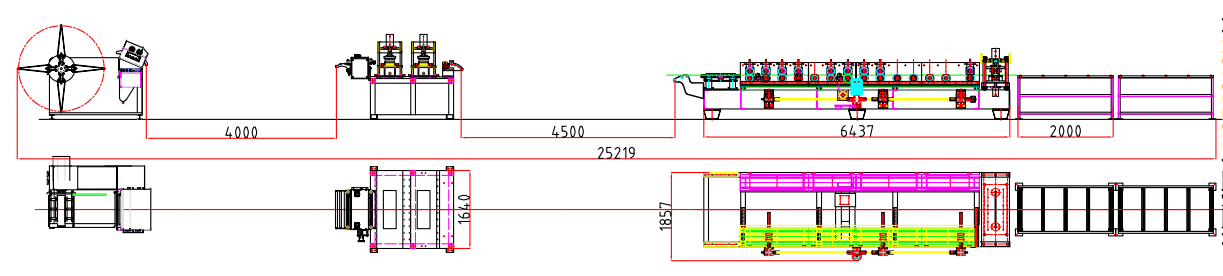

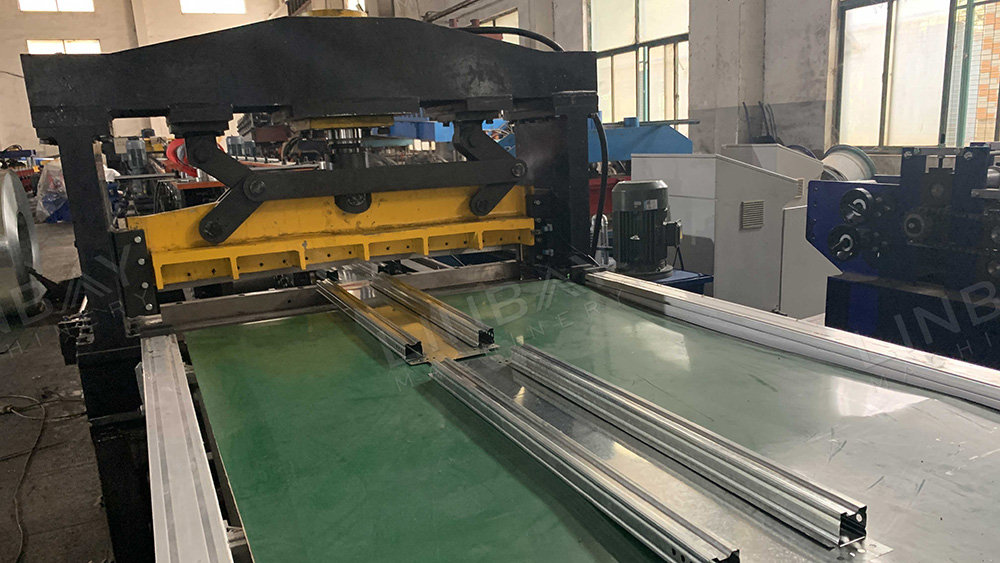

The whole process is from hydraulic decoiler with leveler, servo feeder, hydraulic punch, guiding, roll forming machine, hydraulic cut with flanging, then out tables. In the case of double fold shelf panels, twice bending machine will be the needed.

Linbay offers the shelf panel forming machine, which is responsible for supporting a light load. Depending on the needs, you can choose from 0 to 3 folds in this type of profile.

The machine has a speed of 3 m/min to 4 m/min, which will depend on the desired design. The width of the desired shelf can be automatically changed by means of the servo motor, which we can control from the screen of our cabinet. To do this, you must also consider what the desired measurements are along the length and width of the piece, as well as the design, since each order is personalized and must match the blade.

The machine can use galvanized steel, with a thickness from 0.3mm to 0.6mm. If any other material or thickness is required, it can be modified according to your needs. This is just one example of the machines we have manufactured.

If you are looking to create a design that is different from the current market, our team can help you make it possible by knowing your standards and requirements, thus offering you the different options that are most suitable for your company.

All our operating systems are translated into Spanish and English, as are the operating manuals, so that your work team can operate the machine efficiently and safely.

Hydraulic decoiler with leveler--Servo feeder with hydraulic punch--Guiding--Roll former--Hydraulic cut+flanging--Out tables

The shelf panel roll forming machine has been designed for producing single fold shelf panel profile.

It adopts a 5 ton hydraulic decoiler with leveler, it can help our customers save much space and cost less compared to a separate leveler and decoiler. Hydraulic motor power is 3kw, same as motor for leveling. 7 leveling rollers with a diameter of 80mm, leveling speed is same with decoiling speed 0-20m/min.

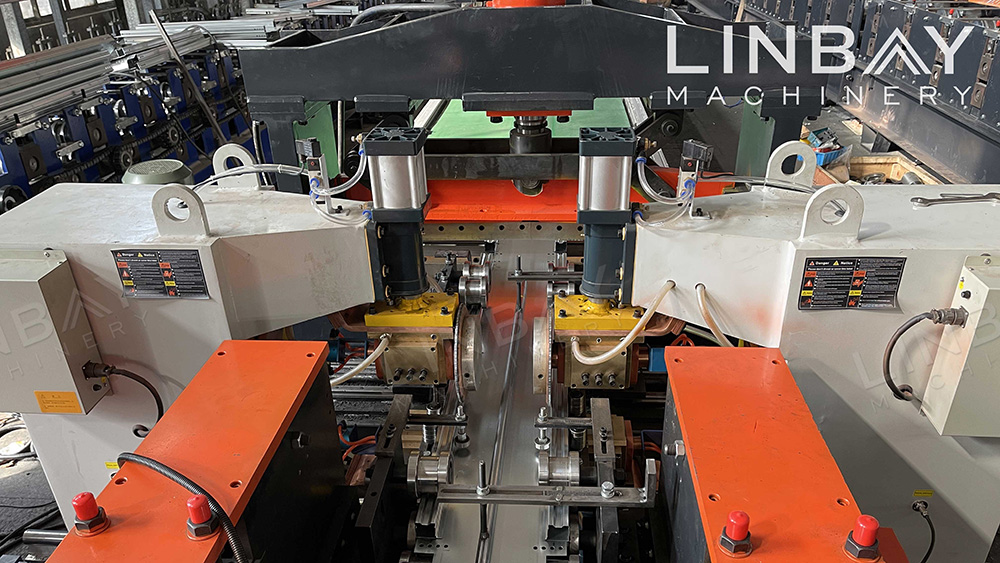

Here we equipped a 2.9kw motor for the servo feeder work with hydraulic punch, it can fasten punch speed and improve the accuracy of punching steps. 2 stands of punch stations can also increase the overall production speed.

The roll forming part we use cantilever chain drive structure, 14 forming stands, 45 steel rollers, φ75mm of diameter for shafts. Motor for the forming is 11kw. With a fixed height, and adjustable width range, customers can produce various sizes products.

Final cutting we design the cut mould with flanging, it can be cut and folded together at the same time which is much convenient for our customers too. We design the cut and fold in one mould so it can reach a double effect.

Also we have experiences in producing double and triple folded shelf panel roll forming machine to fulfill every situations. Welcome to contact us and leave your inquiry.

|

Shelf Panel Roll Forming Machine |

|||

|

NO. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Cold-rolled steel, Galvanized steel, PPGI, stainless steel |

|

|

Thickness(mm):0.6-1mm |

|||

|

Yield strength: 250 - 550MPa |

|||

|

Tensile stress( Mpa):G350Mpa-G550Mpa |

|||

|

2 |

Nominal forming speed(m/min) |

0-10m/min |

Or according to your requirement |

|

3 |

Forming station |

14 |

According to your profile |

|

4 |

Bending station |

2 |

According to your profile |

|

5 |

Decoiler |

5 ton hydraulic decoiler with leveling |

/ |

|

6 |

Main machine motor |

11kw Sino-German Brand |

Siemens |

|

7 |

PLC brand |

Siemens brand |

Panasonic/Delta |

|

8 |

Inverter brand |

Yaskawa brand |

Delta |

|

9 |

Driving system |

Chain drive |

Gear box drive |

|

10 |

Rollers’ materail |

Steel #45 |

Cr12Mov/GCr15 |

|

11 |

Station structure |

Cantilever wall panel |

Iron cast structure |

|

12 |

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

|

15 |

Contactor |

Schneider brand |

Or according to your requirement |

-

Hydraulic punch

-

Transport platform for triple folded shelf panel

-

Triple folded shelf panel

-

Decoiler and leveler

1. Q: Why buy a Linbay machine?

A: Because at Linbay we seek to create relationships that last for years. That's why we offer you the best quality and price, as well as experience and support that is unmatched in the market. We have service in Mexico and China, and we will take care of any questions or inconveniences you may have. In addition, our 12 years in the market support us.

2. Q: What is the delivery time?

A: From 60 to 80 days, after producing and assembling the different components. Depending on your requirements, we must carry out various tests to ensure that your machine meets your expectations and the required safety standards.

3. Q: How do I get started with my machine?

A: Upon the arrival of your machine, you will be given a tutorial on how to assemble it and a manual to learn how to operate it. If this is the first time you buy a forming machine or you have doubts about its operation, it is recommended to visit our technician, who will be in charge of explaining every detail of the machine, as well as training your work team in its operation.

4. Q: I want to buy a machine, but I don't know how to get started? What process should I follow?

A: You can start by sending a message or email to our sales team. You can then describe the type of machine you're looking for and which one best fits your standards. If you want to continue with the process, but have questions about our company, you can visit our office in Mexico or our factory in China, where you can take a tour of our facilities and learn about each manufacturing process of your machine. If you decide to join the Linbay Family, we will start the manufacture of the machine after signing the contracts and making the 30% advance payment.

5. Q: What will the speed of the forming machine depend on?

A: Each design will have a different speed, as if you need to drill or bend, the production time will change. If your shelf has perforations, we recommend the use of a die cutter to help the speed of your product, as well as a hydraulic decoiler, which allows you to feed the die cutter more easily.